Table of contents

What is Lean Management?

Lean Management systems optimize processes by reducing the time spent on tasks that are not value-added (such as unnecessary operations, transport, waiting, and overproduction). Lean Management aims to reduce the time spent on non-value-added tasks (unnecessary operations or transport, waiting, overproduction, etc.). It also focuses on reducing the causes of poor quality. This method is supported by an important management dimension that ensures employees are working in the best conditions. There are two main goals: complete customer satisfaction and success for each employee.

Lean Management, a key phrase in English that was formalized by American researchers from the Massachusetts Institute of Technology, is an expression developed by American researchers. In essence, “Lean” means “no frills”. This is a reflection of the principle of cutting down to the essentials, removing all the extraneous.

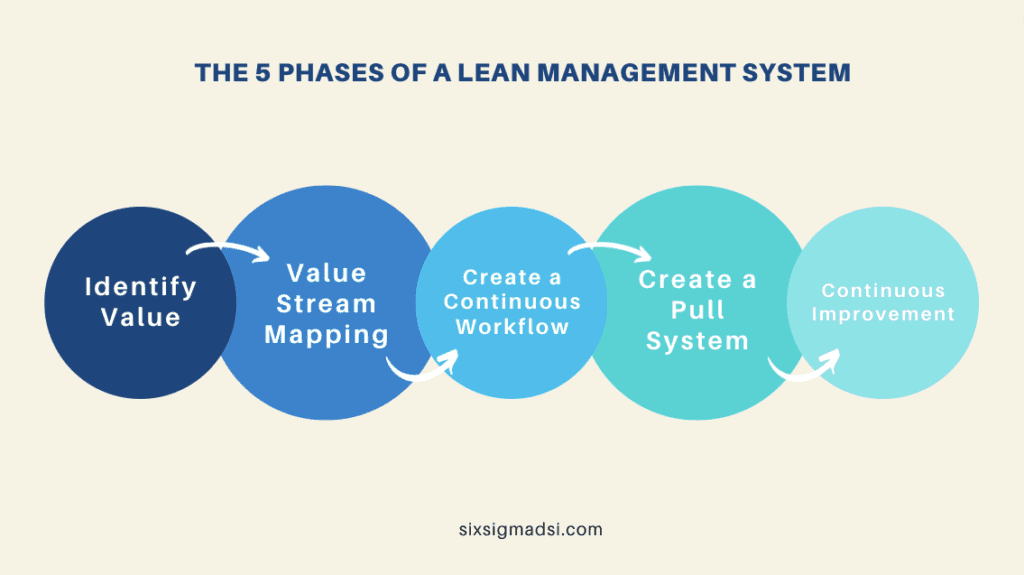

What are the five phases of a Lean management system?

1. Identify Value

What is the goal of every business? Offer a product or a service that the customer is willing to pay for. In order to do this, a business must add value based on the needs of its customers.

You can find value in solving a customer’s problem. The value is in the part of your solution that you are willing to charge for. Waste is any activity or process which does not add value to your product.

In lean, the value must be identified first. Decide what you are trying to achieve, and then proceed to the next steps.

2. Value Stream Mapping

You need to literally map out the workflow in your company. This should include all the actions and people who are involved in getting the product to your customer. You will then be able to identify which parts of the process are not valuable.

The value-stream mapping principle will help you identify where and how much value is generated in the process.

You will find it much easier to identify which teams are responsible for what processes and who is in charge of measuring, evaluating, and improving them when you map your value stream. This will help you identify the steps that are not adding value, and eliminate them.

3. Create a Continuous Workflow

You need to ensure that the workflow of each team remains fluid after you have mastered your value stream. Remember that it could take some time.

Cross-functional teams are often involved in the development of a new product or service. At any moment, bottlenecks or interruptions can occur. By visualizing your workflow and breaking work down into smaller batches, you can detect and remove roadblocks.

4. Create a Pull System

A stable workflow will allow your team to complete tasks faster and with less effort. To ensure a stable workflow when using the Lean method, you should create a Pull System.

This system only pulls work if it is needed. It allows you to optimize the capacity of your resources and only deliver products or services if they are actually needed.

Take a restaurant as an example. You order pizza at the restaurant. The baker takes your order and begins making your pizza. The baker doesn’t make a lot of dishes because the demand isn’t there. This can lead to wasting resources.

5. Continuous Improvement

You have now built your Lean Management System after completing all the steps. Don’t overlook this final step. It is probably the most crucial.

Remember that your system is not static and isolated. Any of the steps could cause problems. It is important that all employees are actively involved in the improvement of the process.

Different techniques can be used to encourage continual improvement. Every team could have a stand-up meeting every day to discuss what’s been done, what still needs to be done, and any obstacles. This is a simple way to make improvements each day.

What is the core principle of Lean Management?

To implement Lean Management successfully within your company, you must follow the five core principles of the method.

1. Value identification

What is the goal of every business? Offer a service or product that the customer will pay for. In order to do this, the company must add value as defined by their customers’ needs.

Your company’s value lies therefore in its ability to solve a customer’s problem, and more specifically in the part of that solution for which the customer is willing to pay. Waste is any activity or process which does not add to the value of the final product.

You should then clearly define the value that you will bring to your offer. You can move more quickly to the next step if you complete this first one.

2. Value chain mapping

Here you need to literally map out the workflow in your business. It should include the actions and the people who are involved in the delivery of the final product to the client. You will then be able to identify those steps that don’t add value.

This principle can be used to determine where and how much value is added by each step of the process.

You will find it much easier to identify which processes are the responsibility of which teams, and who is responsible to monitor, evaluate and improve each process, once you have created your value chain. This overview allows you to eliminate steps that don’t add value.

3. Create a continuous workflow

After you’ve mastered your value chain you’ll need to make sure that the workflow of each team is smooth. It may take some effort.

Interdepartmental collaboration is often required when developing a new product or service. Any bottlenecks or interruptions may occur. By visualizing your workflow and breaking tasks down into smaller pieces, you can detect and remove any obstacles.

4. Create a traction device

Your teams can complete their tasks faster and more efficiently with a stable workflow. To ensure stability, it is important to implement a traction-based system in the Lean framework.

In a similar system, only work is produced when it is needed. So, the capacity is maximized. Resources are only mobilized if there is a concrete and real need.

Imagine a restaurant. You enter the restaurant and place your order. The restaurant takes your order and begins preparing your meal. He doesn’t cook large quantities of dishes in advance because there isn’t a real demand for them and they could end up being wasted.

5. Continuous improvement

You have now built your Lean Management System. Pay attention to the last step, which is arguably the most important.

Keep in mind that your system does not exist in isolation. Any of the steps can cause problems. You will want to involve employees of all levels in the process improvement.

There are many ways to encourage continuous improvement. Each team could hold a meeting every day to discuss the progress made, the obstacles, and what needs to be done. This is a simple way to improve your process each day.

Lean principles are gaining in popularity because they improve all aspects of the work process, and involve all levels within a company.

Lean Management: Different tools

Lean management systems have tools that can be described as solutions for learning and experimenting. The staff adopts them and works together in a continuous improvement process.

Here are some examples of the many tools that are available:

- Use the 5S method to optimize your working environment and reduce waste time.

- Six Sigma is a method for improving the quality and efficiency of processes.

- Visual management for sharing information and solving problems

- Kaizen is a method of continuous improvement that uses the Kaizen principle.

- The SMED method reduces the time required for series changes;

- Kanban is a method of inventory management that optimizes the use of stock.

- Value Stream Mapping is a method that helps to identify and analyze process obstacles.

Lean Management, which originated in the automobile industry, is now widely used, irrespective of company size or sector. The concept was also adapted as in Lean Purchasing which emphasizes operational excellence within procurement departments.

Do you have experience creating Lean Management Systems?

Tell us about it in the comments below!