The Certified Six Sigma Yellow Belt (CSSYB) certification serves as an entry point into the Six Sigma methodology. Designed for individuals new to this process improvement framework, it is suitable for both entry-level employees aiming to enhance their work environment and executive champions seeking an overview of Six Sigma and its Define, Measure, Analyze, Improve, and Control (DMAIC) model.

The Six Sigma Yellow Belt certification is the introductory level in the Six Sigma certification hierarchy. It is designed for individuals who are new to the Six Sigma methodology and who have a small role, interest, or need to develop foundational knowledge in this area.

Six Sigma is a set of techniques and tools for process improvement, widely recognized for its ability to enhance business processes by reducing errors and increasing quality.

Table of contents

What is a Lean Six Sigma Yellow Belt?

The Six Sigma Yellow Belt certification introduces participants to the fundamentals of Six Sigma. A Lean Six Sigma Yellow Belt certification can be achieved by anyone who is new to the methodology and has a passion for learning. Entry-level employees who wish to learn more about Lean Six Sigma or the DMAIC process can become a Yellow Belt by taking a 2-day (16-hour) training.

Certified Lean Six Sigma Yellow Belt professionals will be able to understand the concepts of Six Sigma and LEAN and assist the Green and Black Belts in projects. They are responsible for small projects that are managed using a simplified roadmap called PDCA (Plan, Do, Check, Act), or they can serve as a team member in more complex improvement projects led by a Certified Green Belt or Certified Black Belt, typically in a part-time role.

Who Should Pursue Six Sigma Yellow Belt Certification?

The Six Sigma Yellow Belt certification is suitable for:

- Entry-Level Employees: Individuals at the beginning of their careers who seek to improve their work processes and contribute to their organizations’ success.

- Executive Champions: Leaders and executives who require a basic understanding of Six Sigma to support and champion process improvement initiatives within their organizations.

- Professionals New to Six Sigma: Anyone interested in gaining a foundational understanding of Six Sigma principles and methodologies.

Importance of Six Sigma Yellow Belt

Obtaining a Six Sigma Yellow Belt certification offers several important benefits:

- Foundational Knowledge: Provides a strong introduction to Six Sigma principles, including the DMAIC (Define, Measure, Analyze, Improve, Control) methodology.

- Career Advancement: Enhances resumes and opens doors to higher-level Six Sigma certifications such as Green Belt and Black Belt.

- Organizational Impact: Empowers individuals to contribute to process improvement projects, which can lead to cost reductions, increased revenue, and improved product and service quality.

What are the Responsibilities of a Lean Six Sigma Yellow Belt?

- Lean Six Sigma Yellow Belt certification provides an overview of Lean Six Sigma and basic improvement methods.

- Certified individuals can use Lean Six Sigma methods to improve production and transactional systems.

- They aim to meet customer expectations and achieve organizational goals.

- Yellow Belt professionals improve systems to better meet customer and organization expectations.

- They can join core project teams and handle small-scale process improvement projects using the PDCA process.

- Small-scale projects can be escalated to Black Belt or Green Belt levels for advanced improvements.

- Training introduces basic Six Sigma tools and process management.

- This helps candidates understand processes and contribute to organizational goals.

- They receive an overview of Lean Six Sigma methodology to align with company goals.

Key Concepts in Yellow Belt Training

| Topic | Description |

| Six Sigma Roles | Understanding the various roles within a Six Sigma project team. |

| Team Development and Management | Basics of team dynamics and leadership within Six Sigma projects. |

| Quality Tools | Introduction to essential tools such as Pareto charts, run charts, scatter diagrams, and histograms. |

| Six Sigma Metrics | Familiarity with common metrics used to measure process performance. |

| Data Collection | Techniques and strategies for effective data gathering. |

| Measurement System Analysis | Ensuring the accuracy and reliability of data collected. |

| Root Cause Analysis | Identifying the underlying causes of process issues. |

| Introduction to Hypothesis Testing | Basic understanding of hypothesis testing and its significance in process improvement. |

Contributions of a Yellow Belt

Yellow Belts support Six Sigma projects led by Green or Black Belts. They assist in data collection, analysis, and process mapping, contributing to cost reduction and quality improvement. Their consistent adherence to quality standards helps improve overall organizational performance.

Certification Details

Requirements

There are no specific educational or experience prerequisites for the Six Sigma Yellow Belt certification, making it accessible to anyone interested in acquiring foundational knowledge of Six Sigma.

Examination

The certification exam for the Six Sigma Yellow Belt typically includes multiple-choice questions covering various aspects of the DMAIC methodology and basic quality tools. For example, the IASSC Certified Lean Six Sigma Yellow Belt Exam™ consists of 60 questions with a two-hour time limit. A passing score of 70% is required.

Preparation for Certification

While there are no formal prerequisites, it is recommended that candidates undergo training through qualified institutions, trainers, or corporate programs. Some certification bodies also offer non-proctored evaluation exams to help candidates assess their readiness.

Benefits of Lean Six Sigma Yellow Belt Certification to Professionals

Boost Your Resume!

Employers want team members with Lean Six Sigma certification for growth. It shows you know basic root cause analysis tools and follow the DMAIC process.

High Salary Potential

The certification doesn’t guarantee a higher wage, but it makes you more valuable to employers. They seek candidates with a range of skills. Lean Six Sigma Yellow Belt gives you an edge over those without it.

Solve Simple Problems

Yellow Belts use a structured method to tackle and solve localized problems by addressing root causes, improving business performance and team morale.

Quick Certification

Lean Six Sigma Yellow Belt training usually takes two working days. You won’t be away from your business for long, and it’s a good step towards Green or Black Belt qualifications.

Boost Project Success

Having Lean Six Sigma Yellow Belts working with Green or Black Belt leaders increases the chances of successful project delivery. They help carry out the project work effectively.

Promote Continuous Improvement

Training more people in Lean Six Sigma Yellow Belt creates a culture of continuous improvement. It takes less time and costs less than Green or Black Belt training.

Understand Roles and Responsibilities

Yellow Belts understand the roles and responsibilities of Lean Six Sigma team members. They know basic tools like FMEA, C&E Matrix, VSM, and Standard Deviation, and can support higher-level belts on process improvement teams.

Benefits of Lean Six Sigma Yellow Belt to an organization

Lean Six Sigma can improve your business operations in many ways.

Customer Satisfaction

Customer satisfaction measures how happy a client is with a product. Lean Six Sigma improves processes and quality control, resulting in a better product and happier customers.

Customer Loyalty

Satisfied customers come back for more. Consistent quality helps build loyal clients.

Improved Bottom-Line

Happy customers spread positive word-of-mouth and return for more purchases, increasing revenue.

Employee Satisfaction

Lean Six Sigma unites employees with a common goal. It helps leaders clearly communicate their message, fostering team spirit and leading to better results.

Better Collaborations

A successful company benefits other companies it works with, leading to long-term partnerships and the adoption of Lean Six Sigma methods.

Lean Six Sigma Yellow Belt, Is it worth it?

- A Lean Six Sigma Yellow Belt certification is a cost-effective and time-efficient way to become more valuable to your organization.

- Normally a 16-hour course.

- You will learn skills and knowledge that you can immediately use to solve problems in your everyday work environment.

- The price for training is usually cost-effective when compared to the other more advanced Lean Six Sigma certifications.

- Our Lean Six Sigma Yellow Belt certification is a globally recognized certification.

- It is a stepping-stone to other more advanced Lean Six Sigma certifications like the Green Belt and the Black Belt.

What is the Salary of a Lean Six Sigma Yellow Belt?

According to Indeed, depending on their location, experience and employer, professionals with a Six Sigma yellow belt may earn between $70,000 and $80,000 per year, and the national average salary for a Lean Six Sigma specialist is $99,653 per year.

How do I get certified as a Lean Six Sigma Yellow Belt?

Certification by the International Association for Six Sigma Certification

The IASSC Yellow Belt is a proctored, closed-book exam that has 60 questions. There are two hours of time allowed. This is the first level of a hierarchy for education and training in both Lean Six Sigma (Six Sigma) and Lean Six Sigma. The Yellow Belt is a Level 3 qualification or “Advanced apprenticeship”, which is equal to two A-levels. This is a basic introduction of Lean Six Sigma methods.

The Yellow Belt is an excellent certification for team members and team leaders who are dealing with problems that arise in the local area. It can open the door to process improvement.

Both the IASSC Lean Six Sigma standards and certifications and ASQ Lean Six Sigma standards and certifications are widely recognized and respected in the Lean Six Sigma Industry.

The certification program is designed to be completed in one to three weeks by users who are new to the system.

Certification by The American Society for Quality (ASQ)

The ASQ Six Sigma Yellow Belt is a certification that will qualify you for a variety of positions within the business world. This is the first level of a hierarchy for education and training in both Lean Six Sigma as well as Six Sigma. In many industries, the certification is regarded as a sign of excellence in quality.

Non-members pay $394, while members pay $294. The cost of retaking the exam is $184. The 90-question exam has a duration of 2 hours and 18 minutes. The exam is scored 80/100.

This certification will allow you to qualify for more positions in modern business environments. The certification can also demonstrate your commitment to improve your analytical and business skills.

Certification through Six Sigma Development Solutions, Inc.

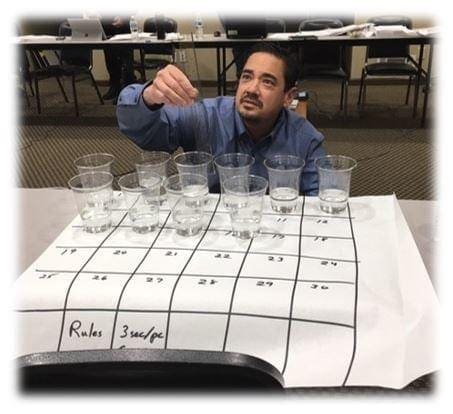

Six Sigma Development Solution, Inc.’s 2-day Lean Six Sigma Yellow Belt certification course is fun and interactive, using games, videos, and simulations. We use dice, Legos, and airplanes to make learning exciting, so you won’t be sitting down for long.

Course Highlights

- Engaging Activities: Hands-on activities with dice, Legos, and airplanes.

- Basic Concepts: Learn the basics of Lean and Six Sigma.

- Team Involvement: Become a core team member or subject matter expert on Lean Six Sigma projects.

- Root Cause Analysis: Use Yellow Belt tools for detailed root cause analysis.

- Project Charter: Create a project charter using a “Quad Chart.”

- SIPOC: Use SIPOC to verify focus.

- Value Stream Map: Identify waste with Value Stream Mapping.

- Quick Change Process Map: Develop a detailed process map.

- Fishbone Diagrams: Find the root causes of issues.

- Project Planning: Identify and prioritize improvements and create a project plan.

Course Contents

- Overview of Lean and Six Sigma Concepts

- Using Pareto Charts to Focus the Project

- Developing the Project Charter

- Showing Baseline Statistical Control and Capability

- Completing SIPOC for Correct Focus

- Value Stream Mapping to Identify Waste

- Quick Change Process Mapping Technique

- Root Cause Analysis with Fishbone Diagrams

- Selecting, Managing, and Controlling Solutions

- Showing Improved Statistical Control and Capability

Career opportunities and advancement with a Yellow Belt certification

Yellow Belt certification opens doors to roles like Business Optimization Specialist, Supply Chain Manager, Process Analyst, Continuous Improvement Manager, Continuous Quality Engineer, Operations Manager, Six Sigma Analyst Consultant, and Process Improvement Analyst.

Yellow Belts can join project teams, create process maps, and manage smaller improvement projects using the PDCA framework.

Certified Yellow Belts can work in IT, sales, marketing, HR, quality assurance, accounting, and customer service.

They improve stakeholder management and communication by finding root causes of problems and managing performance with verified data.

Why Choose Six Sigma Development Solutions?

Six Sigma Development Solutions stands out due to its commitment to delivering high-quality training and support. They focus on ensuring that participants not only pass the certification exam but also effectively apply their knowledge in real-world scenarios.

Our comprehensive approach to training and post-certification support makes us a preferred choice. We are ideal for individuals and organizations looking to implement Six Sigma methodologies successfully.

Final Words

The Certified Six Sigma Yellow Belt (CSSYB) certification is an essential step for those beginning their journey with Six Sigma. It provides a robust foundation in the DMAIC methodology and equips individuals with the skills necessary to support and contribute to process improvement projects.

Whether you are an entry-level employee or an executive champion, obtaining a Yellow Belt certification from Six Sigma Development Solutions is a valuable step. This certification enhances your understanding of Six Sigma and its application in achieving operational excellence.

Learn more about our Lean Six Sigma Yellow Belt certification

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.

Hello

Is there any weekend classes for the yellow belts

Eric, Good afternoon. We only offer Lean Six Sigma Yellow Belt training onsite at your organization for up to 20 people for two consective days on Monday – Friday. We are in the process of creating an online on-demand Six Sigma Yellow Belt training course.

Eric, we have recently developed an online on demand Lean Six Sigma Yellow Belt certification (https://sixsigmadsi.com/product/online-lean-six-sigma-yellow-belt-certification/). This is the same course that we provide in-person to our corporate clients.