Implementing Lean is a significant commitment that requires ongoing effort. There is no endpoint; instead, Lean becomes a way of life within the organization. Companies must continually assess their processes, seeking new ways to improve and adapt.

It is not just a set of tools or techniques; it is a holistic approach that changes an organisation’s operations. It empowers businesses to thrive in competitive environments by prioritising value creation and waste elimination. Organizations that embrace Lean can improve production, enhance market share, streamline product introduction, and maintain high standards of quality and efficiency.

Table of contents

What is Lean?

Lean is a methodology focused on continuous improvement, with the primary goal of maximizing value for customers while minimizing waste. It emphasizes a systematic approach to identifying and eliminating non-value-added activities in processes, ultimately leading to shorter cycle times and increased efficiency. Contrary to misconceptions, Lean is not about eliminating jobs; rather, it aims to enhance productivity and create a more efficient work environment.

Key Concepts of Lean Management

Lean management transforms how human activities are organized to enhance benefits for society and value for individuals. It involves:

- Creating Value: Lean prioritizes customer value, ensuring that every action taken contributes directly to fulfilling customer needs.

- Continuous Improvement: Lean is about making incremental changes to processes to enhance efficiency and quality over time.

- Cultural Change: Implementing Lean involves a shift in organizational culture, emphasizing teamwork and employee engagement.

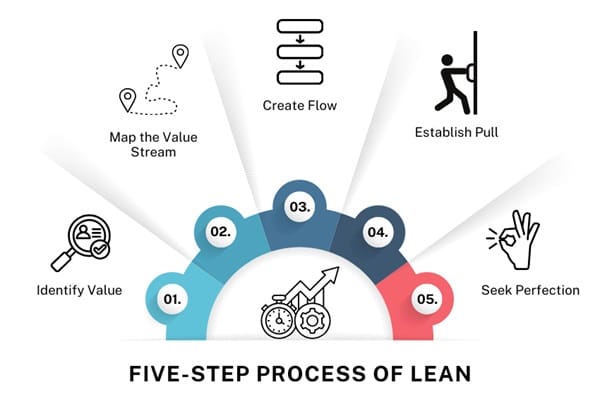

Five-Step Process

Lean implementation is guided by a structured five-step process designed to transform how a business generates revenue. This process helps organizations systematically identify and eliminate waste while enhancing value creation.

- Identify Value: Value is defined by what customers are willing to pay for a product or service. It’s crucial to distinguish between value-adding activities and those that do not add value. Lean identifies several forms of waste—such as defects, overproduction, waiting, unnecessary processing, transportation, excess inventory, and inefficient movement—that must be eliminated. For example, customers do not want to pay for unnecessary handling of inventory or the costs of reworking defective products. Typically, only a small fraction of time in production (less than 5%) is spent on value-adding activities.

- Map the Value Stream: The value stream encompasses all actions required to bring a product from concept to launch, and from order to delivery. Mapping the value stream involves creating a visual representation that includes both value-creating and non-value-creating steps.

- Create Flow: Flow refers to the smooth movement of materials and information throughout the production process. To create effective flow, organizations should reduce distances that materials travel, simplify processes, and increase the speed (velocity) of information and materials moving through the system. Eliminating bottlenecks—where materials or information get stuck—enhances overall efficiency and responsiveness.

- Establish Pull: Unlike traditional methods that focus on optimizing each step in isolation, Lean recognizes the importance of synchronizing operations. A pull system ensures that production is based on actual customer demand rather than forecasts.

- Seek Perfection: Lean is a journey toward continuous improvement. Perfection is the ideal state where processes run smoothly, waste is eliminated, and value is maximized. Achieving perfection is an ongoing pursuit, as there will always be opportunities for further enhancement.

Four Main Focus Points

Successful Lean implementation hinges on four critical focus areas:

1. Effective Leadership

Leadership plays a vital role in establishing a Lean culture. Leaders must communicate a clear vision for the Lean initiative, build trust among employees, and provide guidance through process changes. Effective leaders inspire teams to embrace Lean principles and actively participate in improvement efforts.

2. Teamwork Environment

Creating a collaborative work environment is essential for Lean success. A strong teamwork culture allows employees to share ideas and contribute to organizational success. Valuing diversity and empowering skilled workers to take ownership of their roles fosters accountability and continuous development.

3. Communication Channels

Open communication is crucial for effective Lean implementation. Clear channels between management, shop floor workers, and office staff facilitate the exchange of knowledge and insights. This communication identifies issues, develops new processes, and executes changes smoothly, keeping everyone informed and engaged.

4. Continuous Improvement of Company Processes

Continuous improvement is the backbone of Lean. Organizations must focus on refining their processes consistently, from management strategies to daily operations. This commitment trains employees, learns from suppliers and customers, and ensures that products are designed and built correctly from the start. The aim is to eliminate waste and enhance the entire supply chain.

Core Principles

- Eliminating Waste: Lean categorizes waste into several forms, which can include:

- Defects: Products or services that do not meet quality standards, requiring rework or scrapping.

- Overproduction: Producing more than is needed, leading to excess inventory.

- Waiting: Time spent waiting for the next step in a process, leading to delays.

- Non-Utilized Talent: Not leveraging employees’ skills and knowledge effectively.

- Excess Motion: Unnecessary movements by employees that do not add value.

- Transportation: Unneeded movement of products or materials that can lead to damage or inefficiency.

- Inventory: Holding more stock than necessary, tying up resources.

- Customer Focus: It is deeply rooted in understanding customer needs. It seeks to provide products or services that meet those needs in the most efficient manner. This includes delivering the right product at the right time and at the best possible price.

- Continuous Improvement (Kaizen): It promotes a culture of ongoing improvement. Employees at all levels are encouraged to identify problems and suggest solutions, fostering a sense of ownership and engagement in the process.

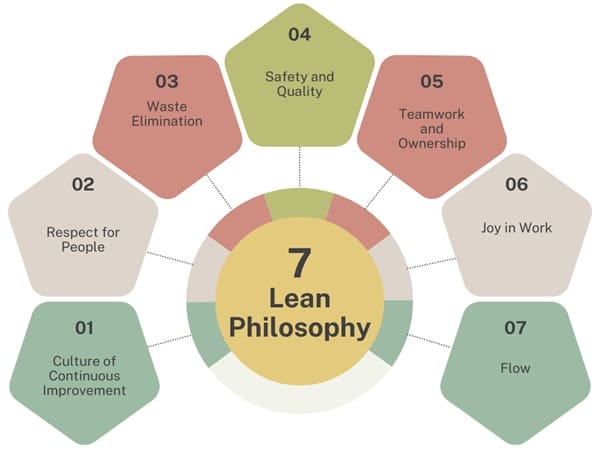

Philosophy

Lean philosophy embodies several principles that guide its implementation:

- Culture of Continuous Improvement: It promotes a mindset of ongoing enhancement at every organizational level.

- Respect for People: It values the insights of employees who are closest to the work, recognizing them as experts in their processes.

- Waste Elimination: It distinguishes between value-adding work and non-value-adding work, focusing on removing waste.

- Safety and Quality: It emphasizes a safe work environment that assures quality for both customers and employees.

- Teamwork and Ownership: It encourages collaboration across departments, fostering a sense of shared responsibility.

- Joy in Work: It seeks to create a fulfilling work environment, recognizing that engaged employees contribute to better outcomes.

- Flow: It aims for uninterrupted processes that move smoothly from start to finish, enhancing efficiency.

Benefits

Organizations that implement Lean can experience several significant benefits:

- Reduced Inventory Costs: By adopting Just-In-Time (JIT) principles, companies minimize the amount of stock they hold, lowering storage costs and reducing waste.

- Shorter Lead Times: Streamlined processes lead to faster response times, allowing businesses to meet customer demands more quickly.

- Improved Quality: Focus on reducing defects enhances product quality, leading to greater customer satisfaction.

- Increased Productivity: Eliminating waste allows employees to focus on value-adding activities, increasing overall productivity.

- Employee Engagement: Involving employees in the improvement process can boost morale and create a more collaborative workplace culture.

Examples of Lean Projects

To illustrate the practical application of Lean, here are some common projects organizations undertake:

- Inventory Reduction: Companies implement systems to track inventory more accurately, reducing overstock and improving cash flow.

- Space Optimization: Reducing the physical space used in production areas can lead to cost savings and a more organized workflow.

- Faster Response Times: Streamlining communication and decision-making processes can significantly cut down on the time it takes to respond to customer inquiries or production changes.

- Quality Improvement Initiatives: Using techniques such as Six Sigma, organizations work to decrease defects and improve product reliability.

- Value Stream Mapping: This tool helps teams visualize the flow of materials and information, identifying bottlenecks and areas for improvement.

Origin

“Lean manufacturing” became popular in the 1980s and comes from the Toyota Production System (TPS). Toyota created TPS to make production more efficient and reduce waste, based on ideas from Henry Ford’s early manufacturing methods. Ford’s Just-In-Time approach aimed to produce only what was needed, cutting down on waste.

What is Lean Thinking?

Lean thinking is a business methodology designed to improve how organizations operate. At its core, it focuses on delivering more value to customers while minimizing waste. The goal is simple: eliminate waste to create value. Lean thinking encourages continuous improvement and emphasizes the importance of involving everyone in the organization in this process.

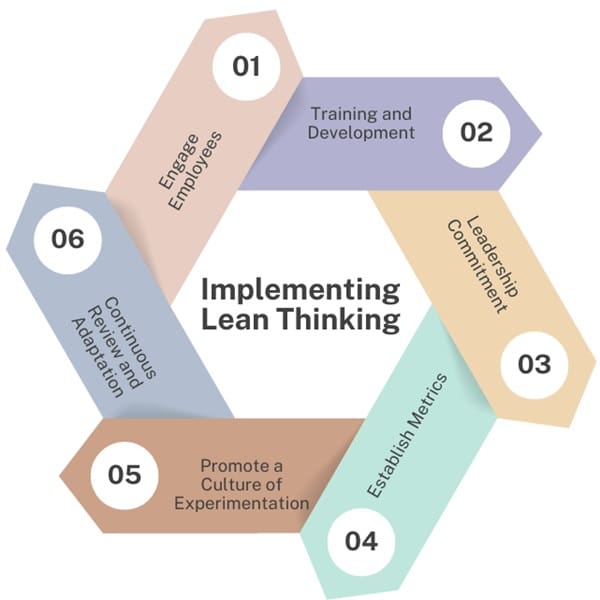

Implementing Lean Thinking

Implementing Lean requires a strategic approach that engages everyone in the organization. Here are some key steps:

- Engage Employees: Encourage all team members to participate in identifying waste and suggesting improvements. Their insights are invaluable in recognizing inefficiencies.

- Training and Development: Equip employees with the necessary tools and knowledge to understand Lean principles and practices. Ongoing education fosters a culture of continuous improvement.

- Leadership Commitment: Successful Lean implementation relies on support from leadership. Leaders must model Lean behaviors and allocate resources for improvement efforts.

- Establish Metrics: Track progress by defining metrics that measure performance, such as lead times, defect rates, and employee engagement. Regularly review these metrics to gauge success and areas for further improvement.

- Promote a Culture of Experimentation: Lean encourages experimentation to test new ideas and processes. This scientific approach to problem-solving allows organizations to learn from failures and successes.

- Continuous Review and Adaptation: Lean is not a one-time effort but an ongoing journey. Regularly assess processes and solicit feedback to identify new opportunities for improvement.

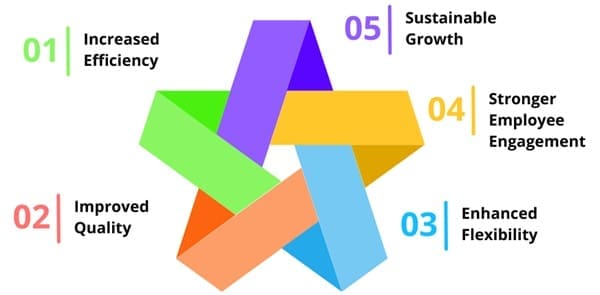

Benefits of Lean Thinking

Organizations that embrace Lean thinking can experience a range of benefits:

- Increased Efficiency: By eliminating waste and optimizing processes, organizations can operate more efficiently, reducing costs and time.

- Improved Quality: Focus on continuous improvement leads to higher quality products and services, resulting in increased customer satisfaction.

- Enhanced Flexibility: Lean practices allow organizations to respond more quickly to changes in customer demand or market conditions.

- Stronger Employee Engagement: Involving employees in improvement processes fosters a sense of ownership and commitment to the organization’s success.

- Sustainable Growth: It encourages long-term thinking and continuous improvement, positioning organizations for sustainable success.

Key Texts Influencing Lean Thinking

Two influential books have shaped Lean philosophy:

- “The Machine That Changed the World” (1990): This book by James Womack, Daniel Jones, and Daniel Roos discusses the principles of Lean and the success of the Toyota Production System.

- “Lean Thinking” (1996): Written by Womack and Jones, this book further explores Lean principles and provides a framework for implementing Lean in various industries.

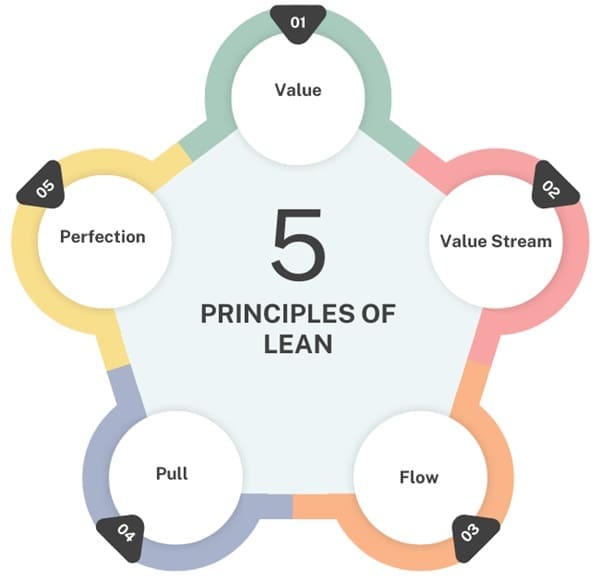

Five Principles of Lean

- Value: Value is defined from the customer’s perspective. To determine value, organizations must ask:

- Would the customer pay for this activity?

- Does this activity improve or transform the product?

- Is the task completed correctly the first time?

- Value Stream: This involves mapping out all steps in the process to identify which activities add value and which do not. The goal is to streamline operations by eliminating non-value-added tasks.

- Flow: It aims to create a smooth flow of work with minimal interruptions. Continuous flow reduces wait times and improves efficiency.

- Pull: Instead of pushing products through the process based on forecasts, Lean emphasizes producing only what is needed when it is needed. This reduces overproduction and inventory costs.

- Perfection: It advocates for a relentless pursuit of improvement. Organizations should strive to continually refine processes and eliminate waste.

Lean Tools and Techniques

Several tools and techniques can facilitate the implementation of Lean:

- 5S Methodology: This technique focuses on organizing the workplace to enhance efficiency. The five stages are Sort, Set in order, Shine, Standardize, and Sustain.

- Kaizen: This is a continuous improvement approach that encourages small, incremental changes. Kaizen events often involve teams working together to solve specific problems.

- Root Cause Analysis: This problem-solving technique helps teams identify the underlying causes of issues, allowing for effective solutions rather than quick fixes.

- Value Stream Mapping (VSM): A critical tool for visualizing processes, VSM helps organizations identify waste and opportunities for improvement. It maps the flow of materials and information from suppliers to customers.

Implementing Lean in Practice

- Engaging Employees: Successful Lean initiatives require the involvement of everyone in the organization. Employees should be encouraged to participate in identifying issues and suggesting improvements.

- Training and Development: Providing training on Lean principles and tools is essential. Employees need the skills and knowledge to contribute effectively to Lean initiatives.

- Leadership Support: Leadership must be committed to Lean principles and support employees in their efforts to implement changes. This includes allocating resources and providing time for improvement activities.

- Monitoring and Measuring Progress: Organizations should establish metrics to track the effectiveness of Lean initiatives. This can include measuring lead times, defect rates, and employee engagement levels.

Final Words

Lean is a transformative approach that can significantly enhance an organization’s efficiency, quality, and customer satisfaction. By focusing on waste elimination, understanding customer value, and fostering a culture of continuous improvement, businesses can achieve remarkable results.

The journey toward Lean is ongoing, but the benefits—ranging from reduced costs to increased employee engagement—make it a worthwhile endeavor for any organization. Embracing Lean principles not only improves operations but also creates a more dynamic and responsive business environment.

How to Become a Lean Practitioner?

Six Sigma Development Solutions, Inc. has an excellent LEAN Certification Course. We are an Accredited Training Organization (ATO) with the International Association of Six Sigma Certification (IASSC). The certification course can be held either virtually, on-site (at your organization) or a hybrid of both. We also have virtual, live in-person, and hybrid public courses held monthly at our 50+ global training sites.

The course is full of games, videos, and simulations. We will be playing with dice, legos, and airplanes to make the LEAN Methodologies come to life. The instructors will keep you engaged and excited!

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.