The term “Green Belt” is more than just a color; it signifies a specific level of proficiency and responsibility within the Six Sigma framework, drawing an analogy from martial arts ranking systems.

It represents a practitioner who has moved beyond basic awareness (often represented by “White Belt” or introductory training) but is still developing the mastery of a “Black Belt.” Green Belts are the core implementers of Six Sigma methodologies on the ground.

The Six Sigma Green Belt certification represents a significant step beyond basic quality awareness. It signifies a professional who has not only grasped the core tenets of the Six Sigma methodology but also possesses the practical skills to actively participate in, and often lead, process improvement initiatives.

These individuals are the engine room of many continuous improvement efforts, equipped to tackle complex problems within their operational spheres.

Table of contents

- What Is Six Sigma Green Belt?

- Mastery of Key Tools and Techniques

- DMAIC Methodology Explained

- Strategic Importance of Green Belt for Organizations

- Certification Requirements and Process

- Career Opportunities and Salary Outlook

- Green Belt vs. Other Six Sigma Levels

- Distinguishing Green Belts from Other Belts

- Tools and Software Utilized

- Salary of Six Sigma Green Belt

- Frequently Asked Questions

- Final Words

- Related Articles

What Is Six Sigma Green Belt?

A Six Sigma Green Belt is a professional trained in the DMAIC methodology (Define, Measure, Analyze, Improve, Control) to lead or support process improvement projects within an organization. While they may not lead large-scale initiatives like Black Belts, Green Belts play a crucial role in driving quality improvements and operational efficiency.

Public, Onsite, Virtual, and Online Six Sigma Certification Training!

- We are accredited by the IASSC.

- Live Public Training at 52 Sites.

- Live Virtual Training.

- Onsite Training (at your organization).

- Interactive Online (self-paced) training,

Journey to Certification

Achieving Green Belt certification typically involves a structured training program that can range from several days to a few weeks, followed by the successful completion of a real-world improvement project. The curriculum delves into statistical tools, problem-solving methodologies, and team dynamics.

Certification often requires demonstrating practical application of these concepts through the project, showcasing the ability to drive measurable improvements.

Key Responsibilities

- Project Leadership: Lead small to medium-sized Six Sigma projects or support Black Belts in larger initiatives.

- Data Analysis: Utilize statistical tools to analyze data and identify root causes of process inefficiencies.

- Process Improvement: Implement solutions to enhance process performance and reduce variability.

- Team Collaboration: Work with cross-functional teams to ensure successful project execution.

- Reporting: Communicate project progress and results to stakeholders.

Also See: IASSC Certified Lean Six Sigma Green Belt Mock Exam

Essential Skills

- Statistical Analysis: Proficiency in tools like Minitab, Excel, or other statistical software.

- Problem-Solving: Ability to identify issues and develop effective solutions.

- Project Management: Skills to plan, execute, and monitor projects.

- Communication: Clear and concise reporting to stakeholders.

- Lean Methodology: Understanding of waste reduction techniques and process optimization.

Mastery of Key Tools and Techniques

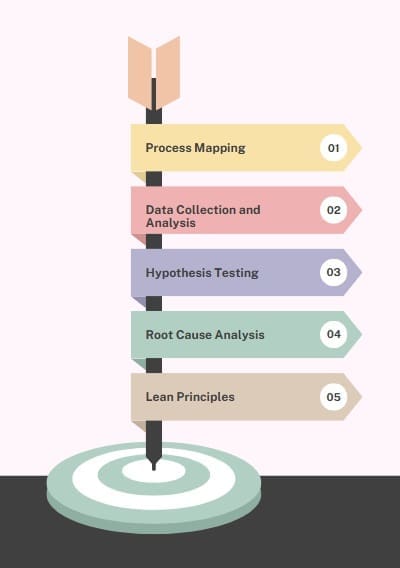

Green Belts are proficient in a range of statistical and problem-solving tools. This isn’t just theoretical knowledge; they can actively apply these tools in real-world scenarios. Expect them to be comfortable with:

- Process Mapping: Visually representing process flows to identify areas for improvement.

- Data Collection and Analysis: Gathering relevant data and using basic statistical tools like histograms, Pareto charts, and control charts to understand process performance.

- Hypothesis Testing: Formulating and testing assumptions about the causes of variation.

- Root Cause Analysis: Employing techniques like the “5 Whys” and fishbone diagrams to pinpoint the fundamental issues.

- Lean Principles: Understanding and applying concepts like value stream mapping and waste reduction to enhance efficiency.

DMAIC Methodology Explained

The DMAIC framework is central to Six Sigma projects:

- Define: Identify the problem, project goals, and customer requirements.

- Measure: Collect data to establish baselines and understand current performance.

- Analyze: Examine data to identify root causes of issues.

- Improve: Develop and implement solutions to address root causes.

- Control: Establish controls to sustain improvements and monitor performance.

Also See: IASSC Lean Six Sigma Green Belt Examination Voucher

Strategic Importance of Green Belt for Organizations

Organizations that strategically develop and deploy Six Sigma Green Belts realize significant and multifaceted benefits:

- Enhanced Problem-Solving Capabilities: A larger pool of trained individuals equipped with data-driven problem-solving skills distributed across the organization.

- Accelerated Improvement Velocity: More improvement projects can be initiated and completed concurrently, leading to a faster rate of overall organizational improvement.

- Data-Driven Decision Making: A greater reliance on data and facts rather than assumptions in operational decision-making.

- Cost Reduction and Efficiency Gains: Tangible financial benefits resulting from reduced defects, waste, and process variation.

- Improved Quality and Customer Satisfaction: Processes designed for consistency and minimal defects lead to higher quality products and services, ultimately enhancing customer satisfaction and loyalty.

- A Foundation for Future Leaders: Green Belt certification serves as a crucial stepping stone for individuals aspiring to more advanced roles in continuous improvement, such as Black Belt or Master Black Belt.

Certification Requirements and Process

Certification Bodies:

- ASQ (American Society for Quality): Offers the Certified Six Sigma Green Belt (CSSGB) certification.

- IASSC (International Association for Six Sigma Certification): Provides the Lean Six Sigma Green Belt certification.

ASQ Certification Requirements:

- Experience: Minimum of 3 years of work experience in one or more areas of the Certified Six Sigma Green Belt Body of Knowledge.

- Exam Fee: ₹30,650 for ASQ members; ₹38,950 for non-members.

- Exam Format: 100 multiple-choice questions, 4-hour duration.

Note: Educational waivers are not granted for this exam.

IASSC Certification Requirements:

- Experience: No work experience required.

- Exam Fee: $295 USD.

- Exam Format: 100 multiple-choice questions, 3-hour duration.

Career Opportunities and Salary Outlook

Potential Job Roles:

- Project Manager: Oversee and manage Six Sigma projects.

- Quality Manager: Ensure products and processes meet quality standards.

- Process Improvement Consultant: Advise organizations on process optimization.

- Operations Manager: Manage day-to-day operations to enhance efficiency.

- Supply Chain Manager: Oversee and improve supply chain processes.

Salary Expectations:

- United States: Average annual salary ranges from $96,600 to $125,800, depending on experience and location.

- India: Average annual salary ranges from ₹8,00,000 to ₹15,00,000, varying by industry and region.

- United Kingdom: Average annual salary ranges from £45,000 to £60,000.

Note: Salaries can vary based on industry, company size, and geographic location.

Also See: Lean Six Sigma Green Belt Salary

Green Belt vs. Other Six Sigma Levels

| Level | Focus Area | Role in Projects | Prerequisites |

| Yellow Belt | Basic understanding | Team member | None |

| Green Belt | Data analysis & project leadership | Project leader/support | Some experience helpful |

| Black Belt | Advanced analysis & strategy | Senior project leader | Green Belt certification |

| Master Black Belt | Organization-wide strategy | Coach/mentor/expert | Black Belt required |

Distinguishing Green Belts from Other Belts

Understanding the hierarchy is crucial:

- White Belt: Possesses basic awareness of Six Sigma concepts and principles. Often participates in teams but doesn’t lead projects.

- Yellow Belt: Has a more in-depth understanding of specific improvement methodologies and tools. May support Green and Black Belt projects.

- Green Belt: Leads or co-leads improvement projects within their functional area, applying the DMAIC methodology and a range of statistical tools.

- Black Belt: Leads complex, high-impact improvement projects across the organization. Possesses a more advanced statistical skillset and often mentors Green Belts.

- Master Black Belt: Champions Six Sigma across the organization, develops strategy, mentors Black Belts, and acts as a technical resource.

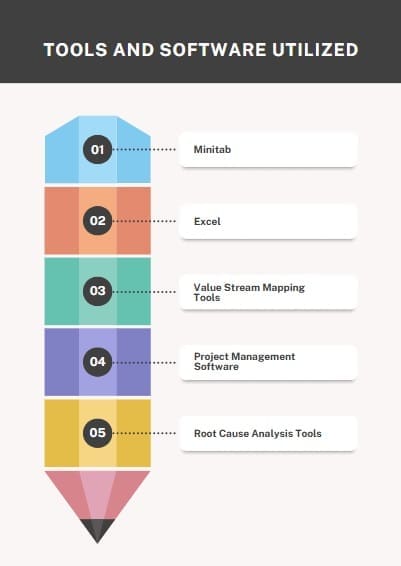

Tools and Software Utilized

Green Belts often employ various tools to facilitate process improvement:

- Minitab: Statistical software for data analysis.

- Excel: Widely used for data collection and basic analysis.

- Value Stream Mapping Tools: Tools like Lucidchart or Visio to visualize processes.

- Project Management Software: Tools like Trello, Asana, or Jira to manage tasks and timelines.

- Root Cause Analysis Tools: Techniques like Fishbone diagrams or 5 Whys to identify underlying issues.

Also See: Lean Six Sigma Green Belt Project Management Kit

Salary of Six Sigma Green Belt

As of May 2025, the average annual salary for a Six Sigma Green Belt in the United States typically ranges from $91,000 to $135,000. However, several sources provide slightly different figures, so it’s helpful to look at a range:

- Average: Most sources indicate an average annual salary in the range of $114,700 to $116,900.

- Salary Range: You can generally expect a salary between $88,000 on the lower end to $135,000 on the higher end, with some reporting ranges extending even further.

Factors Influencing Salary in the US

Similar to India, several factors affect the earning potential of a Six Sigma Green Belt in the United States:

- Experience Level:

- Entry-Level (0-2 years): Around $108,000 – $110,000 per year.

- Mid-Career (2-4 years): Around $111,000 – $112,000 per year.

- Experienced (5-8+ years): Can reach $113,000 – $115,000 or more per year.

- Location: Metropolitan areas with a higher cost of living and greater demand for skilled professionals often offer higher salaries. For example, salaries in California, Massachusetts, and New Jersey tend to be above the national average. Cities like San Francisco and New York City often have even higher salary averages.

- Industry: Industries like manufacturing, healthcare, finance, technology, and engineering highly value Six Sigma professionals, which can translate to higher salaries.

- Job Role: Specific job titles held by Green Belts command different salaries. Examples include:

- Quality Engineer: Around $104,000 per year.

- Process Engineer: Around $84,000 per year.

- Quality Manager: Can range widely, but averages around $104,000 per year.

- Operations Manager: Around $121,000 per year.

- Project Manager: Can average around $143,000 per year.

- Continuous Improvement Manager: Can average around $115,000 – $135,000 per year.

- Company Size and Reputation: Larger and more established companies may offer higher compensation packages.

- Additional Skills and Certifications: Complementary skills in areas like project management, data analytics, and leadership, as well as advanced certifications like Black Belt, can significantly increase earning potential.

Frequently Asked Questions

1. Is Six Sigma Green Belt certification worth it?

Yes, obtaining a Green Belt certification can enhance your problem-solving and project management skills, making you a valuable asset to employers seeking process improvement.

2. How long does it take to achieve certification?

The duration varies based on the certification provider and your prior knowledge. Typically, preparation can take 4–8 weeks.

3. Does the certification expire?

Certification validity depends on the provider. For instance, ASQ certifications require renewal every 3 years, while IASSC certifications are valid for life.

4. Do I need prior work experience?

ASQ requires a minimum of 3 years of work experience, whereas IASSC does not have this requirement.

Final Words

Pursuing a Six Sigma Green Belt certification in 2025 can significantly enhance your career prospects in various industries, including manufacturing, healthcare, finance, and IT. By equipping yourself with the skills to lead data-driven process improvements, you position yourself as a key contributor to organizational success.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.