White Belt training is where individuals begin their Lean Six Sigma journey. It represents a fresh start, like a blank canvas ready to be filled with new knowledge.

The primary goal is to introduce learners to the essential terms and concepts of Lean Six Sigma, enabling them to participate in their organization’s improvement efforts.

Table of contents

- What is a Six Sigma White Belt?

- Benefits of obtaining a White Belt certification

- What is the Expected Salary Range?

- Understanding the Role of a White Belt in Lean Six Sigma

- Potential Candidates for a White Belt

- Industries and job roles that benefit from a White Belt certification

- Key Concepts and Methodologies in Lean Six Sigma White Belt Training

- 6 Tips for Success as a Lean Six Sigma White Belt

- Final Words

- Related Articles:

What is a Six Sigma White Belt?

Have you ever heard of Lean Six Sigma White Belt training? If you’re new to the world of Lean Six Sigma, you might be wondering what this certification entails. In this article, we’ll explore the ins and outs of the Lean Six Sigma White Belt and how it can benefit professionals in various industries.

A Lean Six Sigma White Belt is the first level of certification in the Lean Six Sigma methodology. It introduces the principles and tools used in process improvement and quality management. The White Belt training helps individuals understand the fundamentals of Lean Six Sigma and equips them with basic problem-solving skills.

With a Lean Six Sigma White Belt certification, professionals can contribute to process improvement initiatives in their organizations. This certification demonstrates a commitment to quality and efficiency, making individuals more valuable assets to their teams.

Professionals can also earn Lean Six Sigma Green or Black Belt certifications, which can lead to higher belt ranks and better job positions.

What White Belt Training Covers?

In this training, trainees become familiar with the basic principles of Lean Six Sigma. While White Belt holders may not actively participate in process improvement teams, they gain a foundational understanding of why and how these teams operate.

The training prepares employees to review project processes, understand milestones, and contribute to project selection.

Who Benefits from White Belt Training?

- It provides essential knowledge for support staff to understand Lean Six Sigma projects.

- It is useful for organizations aiming to embed a Six Sigma culture across all levels.

Benefits of obtaining a White Belt certification

Obtaining a Lean Six Sigma White Belt certification offers several benefits for professionals in various industries. Here are some of the key advantages:

- Enhanced problem-solving skills: The White Belt training provides individuals with a structured problem-solving approach, equipping them with the skills to identify, analyze, and solve problems effectively. These skills can be applied to a wide range of situations, leading to improved decision-making and problem-solving abilities.

- Increased efficiency: Lean Six Sigma focuses on eliminating waste and streamlining processes. By understanding the principles and tools of Lean Six Sigma, White Belt-certified professionals can identify and eliminate non-value-added activities, resulting in increased efficiency and productivity.

- Better customer satisfaction: Lean Six Sigma aims to deliver products and services that meet or exceed customer expectations. With a White Belt certification, professionals can contribute to improving customer satisfaction by identifying and addressing issues that affect the quality of products or services.

- Continuous improvement mindset: Lean Six Sigma promotes a culture of continuous improvement. By obtaining a White Belt certification, professionals develop a mindset focused on seeking opportunities for improvement and driving positive change within their organizations.

- Career advancement opportunities: Lean Six Sigma certifications are highly valued in the job market. Having a White Belt certification on your resume can make you stand out from other candidates and open up new career opportunities in fields such as consulting, project management, quality assurance, and operations.

What is the Expected Salary Range?

The salary range of a White belt is estimated in the United States to be USD 40,000 – USD 80,000 depending on location.

Understanding the Role of a White Belt in Lean Six Sigma

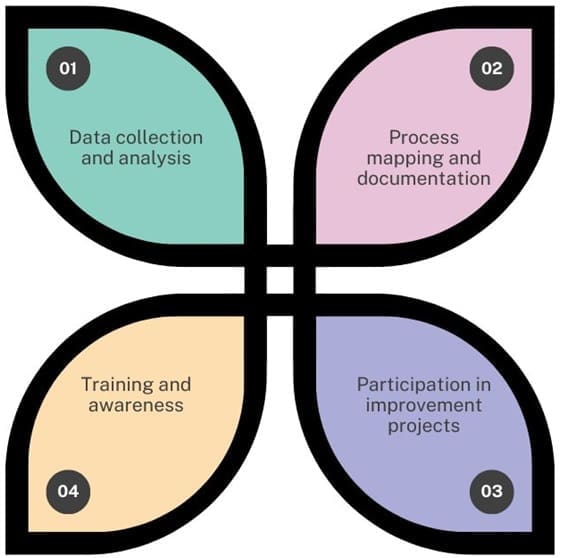

While the White Belt certification is the entry-level certification in Lean Six Sigma, it does not mean that it has a limited role. White Belt-certified professionals play a crucial role in supporting process improvement initiatives within their organizations. Here are some of the key responsibilities of a White Belt:

- Data collection and analysis: White Belt-certified professionals are responsible for collecting and analyzing data related to process performance. They assist in identifying trends, patterns, and areas of improvement based on data analysis.

- Process mapping and documentation: White Belts contribute to process mapping and documentation efforts. They work with teams to understand and document current processes, identify bottlenecks and inefficiencies, and propose improvements.

- Participation in improvement projects: White Belts actively participate in improvement projects led by higher-level Lean Six Sigma practitioners. They contribute to problem-solving sessions, provide input on potential solutions, and support the implementation of improvement initiatives.

- Training and awareness: White Belt-certified professionals serve as ambassadors for Lean Six Sigma within their organizations. They help create awareness of the methodology, educate colleagues on basic Lean Six Sigma concepts and tools, and promote a culture of continuous improvement.

By fulfilling these responsibilities, White Belt-certified professionals contribute to the overall success of process improvement initiatives and help create a culture of continuous improvement within their organizations.

Potential Candidates for a White Belt

Lean Six Sigma professionals can start with Lean Six Sigma White Belt certification training. This training is best for those who are new to Lean Six Sigma and wish to learn more about it and its potential impact on an organization. The following candidates can benefit from the training:

- Managers may be interested in the Lean Six Sigma methodology.

- Professionals who wish to implement basic LEAN practices within their organizations.

- Leaders who recognize the importance of quality improvements.

- Candidates interested in learning the basics of Lean Six Sigma.

- Lean Six Sigma-focused employees work in an organization.

- Anyone who wants to learn the best Lean Six Sigma methodologies and principles.

An employee can gain basic knowledge of Lean Six Sigma through a White Belt certification. Professionals can quickly complete the certification and training.

Industries and job roles that benefit from a White Belt certification

Lean Six Sigma principles and tools can be applied across various industries and job roles. Here are some examples of industries and job roles that can benefit from a White Belt certification:

- Manufacturing: Lean Six Sigma has its roots in the manufacturing industry, where it has been successfully applied to improve production processes, reduce defects, and enhance overall efficiency.

- Healthcare: The healthcare industry faces numerous challenges related to quality, patient safety, and operational efficiency. Lean Six Sigma can help healthcare organizations streamline processes, reduce wait times, and improve patient outcomes.

- Information Technology: IT processes often involve complex workflows and elevated levels of variation. Lean Six Sigma can help IT teams identify and eliminate bottlenecks, reduce defects, and improve service quality.

- Finance and Banking: Financial institutions can benefit from Lean Six Sigma by improving customer service, reducing errors, and streamlining back-office processes.

- Supply Chain and Logistics: Lean Six Sigma can optimize supply chain and coordination processes by reducing lead times, eliminating waste, and improving overall efficiency.

In terms of job roles, individuals in roles such as project managers, process improvement specialists, quality assurance professionals, engineers, consultants, and operations managers can benefit from a White Belt certification. The principles and tools of Lean Six Sigma are applicable across diverse industries, making the White Belt certification valuable for professionals seeking to enhance their problem-solving and process improvement skills.

Also See: Lean Six Sigma in Construction

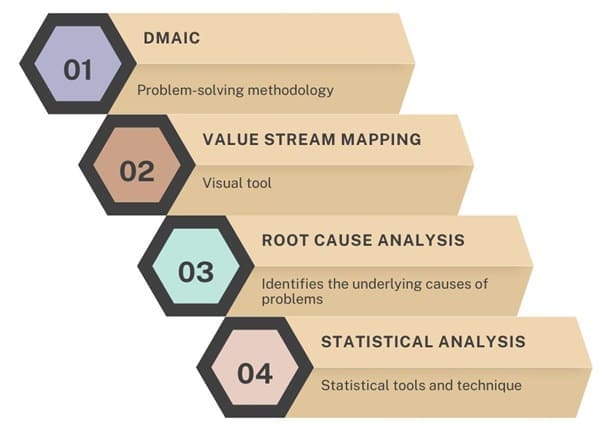

Key Concepts and Methodologies in Lean Six Sigma White Belt Training

To effectively apply Lean Six Sigma principles and tools, it is important to understand the key concepts and methodologies that form the foundation of the methodology. Here are some of the essential elements of Lean Six Sigma:

- DMAIC: DMAIC is a problem-solving methodology widely used in Lean Six Sigma. It stands for Define, Measure, Analyze, Improve, and Control. The DMAIC approach provides a structured framework for identifying and resolving process problems, reducing defects, and improving efficiency.

- Value Stream Mapping: Value Stream Mapping is a visual tool used to analyze and optimize the flow of materials, information, and activities in a process. It helps identify areas of waste, such as unnecessary waiting, excessive inventory, and unnecessary transportation and provides a roadmap for process improvement.

- Root Cause Analysis: Root Cause Analysis is a systematic approach to identifying the underlying causes of problems. It involves asking “why” multiple times to uncover the root cause of a problem and developing appropriate solutions to prevent its recurrence.

- Statistical Analysis: Lean Six Sigma relies on statistical tools and techniques to analyze data and make data-driven decisions. Some common statistical tools used in Lean Six Sigma include control charts, hypothesis testing, regression analysis, and design of experiments.

By mastering these key concepts and methodologies, White Belt-certified professionals can effectively contribute to process improvement initiatives and help drive positive change within their organizations.

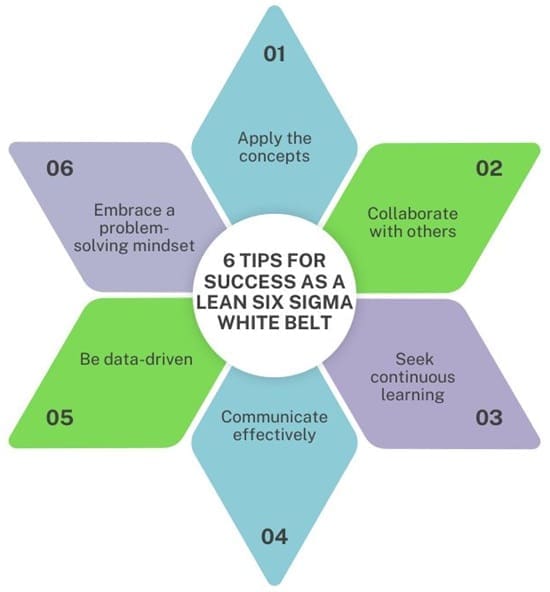

6 Tips for Success as a Lean Six Sigma White Belt

1. Apply the concepts:

Take the time to understand and apply the Lean Six Sigma concepts and tools in your work. Look for opportunities to identify and eliminate waste, reduce defects, and improve processes.

2. Collaborate with others:

Lean Six Sigma is a team effort. Collaborate with colleagues, share ideas, and work together to identify and implement process improvements.

3. Seek continuous learning:

Lean Six Sigma is a continuous journey of learning and improvement. Stay updated with the latest trends and developments in Lean Six Sigma and continue to enhance your skills through additional training and certifications.

4. Communicate effectively:

Effective communication is crucial for successful Lean Six Sigma projects. Clearly articulate problems, potential solutions, and the impact of process improvements to stakeholders at all levels.

5. Be data-driven:

Lean Six Sigma relies on data to drive decision-making. Collect and analyze data to identify patterns, trends, and areas for improvement. Base your decisions on factual evidence rather than assumptions.

6. Embrace a problem-solving mindset:

Lean Six Sigma is all about problem-solving. Embrace a mindset that sees problems as opportunities for improvement, and approach challenges with a structured problem-solving approach.

By following these tips, you can make a significant impact as a Lean Six Sigma White Belt. Also, you can contribute to the success of process improvement initiatives within your organization.

Final Words

It offers a very basic overview of Lean Six Sigma. Further, it is sometimes not recognized as a formal certification by all Six Sigma professionals.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.