Lean Six Sigma

Green Belt

Certification Programs

Training Sites Globally

Green Belts Trained

Million $ in Savings

Star Review Rating

“Our instructor for the Lean Six Sigma Green Belt course was excellent. She was extremely energetic and did a great job pacing her delivery in accordance with our needs. She also went out of her way to accommodate our need to utilize Excel and Minitab for some of the statistical analysis and to share some specific, real-world examples. She excelled at making complex subjects clear.

I highly reccommend this Lean Six Sigma Green Belt course to anyone who wants to have an impact to their organization.”

What is a Lean Six Sigma Green Belt?

Lean Six Sigma Green Belts are employees who have been trained in Green Belt level improvement methods and will be leading continuous process improvement groups as part of their regular job. This allows for more time by company leaders and champions to be spent on strategy building and decision-making components of the Lean Six Sigma project planning process. The Green Belts are better able to understand the entire process and work closely with subject matter experts (SMEs) to achieve performance goals.

Depending on the organization, Lean Six Sigma Green Belts can expect to spend between 10-25% of their time on Lean Six Sigma projects. Lean Six Sigma Green Belts are responsible for data collection and analysis within their project teams. Facilitation skills and the ability to lead root cause analysis sessions help them improve team dynamics and function.

Salary of a Lean Six Sigma Green Belt

Companies around the globe are looking for Lean Six Sigma Green Belts to reduce costs and eliminate waste. The Green Belt is a valuable investment. They are recognized by employers as an investment because they have been trained to use Lean Six Sigma tools and methodologies to avoid defects and improve customer satisfaction.

A 2016 publication revealed the salaries of Lean Six Sigma Green Belt certified employees. The data showed that New York had the highest median annual salary of $92,510. Houston was next with $86,375, and Minneapolis with $84,181.

According to the Average Salary by State or Province for Certified Lean Six Sigma Green Belt: California had the highest annual median salary with $88,114. Texas was next at $81,842 and Michigan $73,560, respectively. This is a list of seven states and provinces.

With the arrival of 2022, Lean Six Sigma will be more important than ever. It is anticipated that the median annual salary in the United States will reach $110,000.

Lean Six Sigma Green Belt Certification Program

The certification program is for professionals who have little to no previous experience with Lean Six Sigma. The course provides an overview of the techniques, tools and methods that can be used to help lead Lean Six Sigma projects within their organizations. The problem-solving framework is Define, Measure Analyze, and Improve, Control (DMAIC). Students also learn how to use the quantitative (statistical) and qualitative tools to streamline production and services. Lean Six Sigma Green Belts have the skills and knowledge to successfully lead a Lean Six Sigma Green Belt-level project that reduces or eliminates waste, lowers defects in products and processes, and improves customer satisfaction.

Lean Six Sigma Green Belt course includes

- Lean and Six Sigma Overview

- How to Select the Right Lean Six Sigma Projects

- How to Develop the Lean Six Sigma Project Charter

- The SIPOC Diagram (Verify Your Project Focus)

- Learn How to use Value Stream Mapping to Quickly Identify Waste in the Process

- Developing the X-Map (or Input Map) to Discover the Key Inputs to Your Process)

- Developing the Cause and Effects Matrix to Prioritize Key Inputs

- How to Complete the Failure Modes and Effects Analysis (FMEA) to Manage Risk

- Brush up on Basic Statistics

- Learn the Basic Graphical Stats Tools (Pareto Charts, Boxplots, Scatter Plots)

- How to Define your Processes Capability in Metrics

- How to Turn a Practical Question into a Statistical Question (or Hypothesis)

- How to Understand the Statistical Relationship between two variables

- How to Control Your Process using SPC (Statistical Process Control)

“I thought the training on all of the quantitative statistical tools was most beneficial to me. I was afraid of stats before I took the class, but now I am more confident analyzing data.

The way that the instructor taught the concepts along with the application in Minitab allowed me to grasp the material a lot easier and faster than traditional statistics courses at a university.

Everything we were taught in class is out on Six Sigma Development Systems website and YouTube channel for reference 24/7.”

We help you complete your project

Six Sigma Development Solutions, Inc. will provide you with a detaiiled DMAIC roadmap to guide you through your project. We also provide you with a Master Black Belt mentor to work with you throughout your project.

- A Tollgate (Checklist) and a Well Defined Flowchart for Project Completion.

- Example of the Lean Six Sigma Green Belt “Define Phase” tollgate

- An SSDSI Master Black Belt to mentor you through your complete Green Belt Certification project cycle.

- A PowerPoint Template with Detailed Instructions on how to Complete your Final Project Presentation

- A Customized plan and roadmap of how to complete your individual project within three months.

What kind of time will the course require?

The Lean Six Sigma Green Belt Certification Course is a hybrid of online and traditional classroom courses. The Lean Six Sigma Green Belt Certification Course is broken into three sections:

- 20 hours of pre-classroom preparation requirements,

- 40 hours or five days (excluding lunch and hourly 10 minute breaks) of live (in person) or virtual classroom sessions,

- 20 hours (or more) of post-classroom Lean Six Sigma certification requirements

Detail of time requirements:

Section #1: 20 hours of pre-classroom preparation requirements

- You will be required to review several interactive video’s introducing you to the Lean and Six Sigma Methodologies.

- During our pre-class preparation, we will work with you define a properly scoped (manageable) Lean Six Sigma project.

You will be pointed to instructional articles and video’s to help with Charter development

- We will also work with you to collect proper data to use in the live classroom sessions

You will be directed to instructional articles on how to develop a multi-vari data collection sheet

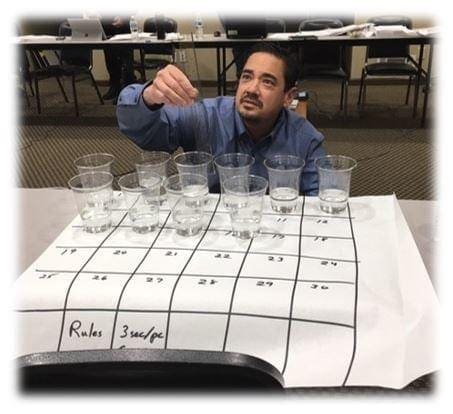

Section #2: 40 hours or five days (excluding lunch and hourly 10 minute breaks) of live (in person) or virtual classroom sessions.

Section #3 20 hours (or more) of post-classroom Lean Six Sigma certification requirements

- Our Master Black Belt Mentors will be your resource to Mentor and Champion you through the five DMAIC tollgates provided.

- You will be given access to several educational resources (online articles, videos and books) during the classroom session to aid throughout the certification process.

Don't worry, you are in great company!