Table of contents

- An Intro to Measurement System Analysis

- What is it?

- What is a Measurement System and how does it work?

- How to Identify a Measurement Systems error?

- Why Perform a Measurement System Analysis (MSA)?

- How it’s done (the MSA)?

- Variable vs. Attribute Data Classifications

- The Variable Gage R&R (Repeatability and Reproducibility) Study

- When do you need a Variable Gage R&R Study?

- Attribute Gage R&R (often called Attribute Agreement Analysis)

- Why is MSA important?

- Related SSDSI Articles

An Intro to Measurement System Analysis

Today, data is being used in more ways than ever by businesses. Organizations around the globe have access to vast amounts of data through inspection and measurement. It is crucial that this measurement data be reliable when it is used to make business decisions. We will make poor decisions if our measurement system is flawed. An accurately planned and executed Measurement Systems Analysis (MSA), can provide a solid foundation for effective data-based decision-making.

What is it?

MSA can be described as an experimental and mathematical way to determine the degree of variation in a measurement process. Variations in the measurement process can directly impact our overall process variability. MSA is used for certification of the measurement system by evaluating its stability, precision, and accuracy.

What is a Measurement System and how does it work?

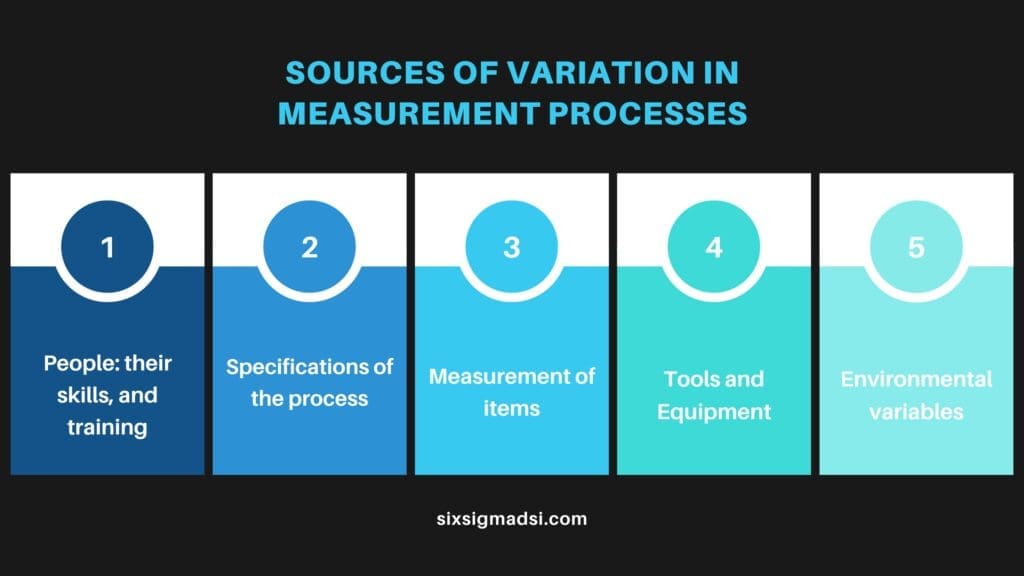

Before we get into MSA, let’s review the definition and sources of variation. A measurement system is a collection of related measures that allow the identification (and quantification) of specific characteristics. It may also contain a set of tools that are required to validate or assess a specific unit of measurement. These are some examples of sources of variation in measurement processes:

- People – The operators, their skills, and training

- Specifications of the process (incorrect specs or no specs)

- Measurement of items – The part or material samples to be measured or the sampling plan

- Tools and Equipment: This could Gages or test equipment, as well as calibration systems

- Environmental variables like humidity, noise, temperature, etc.

During Measurement System Analysis, all these potential sources of variation must be considered. Specific quality tools should be used to determine the source of variation when evaluating a measurement system. Two primary sources of variation are examined in most MSA activities: the measurement and the parts. These two values are the total variation in a measurement method.

How to Identify a Measurement Systems Error?

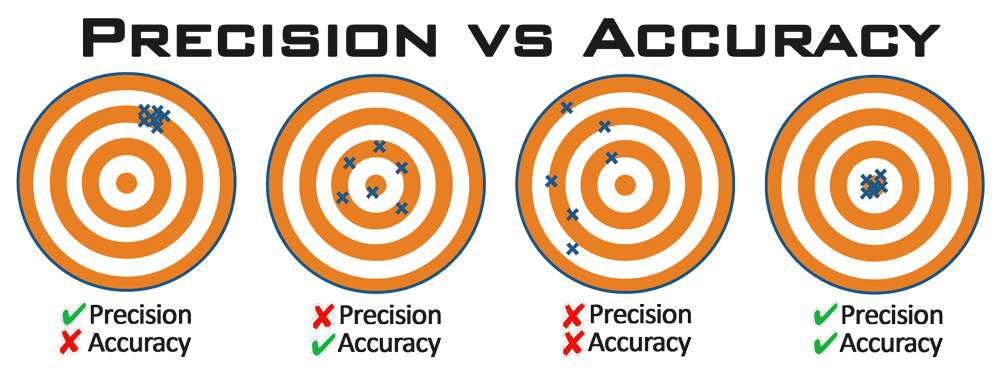

An MSA can identify data that is not true to value or has system errors. These measurement system errors are identified by MSA. They can be classified according to precision and accuracy.

- Precision: The closeness of the sample points to one another.

- Accuracy – The closeness of the sample data points towards the target value.

Why Perform a Measurement System Analysis (MSA)?

A well-designed MSA process will help ensure that the data collected is accurate and that data collection is appropriate for the process. A process can save time, labor, and defects by having reliable data.

How it’s done (the MSA)?

Measurement System Analysis MSA refers to a series of experiments and analyses that are used to assess the capability, performance, and uncertainty of a measurement system. It is important to review the data collected and the tools and methods used to record it. We want to determine the source of variation and quantify the effectiveness. It is important to assess the quality of data collected, including location and width variation. Data should be assessed for accuracy, stability, and linearity.

An MSA activity must evaluate the measurement uncertainty for each type or gauge defined in the Process Control Plans. To obtain useful data, each tool must have the right level of discrimination. The process and the tools used (gages or fixtures, instruments, etc.). Operators and definitions are assessed for precision, accuracy, reproducibility, and repeatability.

Variable vs. Attribute Data Classifications

Before we can analyze the data, or the gages or tools, we need to determine what type of data is being collected. Variable data and attribute data are possible. Attribute data can be classified into specific values, while continuous or variable data can have an infinite number of values. Below are more detailed definitions.

The Variable Gage R&R (Repeatability and Reproducibility) Study

To evaluate the uncertainty level within a measurement system, Gage Repeatability and Reproducibility are available for gages and instruments that collect variable (or continuous) data. First, select the gauge that you wish to evaluate. Next, follow these steps:

- Three operators should be chosen who are familiar with the inspection.

- Each operator should measure and record the samples.

- At least 10 random samples from parts that were produced during a regular production run are required

- Each operator can repeat the measurement three times using the same parts.

- Determine the difference between each operator’s averages and ranges for each sample used in the study.

- Determine the average (mean), and range of trial averages for each operator

- Determine repeatability to calculate the equipment variation

- To determine how much variation is introduced by operators, calculate reproducibility

- Determine the percentages of variation in parts and total

The Variable Gage R & R percentage calculated is used to accept or reject the gage. Below are guidelines for making this decision:

- If the Variable Gage R & R score is below 10%, then the measurement system can be accepted.

- The acceptable measurement system can be determined based on the relative importance or other factors of the application. If the Gage R & R falls between 10 and 30%, the Gage R & R is normally considered acceptable.

- If the Variable Gage R & R is greater than 30% the measurement system is producing non-reliable data and must be improved.

Perform a comparison study to determine the repeatability and reproducibility of Variable Gage R & R results. If the repeatability value is higher than the reproducibility value, this could indicate that the gauge was not working properly. It is possible that the gauge needs to be replaced or calibrated. If the reproducibility is high relative to the repeatability, it could indicate that the variation is related to the operator. An operator may require additional training in the correct use of the gauge or a fixture to aid him.

When do you need a Variable Gage R&R Study?

- Immediately after any improvement activities

- Improvements made to the current measurement system resulting from a previous failed Gage R & R

- Introducing a new type of measurement system

- When a different (existing) measurement system is introduced

- Verifying the measurement system after a scheduled Calibration for the gage

Attribute Gage R&R (often called Attribute Agreement Analysis)

A similar method can be used to analyze attribute measurement systems. This method is normally used to test an inspector’s understanding of a defect/non-defect. The method below will be used to determine the uncertainty in the measurement of an attribute gage:

- Find the attribute gage that will be studied (this in most cases will be someone’s eyes as the product or service will be measured visually)

- Get ten random samples of the product or transaction

- Choose at least two (three or more is better) different inspectors who are familiar with the inspection activity.

- The operators should inspect each sample part at least twice and keep track of the data.

- Next, calculate your kappa value.

- The gauge is acceptable if the kappa value exceeds 0.6

The Attribute gauge study should be based on the same criteria as the Variable Gage R & R Study.

The Gage R&R, or attribute gauge study, should be performed during an MSA on all gages, instruments, or fixtures that are used in the measurement system. For future reference, the results must be recorded and kept in a database. If there are any problems, you can run a new study on the gauge. The results can then be compared with the data from the previous studies to determine if there has been a change. A well-executed MSA can make a dramatic difference in the quality of data collected and product quality.

Why is MSA important?

Poor measurement systems can lead to inferior-quality components falling through the cracks, and high-quality parts being rejected. Customers become unhappy with the inability of manufacturers to meet their quality standards. Manufacturers can conduct an MSA to ensure that the measurement equipment and its operation meet their precision and accuracy standards.