Description

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. is Certified is an Accredited Training Organization with the International Association of Six Sigma Certification (IASSC). “The IASSC Accredited Training Organization (ATO) designation validates Six Sigma Development Solutions, Inc. has demonstrated adequate management systems, courseware with a high degree of correlation to the subject matter contained in the IASSC Bodies of Knowledge, delivery schema consistent with such content and highly qualified instructors.”

About the course:

The Lean Six Sigma Input Mapping Online Training video is 60 minutes in length. After the video, as an assignment, you will be asked to complete the Critical Elements of the Input Map.

You can download the Lean Six Sigma SIPOC Diagram template at https://sixsigmadsi.com/product/six-sigma-root-cause-analysis-templates.

There will be a quiz at the end of the module. Once the Course is completed and the exam is passed, you will be immediately awarded a Certificate of Completion

The Core equation in Six Sigma is Y=f(X1, X2, X3, Xn). In order to understand our “Y” or Output, we must first define our “X’s” or Inputs. The Input Map (or Variables Map) is a tool used to define those Inputs.

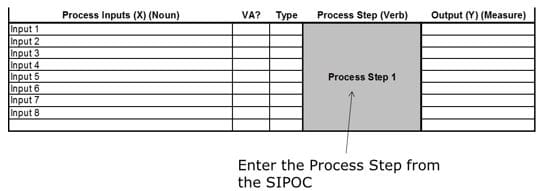

Step #1: Enter the Process Steps. These steps should come the “P” (Process) in your SIPOC.

- There should be no more than 12 steps

- If there are more than 12 steps, you should review your project scope because it may too large

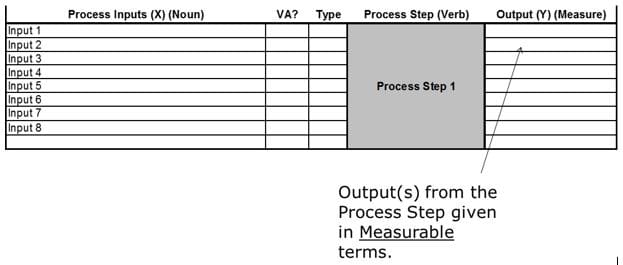

Step #2: List the Process Measurable Outputs.

- These are the Measurable Outputs from the Process Step

- The Outputs are related with the Steps not the Inputs. In other word, I can have 20 inputs in the “Input” column with 3 outputs in the “Output” column

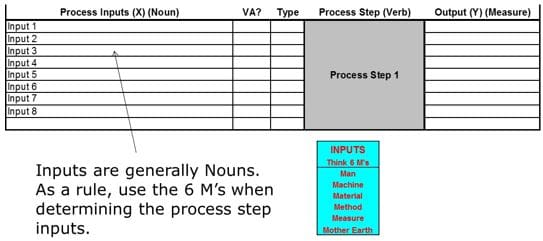

Step #3: Enter the Process Inputs.

- As a general rule, the Input should be no more than a 3 word Noun (not an Adverb or Adjective)

- Go to Gemba, Walk the Process and take notes of all Inputs to the Process. Don’t determine that an Input is Insignificant and not write in on the Input Map, we will use a tool called the C&E Matrix to sift out the Unimportant “Inputs”.

Step #4: List the “Type” of Variable as “U” (Uncontrollable) or “C” (Controllable).

- Controllable (C): Inputs that you can adjust while the process is in action

- Example: While in the process of mowing a lawn, you can adjust the height of the mower or the speed at which you push the mower

- Uncontrollable (U): These are Inputs that you either can’t control or are unwilling to control (because of cost, company politics, etc.)

- While mowing a lawn, you cannot control the weather as it can change from sunny to raining.

To learn more, register for our Input Map Online Training.

Reviews

There are no reviews yet.