The 8D (Eight Disciplines) problem-solving methodology is a systematic, team-based approach used to address and resolve complex problems in various industries.

The U.S. military originally developed 8D during World War II. Later, in the 1980s, Ford Motor Company popularized it, and it is now widely recognized in the automotive, manufacturing, and engineering sectors.

The approach focuses on identifying, analyzing, and correcting root causes of problems to prevent their recurrence. Its structured process emphasizes teamwork, data-driven decisions, and fact-based analysis, making it highly effective in ensuring product and process improvements.

Table of contents

What Is a Problem?

In the context of 8D, we define a problem as a deviation from a set target or goal. Specifically, this target could be pre-determined by customers, stakeholders, or agreed upon within the organization.

Problems may not always be evident at the start of a project; they can emerge at any point in the product development lifecycle. There are generally three types of deviations:

- Instantaneous Deviation: The problem appears suddenly without warning.

- Gradual Deviation: The issue emerges over time, often as performance slowly worsens.

- From the Beginning: The problem has been present since the start of a process or product lifecycle but may not have been immediately identified.

Typically, a problem arises when:

- The causes are unknown.

- There is a risk of negative consequences.

- The complexity of the issue requires the involvement of a team to resolve.

When to Use 8D Problem Solving?

The 8D methodology is particularly beneficial when:

- The root cause of the issue is unclear.

- The problem has significant risks or consequences, such as safety concerns or product failure.

- A problem requires team collaboration to solve due to its complexity.

The primary strengths of 8D include:

- Its simplicity and effectiveness in eliminating root causes.

- Its ability to prevent the recurrence of problems.

- Its potential to optimize time by providing quick and efficient solutions for similar cases in the future.

What is 8D?

The 8D (Eight Disciplines) methodology is a problem-solving process designed to identify, correct, and eliminate recurring problems. It is a highly effective technique that focuses on uncovering the root cause of a problem and implementing permanent corrective actions.

The approach was first developed by the Ford Motor Company in the 1980s and is still widely used in various industries today. The “eight disciplines” refer to the eight key steps that guide teams through the process of solving complex problems in a structured way.

Why the 8D Methodology?

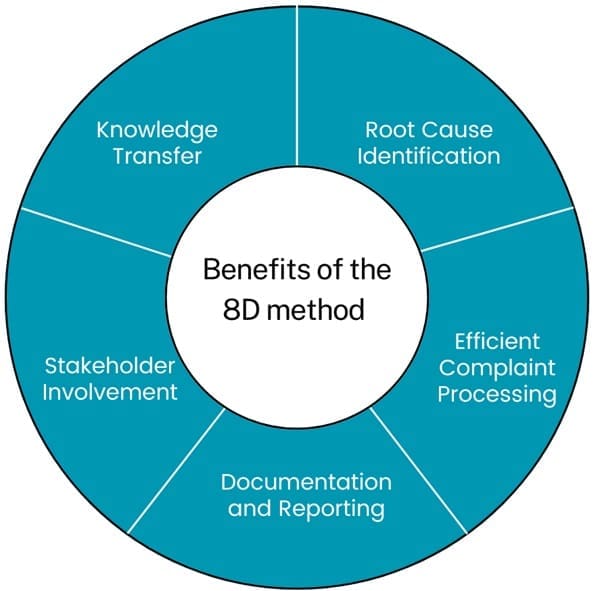

The primary goal of the 8D methodology is to eliminate problems in products or processes and to prevent their recurrence. Its systematic approach makes it a highly effective tool for enhancing efficiency in problem-solving. Key benefits of the 8D method include:

- Root Cause Identification: The methodology enables teams to accurately identify the underlying cause of a problem.

- Efficient Complaint Processing: Both internal and external complaints can be addressed in a timely and structured manner.

- Documentation and Reporting: The 8D process ensures that problem-solving steps are documented continuously and systematically.

- Stakeholder Involvement: The approach encourages involving relevant stakeholders, especially in cross-functional teams, to ensure comprehensive problem resolution.

- Knowledge Transfer: Lessons learned from the 8D process can be applied to future projects, helping prevent similar problems from arising again.

Comparison of 8D with Other Problem-Solving Methods

In addition to 8D, two other widely used problem-solving methodologies are PDCA and Six Sigma:

- PDCA (Plan-Do-Check-Act): This approach involves continuous improvement cycles through planning, execution, verification, and corrective actions. PDCA is ideal for problems of low complexity and where multiple employees are involved in the problem-solving process.

- Six Sigma (DMAIC): This data-driven method focuses on improving existing processes by defining, measuring, analyzing, improving, and controlling (DMAIC) process variables. It is a more rigorous and statistical approach than 8D and is commonly used for complex problems that require specialized knowledge and statistical tools.

- 8D: Unlike PDCA and Six Sigma, the 8D methodology is more focused on customer complaints or quality issues. It follows a structured, step-by-step approach to solve problems, with a specific emphasis on immediate containment actions to minimize customer impact and prevent further issues.

All three methods rely on problem-solving tools like 5 Whys, Fishbone Diagrams (Ishikawa), and brainstorming sessions. However, Six Sigma includes more advanced statistical tools like hypothesis testing, Design of Experiments (DOE), and Analysis of Variance (ANOVA), often requiring specialized software like Minitab.

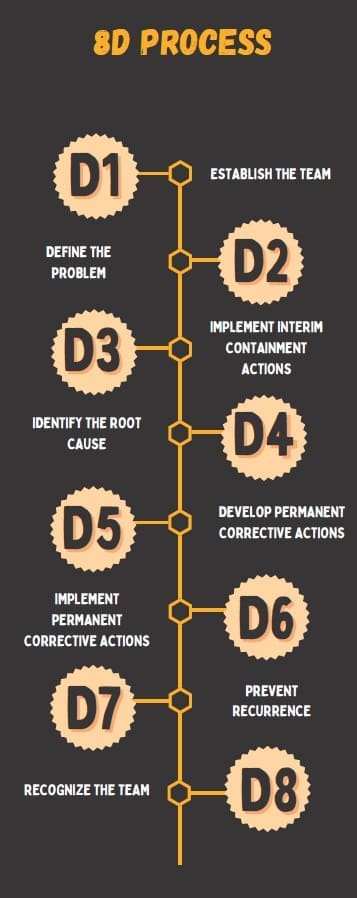

8D Process

The 8D methodology consists of eight steps, each representing a “discipline” that addresses specific aspects of the problem-solving process. These steps ensure that the problem is well understood, the root cause is identified, and corrective actions are implemented to prevent the issue from recurring.

D1: Establish the Team

The first discipline involves forming a cross-functional team with the right skills, knowledge, and authority to solve the problem.

A team leader is usually appointed to oversee the entire process. This team typically includes members from various departments such as quality control, engineering, production, and customer service. The key is to have a diverse group with the expertise necessary to analyze the problem from multiple angles.

D2: Define the Problem

This step requires the team to clearly describe the problem in detail, focusing on answering questions like “What is happening?” and “Where is it happening?”. A good problem statement is specific and quantifiable, outlining the issue in terms of who is affected, what is affected, when the issue occurs, and how often it happens.

D3: Implement Interim Containment Actions

At this stage, the team implements temporary measures to contain the problem and prevent it from causing further issues. Containment actions must be quick and effective to prevent the problem from spreading.

As a result, these actions ensure that the customer or downstream processes do not experience further impact. However, the team does not design these actions to provide a permanent solution to the problem.

D4: Identify the Root Cause

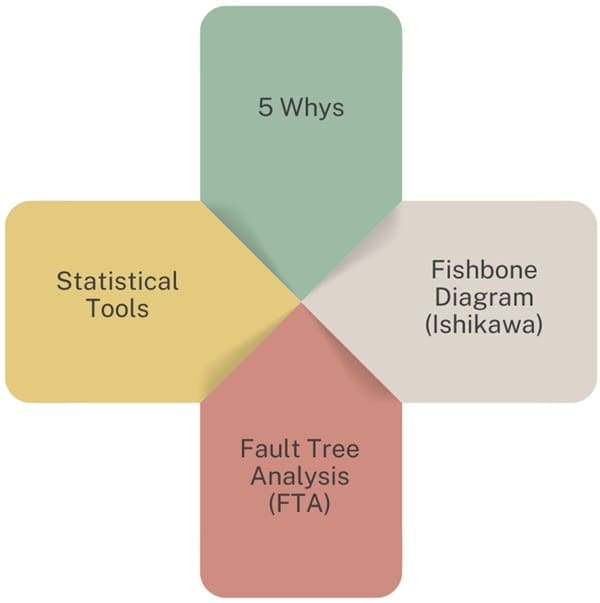

In this step, the team must investigate and pinpoint the root cause of the problem. There are various tools that can help with root cause analysis, depending on the nature and complexity of the issue:

- 5 Whys: This is a simple but powerful technique where the team asks “Why?” five times (or more) to drill down into the root cause of a problem.

- Fishbone Diagram (Ishikawa): This tool helps organize potential causes into categories like “People,” “Methods,” “Machines,” “Materials,” “Measurement,” and “Environment,” visually displaying how various factors contribute to the problem.

- Fault Tree Analysis (FTA): This method involves breaking down the problem into multiple layers. Furthermore, it requires analyzing potential causes and working through each layer until the true root cause is identified.

D5: Develop Permanent Corrective Actions

Once the team identifies the root cause, they develop long-term corrective actions that permanently eliminate the problem. Additionally, they must test these actions to ensure they effectively address the root cause. Finally, the team verifies the results to confirm the effectiveness of the implemented solutions.

At this stage, it’s important to consider the most efficient and cost-effective solution that will prevent the problem from recurring.

D6: Implement Permanent Corrective Actions

After the team develops and verifies the corrective actions, they must implement them. Furthermore, the team should monitor the implementation to ensure that they carry out the actions correctly. Finally, this monitoring will confirm whether the actions effectively resolve the problem.

This step may involve process changes, retraining employees, or updating documentation to reflect the new practices.

D7: Prevent Recurrence

In addition to solving the immediate problem, the team must take steps to ensure that similar issues do not occur in the future. This often involves revising company policies, updating procedures, or introducing new quality controls. The team should also document the lessons learned from the process, so that future teams can avoid making the same mistakes.

D8: Recognize the Team

The final step is to celebrate the success of the team and recognize their efforts in solving the problem. This can be done through formal recognition programs, awards, or simply acknowledging their hard work in team meetings. Recognizing the team’s contribution boosts morale and encourages a proactive problem-solving culture within the organization.

Timeline of the 8D Process

The team designs the 8D process to be both thorough and timely. Typically, the process follows a structured timeline:

- Within 2 days, the team should complete D1 and D2 (team formation and problem definition), along with initial containment actions (D3).

- Within 7 days, the team should finish the root cause analysis (D4) and update the 8D report with findings.

- Within 14 days, the team should define corrective actions (D5) and outline implementation steps (D6).

- Within 60 days, the team should finalize the entire 8D report, including verification of corrective actions and preventive measures.

Root Cause Analysis Tools in 8D

Root cause analysis serves as the heart of the 8D process, and teams can use various tools depending on the complexity and nature of the problem:

- 5 Whys: This tool proves most effective for simple, well-defined problems. By repeatedly asking “Why?” the team traces the problem back to its root cause.

- Fishbone Diagram (Ishikawa): Teams use this tool for more complex problems with multiple potential causes. It organizes these causes into categories, allowing the team to systematically investigate each one.

- Fault Tree Analysis (FTA): Teams employ FTA as a more advanced tool for multi-parameter problems with many potential causes. It breaks the problem down into layers, enabling the team to eliminate possible causes one by one.

- Statistical Tools: For highly complex problems, teams may require statistical methods like Design of Experiments (DOE) and hypothesis testing to identify the root cause. These tools typically support Six Sigma projects but can also integrate into the 8D process when needed.

8D vs. Six Sigma

While both 8D and Six Sigma aim to solve problems and improve processes, they differ in their focus and approach.

- 8D is primarily used for reactive problem-solving, especially when dealing with customer complaints or quality issues. It focuses on resolving specific incidents and ensuring that they do not recur.

- Six Sigma, on the other hand, is a proactive, data-driven methodology aimed at reducing process variation and improving overall quality. Six Sigma projects are more complex and typically involve statistical analysis to improve processes over the long term.

The 8D process also includes the unique step of interim containment actions, which is not part of Six Sigma or PDCA. This step ensures that the problem does not worsen while the team works on identifying and resolving the root cause.

Benefits of the 8D Methodology

The 8D methodology offers several key benefits to organizations:

- Structured Approach: The 8D process provides a clear, step-by-step method for solving problems, making it easy to follow and implement.

- Team-Based Problem Solving: The cross-functional nature of the 8D process ensures that teams consider different perspectives, leading to more comprehensive solutions.

- Focus on Root Cause: This methodology emphasizes identifying and addressing the root cause instead of simply treating symptoms.

- Prevention of Recurrence: By implementing corrective actions and improving processes, the 8D approach prevents problems from recurring.

- Immediate Containment: The interim containment actions minimize the impact of the problem while the team develops a permanent solution.

Final Words

The 8D methodology is a powerful problem-solving tool that helps organizations address issues quickly and effectively. By focusing on the root cause and implementing long-term corrective actions, 8D ensures that problems are resolved and do not recur.

When used alongside other problem-solving methodologies like PDCA and Six Sigma, 8D provides a comprehensive approach to improving quality, reducing costs, and maintaining customer satisfaction.

With its structured process, team-based approach, and emphasis on long-term solutions, the 8D methodology is a valuable asset for any organization looking to improve its problem-solving capabilities.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.