Continuous improvement (CI) is a systematic approach aimed at enhancing the quality and efficiency of services and products delivered to customers.

This method focuses on refining work methods, procedures, and systems while reducing costs, ultimately leading to improved outcomes for organizations.

Continuous improvement can be seen as a philosophy that encourages a culture of ongoing learning and adaptation, making it essential for organizations seeking to remain competitive in an ever-changing environment.

Table of contents

- Definition and Key Concepts of Continuous Improvement

- What is Continuous Improvement?

- Principles of Continuous Process Improvement

- 1. Define How Work is Being Done

- 2. Understand Your Problem & Define Your Outcome

- 3. Connect Your Process Improvement Initiatives to Business Objectives

- 4. Make Process Improvement Customer-Centric

- 5. Involve Subject Matter Experts & Process Owners

- 6. Empower Employees and Use Their Ideas

- 7. Focus on Incremental Improvements Over Mass Change

- 8. Continuous Process Improvement is Never-Ending

- 9. Measure, Monitor, Repeat

- Evolution of Continuous Improvement

- Proficiency Levels in Continuous Improvement

- Knowledge Management and Continuous Improvement

- Process of Continuous Improvement

- Implementing Continuous Improvement in Your Organization

- Final Words

- Related Articles

Definition and Key Concepts of Continuous Improvement

At its core, continuous improvement is about measuring, upgrading, and refining processes to enhance performance. It emphasizes the following key areas:

- Work Method Improvement: This involves analyzing and optimizing existing work practices to increase efficiency and effectiveness.

- Cost Efficiency: Aiming to reduce operational costs while maintaining or enhancing quality is crucial for organizational sustainability.

- Productivity: Continuous improvement seeks to boost overall productivity by streamlining processes and eliminating waste.

What is Continuous Improvement?

Continuous Improvement (CI) is a management philosophy that emphasizes ongoing, incremental enhancements in processes, products, and services. Rooted in the belief that no process is ever perfect, CI advocates for regularly re-evaluating and refining workflows to foster efficiency and effectiveness.

This document explores the principles of continuous process improvement, discusses its relevance across industries, and explains how organizations can effectively implement it to achieve their goals.

Benefits of Continuous Improvement

The implementation of continuous improvement processes offers several key benefits:

- Enhanced Collaboration: CI encourages teamwork and collaboration among stakeholders, fostering a culture of shared responsibility and collective learning.

- Data-Driven Decision Making: Continuous improvement emphasizes the importance of data collection and analysis, enabling organizations to make informed decisions based on evidence rather than assumptions.

- Adaptability: The iterative nature of continuous improvement allows organizations to remain flexible and responsive to changing conditions and emerging challenges.

- Sustainable Change: Focusing on small, manageable changes promotes sustainability and resilience through continuous improvement, ensuring that you can maintain these improvements over the long term.

Challenges in Implementing Continuous Improvement

While continuous improvement offers many advantages, organizations may face challenges in its implementation. Common obstacles include:

- Resistance to Change: Individuals and teams may be resistant to altering established practices, particularly if they perceive changes as threatening or unnecessary.

- Insufficient Training and Support: Implementing CI requires adequate training and resources to ensure that stakeholders are equipped with the skills and knowledge necessary to engage in the process effectively.

- Inadequate Data Collection: Without a robust data collection strategy, it can be challenging to assess the impact of change practices and refine them effectively.

Methodology for Continuous Improvement

A structured methodology for implementing continuous improvement can help organizations effectively capitalize on knowledge and improve processes. This approach typically involves the following steps:

- Framing the Knowledge Capitalization Project: Establishing clear objectives and scope is essential for guiding the continuous improvement process.

- Identifying Expert Profiles: Selecting diverse experts from various organizations helps incorporate different perspectives and practices.

- Conducting Interviews: Gathering insights through interviews allows organizations to understand best practices and challenges in the field.

- Knowledge Modeling: Utilizing models to clarify the continuous improvement process enables organizations to visualize goals, missions, subprocesses, and activities.

- Validation and Feedback: Engaging experts in validating and providing feedback on models ensures accuracy and enhances their effectiveness.

Building a Culture of Continuous Improvement

Creating a culture of continuous improvement requires commitment from all levels of the organization. Key principles to guide this process include:

- Problem Identification: Clearly defining the problems that require attention is essential for setting focused improvement goals.

- Testing Changes: Implementing and testing innovations is at the heart of continuous improvement, allowing organizations to evaluate the effectiveness of changes.

- Measuring Impact: Establishing clear performance measures to assess whether changes result in meaningful improvements is critical for sustaining momentum.

Principles of Continuous Process Improvement

1. Define How Work is Being Done

Before embarking on any improvement journey, it is essential to understand and document existing workflows. Mapping out how work is currently performed provides a baseline for identifying areas needing enhancement.

This process of visualization enables organizations to pinpoint inefficiencies, redundancies, and bottlenecks within their operations. Without a clear picture of the current state, efforts to improve processes may be misguided or ineffective.

2. Understand Your Problem & Define Your Outcome

Identifying the problems within a given process is crucial for successful improvement initiatives. Organizations must clarify their desired outcomes and understand the specific challenges they face. This involves setting clear, measurable goals for what the improvement efforts aim to achieve.

By defining these objectives, organizations can drive their initiatives more effectively and ensure that the changes made address the core issues.

3. Connect Your Process Improvement Initiatives to Business Objectives

For continuous process improvement to be truly impactful, it should align with the broader business goals of the organization. This might include objectives such as cost reduction, enhanced efficiency, or digital transformation.

Establishing this connection not only justifies the effort put into process improvement but also helps demonstrate tangible results to stakeholders, fostering a culture that values ongoing enhancements.

4. Make Process Improvement Customer-Centric

A customer-centric approach is vital in continuous improvement. Whether the customer is an internal stakeholder or an external consumer, any changes to processes should enhance their experience and meet their needs.

By focusing on customer value, organizations can ensure that their improvement efforts resonate with those they serve and drive satisfaction.

5. Involve Subject Matter Experts & Process Owners

The insights of those who directly execute and own the processes are invaluable in continuous improvement efforts. Their expertise should not only inform the definition of current workflows but also play a critical role in identifying problems and proposing solutions.

Engaging these individuals fosters collaboration and empowers them to take ownership of the changes, which can lead to smoother implementations and reduced resistance.

6. Empower Employees and Use Their Ideas

Encouraging input from employees is essential for fostering a culture of continuous improvement. Those on the front lines often have the best understanding of the challenges within a process.

By actively involving them in problem identification and solution development, organizations can leverage their insights to create meaningful changes. This participation also enhances employee engagement, as they feel their contributions are valued.

7. Focus on Incremental Improvements Over Mass Change

A common misconception about continuous improvement is that it requires sweeping changes. In reality, CI thrives on small, incremental adjustments that gradually enhance processes.

These minor tweaks can lead to significant benefits over time, as opposed to the disruptive effects that large-scale changes might bring. Emphasizing incremental improvements allows organizations to adapt without overwhelming their workforce.

8. Continuous Process Improvement is Never-Ending

Continuous improvement embodies the Kaizen philosophy, emphasizing that the journey of enhancement is ongoing. Once a process has been improved, it should be revisited periodically to assess further opportunities for enhancement.

This commitment to perpetual evaluation and refinement ensures that organizations maintain their momentum toward operational excellence.

9. Measure, Monitor, Repeat

Like any business initiative, organizations must measure and monitor continuous improvement efforts to gauge their effectiveness. They should regularly assess the impact of the incremental changes they implement, scrutinizing the results to ensure they realize the desired benefits.

This cycle of measurement and adjustment is vital to sustaining progress and adapting strategies as necessary.

Evolution of Continuous Improvement

Continuous improvement has its roots in post-World War II Japan, where it became a fundamental philosophy for performance enhancement in manufacturing. Pioneers like W. Edwards Deming and Masaaki Imai contributed to its evolution, emphasizing iterative processes and organizational involvement. As highlighted by various researchers, CI has become increasingly essential for organizations striving to remain competitive and adapt to changing market conditions.

Over the years, CI has transformed into a necessity for organizations, allowing them to enhance performance, maintain competitiveness, and respond to emerging challenges. The approach features iterative cycles of evaluation, learning, and adaptation, fostering a culture of ongoing improvement.

Guiding Principles for Continuous Improvement

To maximize the effectiveness of continuous improvement efforts, certain guiding principles should be upheld:

- Skill Development: Empowering individuals with the skills and knowledge necessary for self-reflection and data-driven decision-making fosters a collaborative learning environment.

- Address Real Issues: Continuous improvement initiatives should focus on genuine problems, providing staff with strategies to build on strengths and seize opportunities.

- Encourage Multiple Perspectives: Involving diverse stakeholders in the improvement process enriches discussions and outcomes, ensuring that various viewpoints are considered.

- Flexibility and Adaptability: Continuous improvement efforts must remain responsive to changing circumstances and contexts, allowing for adjustments as necessary.

- Local Context Sensitivity: The data collected should reflect the realities faced by those affected by the changes, ensuring relevance and efficacy.

Behavioral Indicators of Continuous Improvement

To implement continuous improvement effectively, organizations should focus on several behavioral indicators:

- Identification of Improvement Areas: Recognizing specific areas where work methods can be enhanced is essential. This may involve analyzing workflow bottlenecks or outdated practices that hinder productivity.

- Enhancing Effectiveness: Improving work methods, systems, and equipment effectiveness is key to addressing operational costs and revenue expenditures. Organizations should continually assess and adapt their operations to maximize efficiency.

- Technological Solutions: Leveraging technology can significantly enhance performance. Implementing new software, automation tools, and data analytics can drive improvements across various functions.

- Employee Development: Continuous improvement also focuses on enhancing employee effectiveness through proper training and performance appraisals. Engaging staff in the improvement process is vital for fostering a culture of innovation.

- Utilization of Information Technology: Organizations should leverage IT to improve services, enhance staff productivity, and promote operational efficiency. This includes adopting advanced software and tools to facilitate better communication and data sharing.

Proficiency Levels in Continuous Improvement

Organizations can assess their maturity in continuous improvement through various proficiency levels, which outline specific competencies at each stage:

First Level: Foundational Understanding

- Evaluation of Activities: Organizations must systematically evaluate why similar activities yield different results in varying contexts. This understanding is crucial for pinpointing discrepancies in performance.

- Goal Achievement Analysis: Evaluating why established goals are not met, despite expectations, helps identify systemic issues.

- Mistake Analysis: Understanding the reasons behind recurring mistakes is vital for developing effective solutions.

- Customer Expectations: Facilitating discussions to understand customer expectations and negotiating mutual goals is essential for aligning services with market needs.

- Focus on Results: Emphasizing results over activities ensures a more significant impact on organizational performance.

Second Level: Intermediate Application

- Specialized Knowledge Application: Organizations should apply specialized knowledge to produce work products effectively, ensuring alignment with improvement needs.

- Stakeholder Engagement: Maintaining credibility and facilitating buy-in through effective discussions with stakeholders fosters collaboration.

- Process Improvement Recommendations: Developing and implementing recommendations for process redesigns is critical for achieving operational efficiency.

- Contribution to Knowledge Bases: Sharing best practices and redefining tools helps build a robust knowledge base for continuous improvement.

Third Level: Advanced Implementation

- Organization-wide Solutions: Designing and implementing improvement solutions across the organization to address complex challenges is a hallmark of advanced continuous improvement practices.

- Critical Success Factors: Identifying and addressing factors crucial for the success of improvement initiatives is essential for sustainable growth.

- Commitment from Leadership: Securing commitment from senior personnel enhances the likelihood of successful implementation of improvement projects.

- Subject Matter Expertise: Recognized as experts outside their business units, continuous improvement leaders can provide invaluable insights to project teams.

Knowledge Management and Continuous Improvement

Knowledge management (KM) plays a crucial role in supporting continuous improvement efforts. As organizations seek to innovate and adapt, effective KM mechanisms enable the creation, sharing, and reuse of knowledge. This involves both tacit knowledge (personal insights and experiences) and explicit knowledge (documented information and processes).

Knowledge Creation Process

The knowledge creation process plays a fundamental role in continuous improvement. It can be understood through four modes:

- Socialization: This involves sharing experiences and insights among individuals to foster a collective understanding.

- Externalization: Transforming tacit knowledge into explicit knowledge allows for documentation and dissemination across the organization.

- Combination: Integrating different forms of knowledge to develop new ideas and practices is vital for continuous improvement.

- Internalization: Individuals internalize shared knowledge, enhancing their understanding and contributing to further tacit knowledge generation.

Process of Continuous Improvement

Continuous improvement engages key players in a systematic process to address specific issues. This process typically involves several iterative cycles, including:

- Identifying a Problem: Stakeholders collaboratively define a specific problem of practice that needs to be addressed.

- Testing Change Practices: Teams develop and implement new strategies, tools, or approaches aimed at solving the identified problem.

- Data Collection and Analysis: As changes are made, data is collected to assess their impact. This information is crucial for understanding the effectiveness of the change practices.

- Refining and Scaling Up: Based on the collected evidence, stakeholders can refine the change practices to improve their effectiveness. Successful strategies can then be scaled up to broader applications within the system.

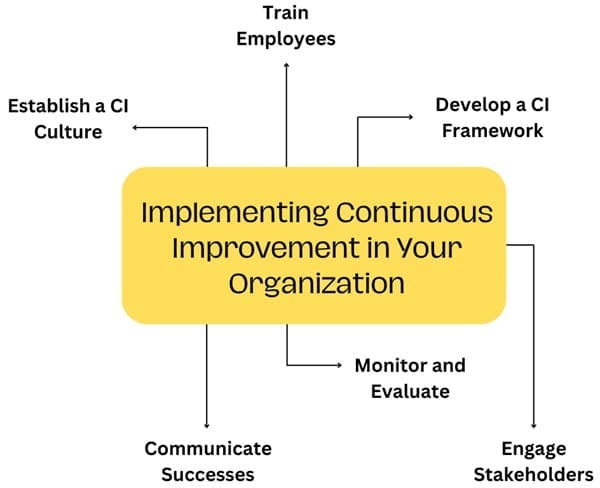

Implementing Continuous Improvement in Your Organization

To successfully implement continuous improvement, organizations should consider the following steps:

- Establish a CI Culture: Leadership must create an environment that encourages experimentation, collaboration, and openness to change. This culture should promote collective responsibility for outcomes and learning from both successes and failures.

- Train Employees: Providing training and resources to employees at all levels ensures that they have the necessary skills and knowledge to engage in continuous improvement efforts effectively.

- Develop a CI Framework: Organizations should establish a structured framework for CI initiatives, including defined processes for identifying problems, setting goals, and measuring progress.

- Engage Stakeholders: Involving a diverse range of stakeholders in the CI process can provide valuable insights and foster buy-in for proposed changes.

- Monitor and Evaluate: Regularly assess the effectiveness of CI initiatives to ensure that desired outcomes are being achieved. This evaluation should inform future efforts and adjustments.

- Communicate Successes: Sharing successes and lessons learned can reinforce the value of continuous improvement efforts and motivate further participation.

Final Words

Continuous improvement is a powerful framework for fostering sustainable change across various sectors, particularly in education and human services.

By embracing the core principles of CI—recognizing that change takes time and collective effort, adapting to specific contexts, and focusing on small changes—organizations can enhance their capacity to solve complex problems and improve outcomes.

Through iterative cycles of testing, learning, and refining, continuous improvement cultivates a culture of collaboration, adaptability, and data-driven decision-making, paving the way for lasting positive impact.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.