Table of contents

- What is Kanban Inventory Management?

- Kanban Core Practices

- Common Problems in Supply Management and Inventory Management

- Kanban Inventory Guidelines

- Why use a Kanban Inventory Management application?

- You can make specific Kanban projects based on your inventory type

- Kanban Cards to Identify Inventory Items

- Related articles

What is Kanban Inventory Management?

Kanban system of inventory management application basically means that you have to keep only as much stock as is needed at any given time. This prevents you from purchasing more stock than you actually need and allows you to store the extra inventory in a smaller space. Kanban can be used to prevent bottlenecks in your workflow.

Kanban is an ideal visual tool for managing inventory flow. It was created by Taiichi Ohno (an industrial engineer at Toyota) around three-quarters of a century back. Kanban boards allowed Toyota to stock its inventory only when it was necessary. This revolutionary approach helped Toyota grow quickly.

Customers are expecting faster fulfillment, especially with mobile access. However, supply chains are becoming more complex and distributed across multiple facilities. A Kanban inventory system is an effective inventory management system that can reduce costs and give you a competitive edge.

What is Kanban?

Kanban is a system of inventory control used in Just-in-Time (JIT). The system was created by Taiichi Ahno, a Toyota industrial engineer, and is named after the colored cards used to track production and order new materials or parts as needed. Kanban, a Japanese term that means “visual card”, is the basis of the kanban process.

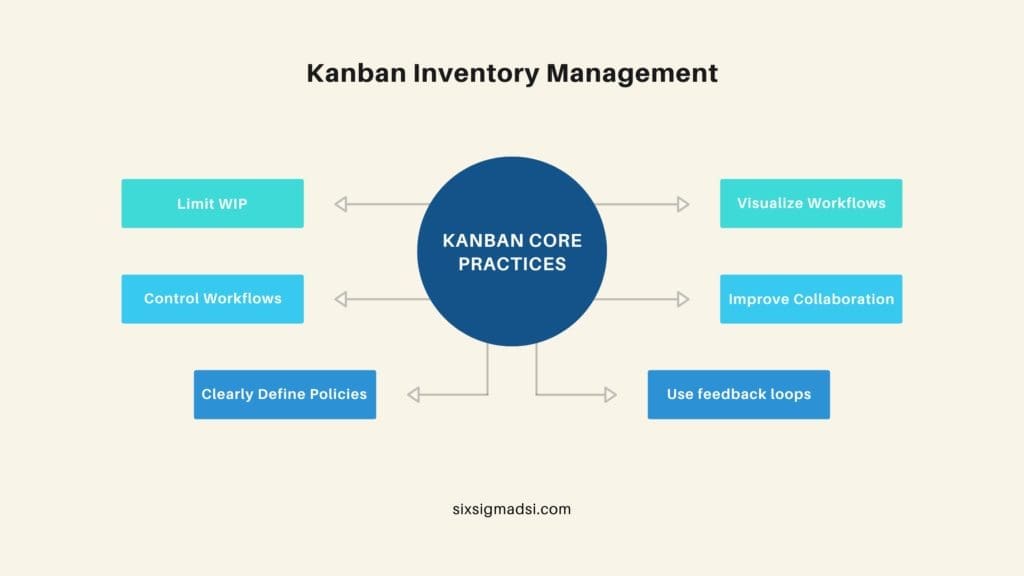

Core Practices in The Kanban System

Kanban has many core principles that guide how processes are done and how team members can be involved.

Visualize Workflows

The process must be clearly illustrated to make kanban work. The process must be clearly illustrated using visual cues. It is important to clearly explain each step, what is expected, and who will do what tasks.

An old-fashioned method that is still in use today is to draw kanban tasks on sticky notes. To signify different work items, each sticky note could be colored in a different way. To make it easier to organize the tasks, they would be divided into swim lanes. Today, Kanban is driven by inventory software.

Limit WIP

Kanban is founded on efficiency and aims to reduce work in progress. Prior tasks are completed by teams before they move on to the next one. This allows future dependencies to be established earlier, and staff can start their tasks sooner than they need.

As it goes through the kanban process, a company must determine the amount of work in progress that it should be carrying. This can be tied to how many people are involved in the project. As the number decreases, the permitted number of items is also reduced. This restriction also informs other departments and teams that they need to be mindful of the requests of other teams, as each group may be subject to a working limit.

Control Workflows

A company can identify its strengths and weaknesses as it goes through the process. Sometimes limitations or goals are not met. In these cases, the company must manage the workflow to overcome shortcomings.

The Kanban application’s most important part is to identify and remove bottlenecks before they occur. Forecasting production and resource usage are two examples. A company will be able to make more predictable commitments to customers and make its processes more efficient by scaling back unused resources.

Clearly Define Policies

Processes are often clearly described as part of visualizing workflows. The expectations of departments can be easily understood by their teams. Kanban cards that are assigned to individuals clearly indicate the responsibilities for each task. Each worker will be able to understand the expectations and checklist criteria that must be met before they can complete a task. They also know what happens during transitions between steps.

Use feedback loops

Companies often use the kanban technique to gather information, analyze the flow of the process, and then make changes to improve it. Employees can continuously improve their work and implement small, incremental improvements that are more easily adapted. Feedback can be positive or negative. Kanban is a method to quickly identify and fix problems early on in the process. This allows companies to adjust to the correct path before they become more serious.

Improve Collaboration

Individuals must often rely on each other because tasks are broken down into small kanban cards. Individuals must work together and plan for transitions between the swim lanes. Other individuals need to collaborate with each other and find solutions quickly. Kanban requires that all changes to the process be communicated broadly as any adjustments made in one area could have an even greater impact on another.

Common Problems in Supply Management and Inventory Management

A supply chain can slow down due to many factors. If you are being supplied by multiple warehouses, or worse, multiple countries, this can cause a supply chain to slow down. However, Kanban Cards can be used to represent all of the links in your supply chain. They make it easier for you to coordinate deliveries and help you know where everything is.

Incorrectly identifying and evaluating business needs can lead to inventory management problems. Knowing where there are gaps in your system is crucial so that you can prioritize filling them. Kanban inventory systems application provides a visual map that shows you what you need when it is needed and where. To make sure that both sides are realistic, you can align the Kanban inventory system with your business plans.

However, if your inventory system doesn’t work well, you won’t be able to forecast future inventory requirements. A kanban board’s cards are used to capture inventory and identify where it is in the pipeline. This allows you to spot opportunities and take action to improve the supply chain.

Kanban Inventory Guidelines

Six rules guide a Kanban system, according to the Toyota factory.

- Do not pass defective products. Upstream processes should meet the quality standards and requirements. All defective products must be removed. They are handled outside of the production line.

- Only take what you need: The downstream processes only take what you need to avoid overproduction. This reduces costs and allows operations to reflect market needs.

- Make exact quantities: Avoid excess production, which can lead to more inventory and higher costs.

- Maintain a level of production. Maintain a steady flow of work.

- Optimize and fine-tune the process: Continue to look for ways to increase efficiency after implementing kanban.

- Stabilize the process Maintain high quality, optimize production, and standardize processes.

Why use a Kanban Inventory Management application?

A successful business venture requires you to monitor and optimize your inventory levels while also meeting customer requirements. This will reduce the cost and level of your inventory. Avoid unnecessary storage costs by only storing what you need, when you need it, and replenishing the stock promptly.

It’s akin to the old cartoon about a steam engine moving through pristine terrain, with a worker tearing up the track behind the train and placing it before it as it goes. Although it’s absurd, it makes sense. Use what you need when you need it. You don’t need to be miles ahead of the curve. What if you had to pay for storage?

Customer Needs

Kanban is more than just a way to maintain minimum inventory levels. It also responds quickly to customer needs. You can identify which products are most popular and restock only what you need. Inventory is driven by the customer, which is correct as the customer will purchase the inventory.

Get quick status reports

Managers also have the benefit of easy access to progress reports. Managers can view what has been done, where it is in production, and when it’s finished. The Kanban board displays all this information in a visual and simple way. This creates simple-to-read charts and graphs for various project metrics.

Cleaner Warehouse

A Kanban application helps keep the production area clear of any unnecessary storage. Kanban ensures that you only deliver the parts to the production line as necessary. This allows production space to be focused on production and not storage. All these ties in nicely with Lean Manufacturing, which promotes continuous product flow through the manufacturing process.

You can make specific Kanban projects based on your inventory type

Our project management software allows you to create projects for each type of Kanban inventory. This will allow you to quickly check how much inventory you have inbound and outbound for a particular product type. Let’s suppose you are stocking shoes for the company. Create a new project in the software and then create your Kanban board to track your shoe inventory.

Traditional kanban boards are divided into three columns. However, you can change their names to fit your business needs. The “To-Do” column is where tasks are identified. For tasks currently being completed, there is a “Doing” column. Finally, you can place tasks that have been completed successfully in the “Done” column. This allows you to easily track your work by moving the tasks across the columns boards.

Kanban Cards to Identify Inventory Items

The kanban inventory management system application breaks down the production into tasks so that a manager can monitor and track each step of the production cycle. Every inventory item, shipment, or other tracking metric is placed on a card. As they are being worked on, these items are moved from one column to the next.

Each card contains the information required to complete the task at each stage of production. This includes supplies and materials that may be needed further down the line.

Have you used a Kanban Inventory Management application?

Which one do you recommend? Leave a comment down below.