Table of contents

What is TAKT time?

Organizations are always looking for ways to decrease wasted time and resources while providing more attractive products to customers. This is LEAN thinking. The meaning of TAKT time is a metric used in the LEAN methodology to measure the FLOW of the process. It is implemented in a business to help reduce waste and create a smooth workflow that is delegated by the PULL of customer demand. TAKT time is a vital tool for ensuring that products and services move through the process efficiently.

TAKT is German for “beat” (like the rhythmic beat of a song), or it can be also translated to mean “measure”. In LEAN we use the word TAKT to mean the measured pace (or beat) of the process. TAKT time works more optimally when the workflow is repetitive, or customer demand is predictable.

TAKT time formula

TAKT time lean is often incorrectly defined as overall build time (or the amount of work required to build a service or product). But it refers to the time required to build a single service or product (from start to finish) to meet customer demand (in other words, to not produce a product in the prediction of demand).

The TAKT time formula is “Available time to produce the product or service” divided by “Customer demand”.

Let’s break TAKT time down:

Available time to produce the product or service

For example, a manufacturer works an 8-hour shift, five days a week. 8 hours x 60 mins equal 480 total minutes. However, not all 480 minutes are available. The “available” time is reduced by breaks, and clean-up at the end of each shift. Assuming that there are two 10-minute breaks, a 30-minute lunch break, and 20 minutes total at the end and beginning of each day, then the “available” production time would be 410 minutes.

Customer demand

The number of products or services that the customer needs during a range of time (usually a day or shift). Let’s say that an order entry process transacts 100 orders per day.

TAKT time

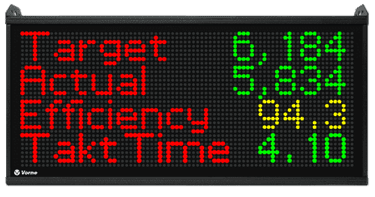

If we take our available time to produce (410 minutes) and divide it by the customer demand (100 orders processed), then the TAKT times equal 4.1 minutes or 246 seconds per order. If the order entry process is capable of meeting customer demand, an order must be processed every 246 seconds.

Importance and benefits

TAKT time allows organizations to understand their capacities. Businesses can calculate the speed of equipment and staffing needed to produce at a consistent pace to meet customer demand.

This will result in a greater flow of efficiency and less waste of time and resources.

It helps companies see their achievements over a specific range of time. It also allows companies to spot disruptions and constraints in production processes. The team can respond quickly if a visual signal like a TAKT time board tells them that the process is not producing to the TAKT time.

In conclusion

TAKT time refers to the amount of time it takes to produce a product to meet customer demand. Businesses can use this tool to create a continuous workflow. It allows organizations to better understand their capacity, their constraints, and reduce waste. Teams can quickly see their success and react to disruptions. Companies can incorporate this methodology into their products and services to help serve their customers more efficiently with better quality.