Table of contents

Capability Analysis in a Six Sigma Project

Capability analysis is a quantifiable comparison between the Voices of the Customer and the Voices of the Process (limit) data. Process CapaCapability analysis cpk is a quantitative assessment of your ability to meet customer expectations. This is done by comparing the differences between process specifications and variation of process values as determined by 6 process standard deviations.

A process capability analysis can be done using a variety of metrics. The most popular is Capability Index or Cpk. Other metrics that can be calculated include Cp and Kp.

Cpk and Cpk can be used to determine the short-term capabilities of your process. You can also use Ppk and Cpk to do your capability analysis. These are measures of long-term ability. You can see the formulas Cpk, and Ppk for an assumed Normal Distribution.

Only the standard deviation is different in the denominator. Cpk calculates the within-standard deviation using your control chart. Ppk uses an overall standard deviation. These are some differences between Cpk & Ppk.

Cpk:

- Only the variation within subgroups can be accounted for

- It does not account for shifts and drifts between subgroups

- It is sometimes called the potential capability, as it indicates the potential of your process to produce parts within the specification. This assumes that there are no differences between subgroups (i.e. over time)

Ppk:

- This accounts for the variation in all measurements.

- Theoretically, it includes both variation within subgroups as well as the shift and drift among them

- The customer is interested in the long-term capability

What is the purpose of capability analysis?

Capability analysis is a forward-looking measure of your process that attempts to predict the short- and long-term ability of your process in order to meet customer specifications.

Forward-looking Capability analysis is available

Capability analysis is based on historical data and predicts the future capabilities of your process. Because you have historical data, you already know what your current capabilities are and how well you meet your customers’ expectations.

This can be used to determine if there have been any improvements

You can understand the concept of capability metrics and use them to determine if your process has improved relative to customer specifications.

Focus

Capability analysis provides information about the dispersion and centering in your process in relation to customer specifications. This will enable you to either shift the processing center-left or reduce process variation.

Three benefits of capability analysis

Capability analysis can be used to assess how well your company is meeting customers’ specifications, expectations, and needs.

1. Simple calculations

Your statistical software will often do the calculations for Cp, Ppk, and Cpk.

2. Generic evaluation

The capability metrics reflect a process’s ability to meet its specifications. They can be used to compare functions and determine who is performing better or worse than their expectations.

3. It can be used for both continuous attribute and distinct attribute data

Capability analysis can be used to analyze both qualitative and quantitative data. Although the analysis and formulae are different, the concept remains the same.

Our take on Capability Analysis

My team and I at Six Sigma Development Solutions, Inc. are engaged in Lean and Six Sigma projects to work about 60% of the time. We encounter many different opportunities from a variety of disciplines. We are often called in to act as analysis capabilities to an organization that has a continuous improvement system in place. When engaged with the teams at these organizations, I am often witnessing to a team “jumping into the deep weeds” of root cause analysis without understanding if the process is working as was originally engineered to work. If not, where is the delta?

I have an analogy that I like to use in class when teaching the concept of capability analysis. The analogy is called “Closing Open Windows” and is as follows: I drive up to my house open July day when it is 105 degrees Fahrenheit outside. I can hear my condenser (my A/C’s external unit) humming. I have an A/C unit that is rated for a house much larger than mine because I am not fond of the heat. When I enter my house, it is 98 degrees inside. Something is wrong. I check my thermostat and it reads 74 degrees. I check to make sure cold air is being pushed out through my vents. The cold air is effectively being diffused throughout the house. What is the next thing that you would investigate? Most would answer that you would check for open doors and windows. That is the obvious answer, but I see “trained” practitioners first knocking holes in the walls to see if they are missing insulation. They are jumping into a deep root cause analysis without understanding the current state capability of the Inputs.

The reason that Six Sigma practitioners spend time meticulously defining the inputs into the process, in part is to understand what we can measure. Those inputs with variable measurements potentially have tolerances. Those tolerances once understood to be the true voice of the customer, will then help us to understand the capability of the current state of the process inputs. Once we understand both the Stability and Capability (through Capability Analysis) of each of the applicable inputs, this will help us to focus on those inputs with less capability. These inputs will potentially help us to understand the nature of the problem. All of this first depends on a trustworthy measurement system.

The principle of “Occam’s Razor” says that often the simplest answer is the right one. Understand how the process was engineered to operate. Find manuals, SOPs, FMEA, and/or any other documentation. Call the Manufacturer of the machine or cell. Understand what the measurable inputs are in the process and understand their current state capability. Look for “Open Windows” first.

Have you witnessed a team diving into a deep root cause analysis in a Six Sigma project without first looking for “open windows”?

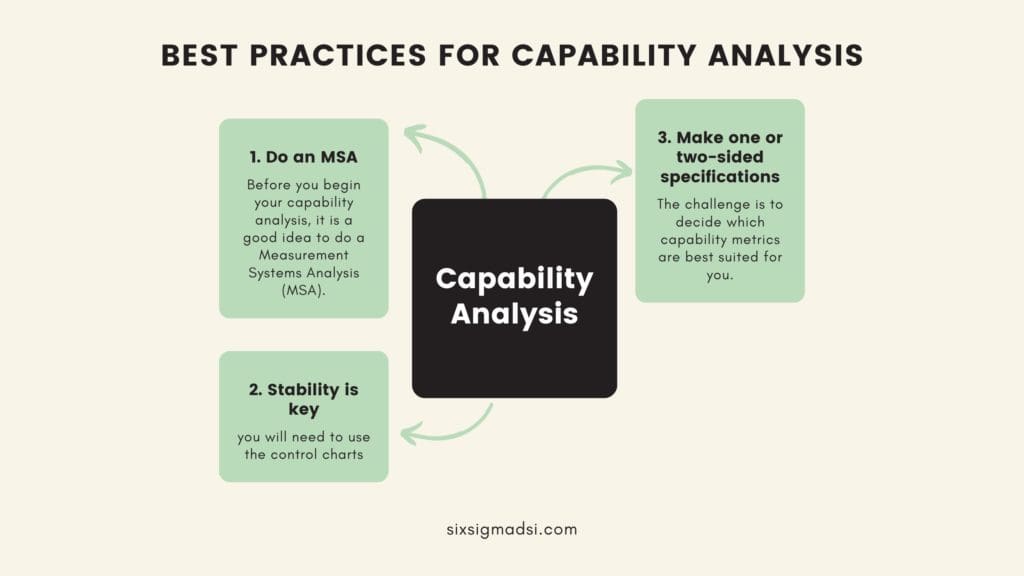

Three best practices for capability analysis

These are some tips to help you do your capability analysis effectively.

1. Do an MSA

You will need to have confidence in your data because of the importance of capability analysis. Before you begin your capability analysis, it is a good idea to do a Measurement Systems Analysis (MSA).

2. Stability is key!

Capability analysis is forward-looking. Therefore, the process must be statistically controlled and show common cause variations. To do this, you will need to use the control charts.

3. It can be used to make one-sided or two-sided specifications

The challenge is to decide which capability metrics are best suited for you. Do you prefer short-term or long-term capability? Is it a one-sided or two-sided spec? Which level of capability are customers requesting?