Cycle time is a critical metric in manufacturing that measures the time taken to complete a task or a collection of tasks from start to finish.

This concept is fundamental to assessing and improving process and equipment performance, much like cash flow is used to gauge a company’s financial health.

Table of contents

Definition of Cycle Time

Cycle time is the total time it takes to complete one cycle of a process from start to finish. This includes all the phases of the process such as setup, processing, and any delays or waiting periods.

It is a key performance metric in manufacturing, production, and service industries, used to measure the efficiency and speed of a process. Lowering it often leads to increased productivity and improved throughput.

Cycle Time as Process Cash Flow

Cycle time acts as a direct measure of process efficiency and equipment performance. By understanding and optimizing it, businesses can ensure that their processes are as lean and efficient as possible. This not only enhances productivity but also improves the overall financial performance of the company.

Key Components of Cycle Time

- Process Time: This is the actual time spent working on a task or producing a unit.

- Delay Time: This is the time when work is not being done on the task due to waiting for materials, approvals, or other dependencies.

Connecting Cycle Time to Lean Manufacturing

Lean manufacturing aims to maximize value by minimizing waste, and cycle time is a crucial metric in this approach. Improvements in cycle time often involve reducing idle time for machines and minimizing non-value-added work.

Management vs. Worker-Driven Improvements

In traditional mass production settings, management drives cycle time improvements with the goal of maximizing machine productivity. This approach focuses on making sure that machines are rarely idle and are used to their full potential.

In a Lean environment, workers who are intimately familiar with the tasks and processes often drive cycle time improvements. These workers identify inefficiencies and suggest improvements that can reduce cycle time and enhance overall productivity. This worker-driven approach ensures that improvements are practical and sustainable.

Cycle Time Reduction (CTR) Approach

CTR is different from traditional cost-cutting methods. It strengthens a company’s core capabilities and uses time as a strategic advantage. Here are some benefits and methods of CTR:

Benefits of CTR

- Decreased Investment in Inventory: Reducing cycle time decreases the investment in finished goods, work-in-progress (WIP) inventory, and the financing of receivables.

- New Market Opportunities: Faster order fulfilment and increased flexibility enable new market opportunities and strengthen pricing and customer loyalty.

- Higher Manufacturing Efficiency: Fewer changes to orders and production schedules lead to higher efficiency levels.

- Reduced Operating Costs: Decreased expediting, overtime, and costs associated with rush orders.

- Early Detection of Quality Problems: Increased inventory turns lead to earlier detection and resolution of quality issues.

Methodology of CTR

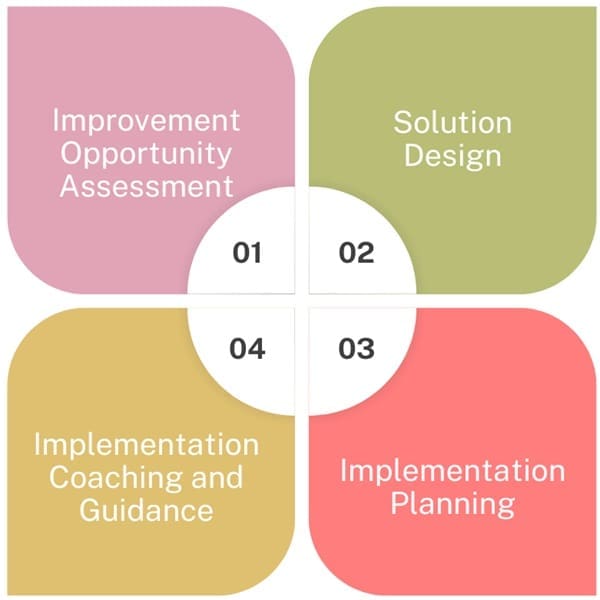

A four-step methodology for CTR can deliver rapid, dramatic, and sustained results:

- Improvement Opportunity Assessment: Conduct a detailed assessment to identify, quantify, and prioritize potential gains.

- Solution Design: Create and design solutions that address the identified opportunities from a high-level process perspective.

- Implementation Planning: Develop detailed implementation plans and a project performance measurement and tracking system.

- Implementation Coaching and Guidance: Provide coaching and guidance for the implementation of the designed solutions.

Cycle Time vs. Lead Time vs. Takt Time

Understanding the differences between cycle time, lead time, and takt time is essential for accurate performance measurement:

- Cycle Time: The time taken to complete a task or produce a unit.

- Lead Time: The total time from when an order is placed to when it is delivered.

- Takt Time: The rate at which products need to be produced to meet customer demand.

Difference Between Cycle Time, Lead Time and Takt Time

| Metric | Definition | Formula | Scope | Goal |

| Cycle Time | Time to produce a unit | Cycle time = Net production time / Units produced | Manufacturing process | Improve efficiency and productivity |

| Lead Time | Time from order placement to delivery | Lead time = Delivery date – Order date | Entire production process | Enhance customer satisfaction |

| Takt Time | Rate of production to meet demand | Takt time = Production hours / Customer demand | Production and manufacturing | Avoid over/underproduction, balance resources |

Calculating Cycle Time

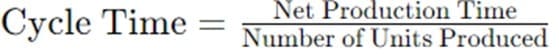

To calculate it, use the following formula:

Steps to Calculate Cycle Time

- Find Net Production Time: Subtract the time spent away from the project (e.g., breaks, meetings) from the total time allotted for active work.

- Calculate the Total Number of Goods Produced: Count the total number of units produced during the project.

- Perform Division: Divide the net production time by the total number of goods produced.

- Convert Value into Time: Multiply the decimal portion of the result by 60 to convert it into minutes.

- Interpret Results: Compare the results to your target cycle time to understand efficiency.

- Perform Routine Calculations: Regularly perform these calculations to maintain accuracy and refine processes.

Example

An online clothing company wants to measure the time to process a customer’s order. If their net production time is 7 hours per shift and they process 50 orders per shift:

Converting to minutes: 0.14×60=8.4 minutes per order

Benefits of Calculation

- Measures Efficiency: Indicates how efficiently a team completes a project.

- Identifies Areas for Improvement: Pinpoints slowdowns and opportunities for optimization.

- Shows Productivity: Highlights how well a company utilizes its production operations.

Cycle Time in Software Development

In the context of software development, it measures the speed at which a development team can deliver a feature to the customer. This metric measures the time from when work begins on a feature to when it is deployed and available to users.

Importance in Software Development

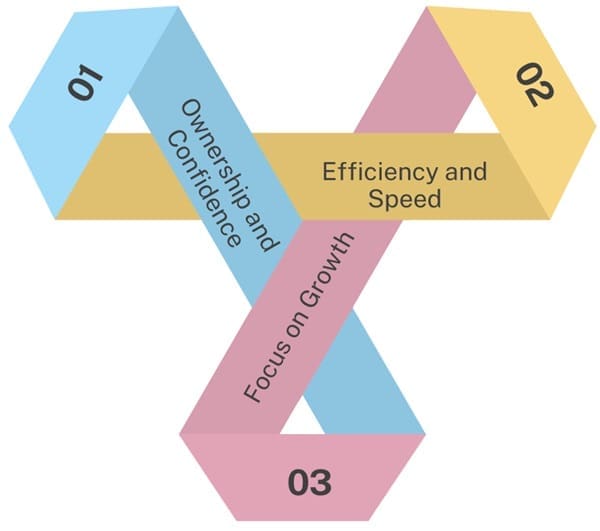

- Ownership and Confidence: Frequent shipping allows engineers to take ownership of their work and gives product teams confidence in their design and execution.

- Efficiency and Speed: Shorter cycle times lead to faster and more efficient development processes, reducing time to market, improving product quality, and increasing customer satisfaction.

- Focus on Growth: A streamlined development process allows the executive team to focus on growth and expansion, knowing that the development team is reliable and efficient.

Measuring Cycle Time in Software Development

Measure cycle time from the first commit to the deployment of the feature. This provides a clear indicator of the organization’s development velocity and helps identify bottlenecks and areas for improvement.

Frequently Asked Questions

How does it affect production?

Lower cycle times improve efficiency, reduce costs, and increase return on investment and profitability. They also correlate with higher customer satisfaction.

How do you reduce?

- Operate Parallel Tasks: Identify tasks that can run simultaneously.

- Eliminate Unnecessary Steps: Remove or combine non-essential steps.

- Reduce Delay Time: Streamline hand-offs and avoid bottlenecks by adding resources or automation.

Who calculates it?

Businesses across various industries, from manufacturing to software development, calculate it to improve efficiency and provide accurate estimates for stakeholders.

Final Words

Cycle time is a vital metric that reflects the efficiency of manufacturing and production processes. By understanding and optimizing it, businesses can enhance productivity, reduce costs, and improve customer satisfaction. Whether in traditional manufacturing settings or modern software development, focusing on cycle time can lead to significant improvements in performance and profitability.

By regularly calculating and analyzing it, companies can identify bottlenecks, streamline processes, and ensure continuous improvement in their operations.