Mura is a term used in the Toyota Production System to describe unevenness in production. TPS identifies it as one of three waste types, along with muda (waste), and muri (overburden).

Three types of wasteful activities, muda, mura, and muri, negatively affect workflow, productivity, and customer satisfaction. These terms, which are Japanese, play a key role in the Toyota Way.

This is a management philosophy that was developed by Taiichi Ahno to create automobiles on demand following World War II. Lean software development is based on the Toyota Way and uses the labels muda, mura and muri.

By recognizing the three types of inefficiency, you can avoid wasting time, resources, products and human effort.

Table of contents

What is Mura?

Mura is one form of waste that the Toyota Production System identifies as “3M”. The other two are muda and muri. In Japanese, “mura” means variability, unevenness, or inconsistency.

Mura often shows up as an inconsistent pace of work, where your team goes from being overloaded with tasks to having idle time on their hands. In Lean, mura can be divided into two categories: Inconsistent teamwork

Inconsistent customer demands.

When trying to improve a process, both of these factors need to be taken into consideration.

Reducing process variability is important in achieving Lean Management’s primary objectives: delivering maximum value to customers while minimizing waste and non-value-adding activities.

Mura coexists with other waste components

Public, Onsite, Virtual, and Online Six Sigma Certification Training!

- We are accredited by the IASSC.

- Live Public Training at 52 Sites.

- Live Virtual Training.

- Onsite Training (at your organization).

- Interactive Online (self-paced) training,

Muri

Overburdening, excessiveness, e.g. Overloading a machine or the capacity of a machine operator to an unachievable level. Mura, or an excess of Muda can cause a person to work beyond their capacity. Overworked people and equipment are more likely to fail. Overworked workers can lead to reduced productivity, absenteeism, and turnover.

Muda

Muda is wastefulness, futility and inefficiency, which are opposites to value-addition. Value-added is work that adds to the value of a product or service the customer will pay for.

The work that doesn’t add value can be divided into two categories – work that is needed but isn’t recognized as such by the customer, and work that is simply not necessary.

Type 1 and Type 2 are the two types of Muda. Muda Type 1 is a collection of non-value-added activities that are required for the customer. Inspection and safety testing, for example, do not add direct value to the end product. They are still necessary to provide a safe product to customers. Muda Type 2 involves non-value-added processes. However, these activities are not necessary for the customers. Muda Type 2 is therefore to be eliminated.

The abbreviation for Muda Type 2 is TIMWOOD. Transport, i.e. The seven wastes are

- Transport

- Inventory (i.e. Stocks of raw materials and goods)

- Motion (i.e. Excessive movement of machines or people)

- Waiting

- Overproduction

- Over-processing

- Defects

Also Read: Makigami

Why is unevenness in the process bad?

Standardization and optimization are the first steps in any Lean/Six Sigma improvement effort. Since variability can lead to defects and a drop in quality – which directly impacts the value delivered to customers.

Reasons for uneven processes

- Different team members may work differently

- Machines can have a variety of outputs and operations

- How a team collects data and reports results varies from person to person.

A Six Sigma-optimized process is defined as one that has a reduced variability to the point that the expected output can only be achieved 3.4 times in 1000000 executions. Six Sigma’s main selling point is its ability to meet customer expectations at a high success rate (quasi-zero defects).

Muda Mura and Muri Together

Muda, Mura, and Muri, are often used in conjunction with each other to describe wasteful behaviors that need to be eliminated.

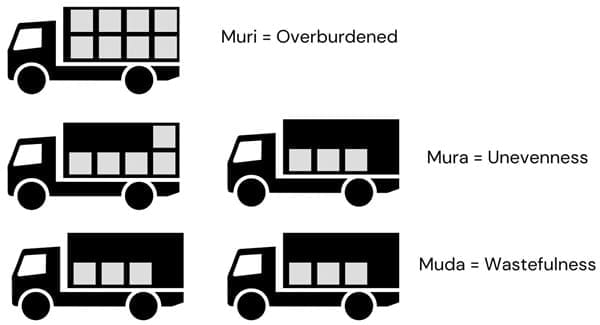

Simple illustration of how muri, muda and muda are often related so that eliminating any one eliminates all the others.

Imagine that a company needs to deliver eight tons of materials to a customer. It is weighing its options. The first option is to load all eight tons onto one truck and do a single journey. This would be muri, as it would overload the truck (rated at only three tons), leading to breakdowns and muda.

The second option would be to make two trips. One with five tons, and the other three. This would cause mura, because uneven materials arriving at the client would lead to jams on the dock and too little work. This option would also create muri because, on one trip, the truck is still overloaded, and muda because, due to the uneven pace of the work, the receiving employees would waste time waiting.

Thirdly, you can load the truck with three tons and make three trips. This would still be muda even if it wasn’t mura or muri because the truck was only partially loaded each time.

Only by loading the truck to its rated capacity of four tons and making two trips can you eliminate muda and mura.

Benefits of Mura Reduction

Mura reduction improves efficiency by minimizing irregularities in production processes. This results in improved resource utilization, decreased idle time and an overall increase in operational efficiency. With a streamlined workflow, companies can increase productivity and better meet customer needs.

Mura reduction leads to improved product reliability and quality. Reduced variations and defects on the production line can help organizations deliver products that meet or exceed customers’ expectations. A higher-quality product not only increases customer satisfaction but also improves an organization’s market reputation.

- Cost Savings: Mura reduction initiatives can lead to savings in various areas of operation. Organizations can reduce operational costs and increase profitability by eliminating waste, minimizing surplus inventory, and decreasing lead times.

- Flexibility and Agility: Reduced Mura allows for greater flexibility and agility in response to changes in the market or operational conditions. Smoother workflows, standardized processes and supply chain disruptions can be quickly adapted by organisations with a standardization of their processes.

- Employee Empowerment: Mura reduction initiatives empower employees by giving them clear, standardized procedures and reducing the variability of their work environment. Employees can concentrate on problem-solving and innovation when they have a consistent workflow and optimal resource allocation.

- Customer Satisfaction: The benefits of Mura reduction ultimately lead to improved customer satisfaction. Consistent quality, shorter lead time, and reliable schedules improve the customer experience. Organizations can increase brand loyalty and trust by consistently exceeding customer expectations.

Also Read: What is Heijunka

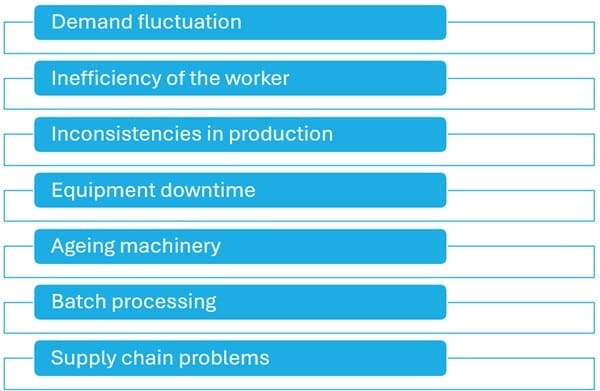

Causes and Effects of Mura

- Demand fluctuation: Uneven workflows and bottlenecks can occur in production lines due to fluctuations in customer orders.

- Inefficiency of the worker: Variable skill levels, irregular work pace and frequent errors contribute to irregularities in output rates and cycle times.

- Inconsistencies in production: Unevenness in production is often worsened by the absence of standardized procedures and inadequate cross-training practices.

- Equipment downtime: Unplanned or planned breakdowns can disrupt uniform production, leading to an overproduction as a result.

- Ageing machinery: Requiring more frequent maintenance can cause unevenness.

- Batch processing: The production of large lots hinders the production of uniform volumes and pace.

- Supply chain problems: Delays in deliveries or poor quality materials can disrupt operations and cause mura.

Identification of Mura

Mura (also known as unevenness) can appear in many different forms during manufacturing processes or operations. It’s important to measure and identify mura to effectively tackle the root causes. These are some of the most common ways to do so:

- Visual Observation: Careful observation can reveal irregularities such as cycle times, operator movement, material handling or quality issues. Gemba walks are a common way for experienced lean practitioners to identify mura. They observe the work first-hand and can then make logical conclusions.

- Process Cycle Time Analyses: You can identify variations and fluctuations by measuring and analysing the cycle times of different workstations and operators. Techniques such as cycle time charts and histograms can help pinpoint irregularities.

- Work in Process Monitoring (WIP): Tracking the WIP levels can reveal bottlenecks or starving processes.

- Quality Data Analysis: Analyzing defect rates, rework level, and customer complaints, can reveal unevenness in the quality of products, which is often due to underlying process variations.

Also See: Lean Six Sigma Certification Programs, Fresno, California

Measuring the Impact of Mura

- Takt Time Adherence (Takt Time Adherence): Measuring deviations from the required takt times (pace of manufacturing based on the customer’s demand) across products or processes.

- Cycle Time Variation: Calculation of the range, standard deviation or other statistical measures for cycle time variations in a particular process. Calculate the difference in workload between operators or workstations.

- Overall Equipment Effectiveness: This is a measure of losses caused by unplanned downtimes, speed issues, and poor quality. All these factors are influenced in part by mura.

- Value Stream Mapping: By creating a visual representation, you can identify areas where material flow and information flow are uneven.

Strategies to Reduce Mura

To reduce mura, or unevenness, in production processes, you need a systematic approach as well as a commitment to continuous improvements. Here are some strategies for reducing mura.

- Implement Heijunka (Production Leveling): Heijunka aims to smooth out production volume and mix over a set period of time. This approach promotes a consistent workflow, reducing the strain on resources while minimizing irregularities. Using methods such as mixed model scheduling and sequencing helps in achieving Heijunka.

- Establishing a pull system: We align production with customer demand in real-time by adopting a pull system, such as the Kanban method exemplified. This strategy reduces overproduction as well as underproduction – the two main sources of mura.

- Enhancing Workflow and Layout: We can identify and eliminate irregularities by analyzing and improving the workflow and layout of production processes. Some tactics that can facilitate smooth information and material flows include reorganizing workstations, adopting cellular production, and integrating storage at the point of use.

- Standardizing Work Processes: Standardizing work processes through tools such as standardized work instructions, visual cues and other standard work procedures promotes uniformity in operations. This standardization reduces mura by reducing variations in cycle time, output and quality.

- Cross-Training Employees: By allowing employees to perform multiple tasks and operate different machines, you can balance the workload. This versatility allows for optimal resource allocation and a constant production pace.

- Fostering Continuous Improvement (Kaizen): Developing a culture that encourages continuous improvement continually identifies and eliminates mura. Kaizen events and employee involvement are two ways to do this. Regular analysis and improvement efforts maintain a uniform and seamless production flow.

Final Words

Mura, or unevenness in production poses significant challenges for operational efficiency and customer service. Mura is often a cause of wasted resources, inconsistent quality and higher costs.

Businesses can reduce mura by implementing standard procedures, retraining employees and cultivating a culture of continual improvement. It not only improves the adaptability of production processes, but also increases responsiveness and flexibility to customer needs.

Reduced mura promotes an improved workflow, increases resource utilization and improves organizational performance. This allows companies to achieve sustained success within today’s competitive environment.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.