Table of contents

- The Lean Six Sigma Yellow Belt Certification

- Who Can Take Up the Lean Six Sigma Yellow Belt?

- What are the Roles and Responsibilities of a Six Sigma Yellow Belt?

- Benefits of the Lean Six Sigma Yellow Belt Course

- How Do I Become a Certified Six Sigma Yellow Belt?

- Average Salary for a Six Sigma Yellow Belt Professional

- Related Articles

The Lean Six Sigma Yellow Belt Certification

Lean Six Sigma Yellow Belt Certification course is for those who are interested in a career in Quality Management and want to use 6S Methodologies to help make their projects successful and to have a higher salary range. The Yellow Belt-certified professionals will be involved in the project as Project team members and help Green and Black Belts ensure the project’s quality. They are responsible for driving basic improvement projects using Lean tools, and techniques.

Six Sigma Yellow Belt certification is the first step in the world of process improvements for professionals and people. The certification can be used to get a basic understanding and proficiency in Six Sigma and the phases of DMAIC (Define, Measure Analyze Measure, Measure, Control). Six Sigma is a step-by-step process of statistical tools, interventions, and analysis, which allows companies to interpret business processes, identify the root cause of problems, and maintain improvement gains.

Entry-level positions can be filled by Yellow Belt experts. They apply their Six Sigma knowledge to assist with Green Belt projects within organizations. They are responsible for small projects that follow the Plan, Do, Check, Act methodology, which makes it well worth the time investment.

Who Can Take Up the Lean Six Sigma Yellow Belt?

This course is ideal for those who want to start a career as a Quality manager. The training helps professionals to implement Six Sigma methodologies in their organizations for the success of their projects. The Yellow Belt would be a member of the Project team, supporting the Black Belts and Green Belts to maintain the project’s quality. A Yellow Belt professional would need to be proficient in Lean tools and techniques in order to drive basic improvement projects.

What are the Roles and Responsibilities of a Six Sigma Yellow Belt?

Lean Six Sigma Yellow Belt certification course provides an overview of LSS and basic methods for improvement. Lean Six Sigma Yellow Belt-certified individuals will be able to use Lean Six Sigma methods for improving production and transactional systems to meet customer needs and reach organizational goals.

- They often manage small-scale process improvements using the PDCA process. These small-scale PDCA projects may be taken up to Black Belt or Green Belt level if necessary. In this case, the DMAIC methodology is used to maximize cost savings with more advanced statistical tools.

- Yellow Belt professionals are expected to be able to use the methodologies to improve production and transactional systems to meet customer expectations and achieve organizational objectives.

- They are often responsible for small process improvement projects using PDCA. A Yellow Belt can use PDCA to identify a process where improvement could be made. These small projects can be escalated to Black Belt or Green Belt levels, where DMAIC methodology is used for maximum cost savings using Statistical Process Control.

- They can understand the process and align themselves with the company’s goals. They can help Black Belts and Green Belts with their projects.

Benefits of the Lean Six Sigma Yellow Belt Course

Many people want to be certified to the highest level. This is why many people skip to the Black Belt. Although this is not necessarily a bad approach, earning a Yellow Belt can have many benefits:

A Better Understanding of the Roles

It is essential to be familiar with the roles of the Green belt, Yellow belt, and Black belt to obtain a Black Belt. This exam is geared towards the Yellow Belt level. This exam will give you an overview of specific tasks Yellow Belts perform for a given project. Because they do not possess the statistical skills of a Green Belt it is not possible for them to perform such tasks. Yellow belts can understand basic Six Sigma principles like y=f (x), Process Variances and DMADV variation, ISO, and Needs Analysis.

Great for your Resume

Employers will be impressed by an SSYB on their resumes. This shows that you are committed to the DMAIC process and that you have passed the exam to ensure quality. Employers are always on the lookout for people who can reduce waste and save money. LinkedIn can help you get more exposure by allowing employers to search for the skills they are looking for.

Possibility of High Salaries

While the certification does not guarantee a higher salary but will make you more valuable to your employer, Employers are always looking for people with different skill sets in this high-skilled market.

How Do I Become a Certified Six Sigma Yellow Belt?

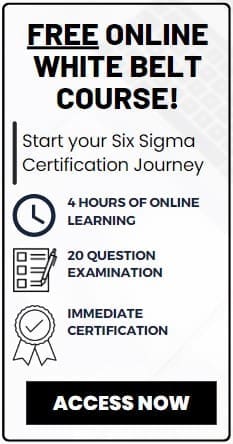

At Six Sigma Development Solutions, Inc. (SSDSI), we can guide you through the process of getting SSYB through IASSC, CSSC, American Quality for Quality (AQS), or our firm respectively.

To become a Certified Six Sigma Yellow Belt there are no pre-requisites. Here’s a list of best practices and steps to follow:

- Research and Understand Six Sigma: Get acquainted with the principles, methodologies, and concepts behind Six Sigma to better comprehend its purpose, benefits, and implementation across industries.

- Search Training Providers: Locate reliable training providers offering Six Sigma Yellow Belt certification courses.

- Attend and Actively Engage in Yellow Belt Training: Attend and actively engage in the Yellow Belt training course to learn fundamentals of Six Sigma such as basic statistical tools, DMAIC methodology (Define, Measure, Analyze, Improve, and Control), process mapping, and other essential concepts.

- Complete a Lean Six Sigma Yellow Belt project

- (Optional) Study and Prepare: Once the training course has been concluded, review its materials, and examine any topics covered to prepare yourself for any certification exams that might follow.

- (Optional) Take the Certification Exam: For Yellow Belt certification exams, contact your training provider or certification body in advance to arrange them online or in person, depending on how the organization chooses to administer them. Typical questions from this type of exam focus on course content with multiple-choice options that must be answered correctly to pass.

- (Optional) Pass the Exam: Prepare thoroughly and attempt the certification exam; passing scores may differ depending on your organization, so make sure you fully understand its criteria prior to sitting for it. If successful, your Six Sigma Yellow Belt certification will be awarded!

- Continued Education: Consider expanding your knowledge and abilities by attaining higher-level Six Sigma certifications such as Green Belt or Black Belt to further your Six Sigma expertise.

Does Six Sigma DSI offer Lean Six Sigma Yellow Belt Training?

Yes, we offer Lean Six Sigma Yellow Belt training.

- The course is full of games, videos, and simulations.

- We use interactive tools to learn how to reduce waste (complexity) in a process and increase the capacity to do work without adding more employees.

- We play with dice, Legos, and airplanes to bring the LEAN Six Sigma Methodology to life.

What is included in our Lean Six Sigma Yellow Belt course?

- LEAN and Six Sigma Concepts Overview

- Using the Pareto Chart to Focus the Project

- Developing the Project Charter

- Showing Baseline Statistical Control and Capability

- Completing the SIPOC to Ensure the Correct Focus

- Value Stream Mapping (VSM) to Identify Waste

- Using the “Quick Change Process Mapping Technique” for Process Discovery

- Root Cause Analysis using the Fishbone

- How to Select, Manage, and Control the Right Solutions

- Showing Improved Statistical Control and Capability

Average Salary for a Six Sigma Yellow Belt Professional

Yellow Belts are qualified for positions such as:

- Operation Manager

- Quality Engineer

- Process Engineer

- Manager Supply Chain

- Analyst in Business Process.

Lean Six Sigma Yellow Belt salary professionals earn an average salary of $70,000 to $100,000 annually. Your experience also plays a role in the salary of a Lean Six Sigma yellow belt. For Lean Six Sigma yellow belts with less than 1-4 years of experience, the average salary is $99,761 per year according to indeed.com.

Vital Facts That All Yellow Belts Should Know

- Yellow Belts are familiar with the basics of Six Sigma.

- You will spend both money and time on a certification program like a Yellow Belt. The yellow belt course will explain the basics of the methodology, and when to use them.

- Yellow Belts also need to be disciplined enough to stick with one task at a time and obey the project manager’s orders. These tasks may include data mining or organization tasks.

- As a Yellow Belt, you will also be expected to teach other employees the Six Sigma method.

- Six Sigma Yellow Belts must also be able to accept and recognize constructive criticism from their managers.

- PDCA is a key element of the Six Sigma Yellow Belt Curriculum.

- Data collection is another area where Yellow Belts should have no problem. The Yellow Belt’s role is to gather data from various sources, organize it, and deliver it to management or other roles.

- Each Yellow Belt should also know how to monitor the different processes.

- A Yellow Belt must also be able to create simple graphs using data. These graphs can include histograms and linear regressions. They also include heat maps.

- As a Yellow Belt, you will need to be driven by the desire to improve your business processes. Every process, whether it’s in manufacturing, production, or planning, can be improved.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.

i want start the yellow belt