Fault Tree Analysis (FTA) is a systematic, top-down method for analyzing the potential causes of system failures or accidents. It starts with a single undesirable event, known as the “top event,” and works downwards to identify all possible causes. This method is widely used in risk and reliability studies, particularly in engineering and safety-critical industries.

Table of contents

Definition of Fault Tree Analysis

Fault Tree Analysis (FTA) is a systematic, deductive methodology used to determine the root causes of an undesired event (called the top event) in a system.

It uses a graphical model resembling a tree, with the top event at the root and various contributing factors branching downward through logical gates (AND, OR). Each branch represents a failure pathway, helping identify potential points of failure.

FTA is widely applied in safety engineering, risk assessment, and reliability engineering to enhance understanding of complex systems, prioritize safety measures, and prevent failures by addressing their root causes.

History and Development of FTA

FTA was first developed in 1962 by Bell Telephone Laboratories for the U.S. Air Force’s Minuteman missile launch control system. The technique was later refined by Boeing and has since become a standard tool in various industries. One notable application was in the Reactor Safety Study (WASH-1400), which extensively utilized and extended the method.

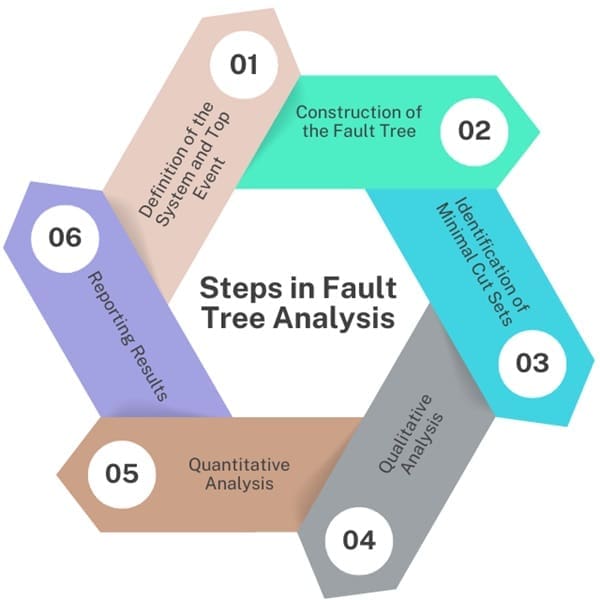

Steps in Fault Tree Analysis

- Definition of the System and Top Event: Clearly define the system under analysis, the top event (the potential accident or failure), and the boundary conditions. Boundary conditions include the physical boundaries of the system, initial operational states, external stresses (like war or natural disasters), and the level of detail required for the analysis.

- Construction of the Fault Tree: Begin with the top event and identify all immediate, necessary, and sufficient conditions causing it. These conditions are connected using logic gates (AND and OR gates). The analysis proceeds downwards until reaching basic events, which are independent and for which failure data is available.

- Identification of Minimal Cut Sets: Determine the minimal combinations of basic events that can lead to the top event. These are known as minimal cut sets.

- Qualitative Analysis: Analyze the fault tree to understand the various paths that can lead to the top event. This involves identifying the minimal cut sets and understanding the logical relationships between different events.

- Quantitative Analysis: If data is available, perform quantitative analysis to determine the probability of the top event occurring. This includes calculating system unavailability, unreliability, and failure rates.

- Reporting Results: Document the findings of both the qualitative and quantitative analyses. This report should include a clear explanation of the fault tree, the identified minimal cut sets, and the calculated probabilities of failure.

Preparation for FTA

Before conducting an FTA, it is essential to have a thorough understanding of the system. This often involves conducting a Failure Modes, Effects, and Criticality Analysis (FMECA) and creating a system block diagram. These tools help identify the potential failure modes and their effects on the system, providing a solid foundation for building the fault tree.

Construction of Fault Tree

- Define the Top Event: The top event should be clearly defined, answering questions like “What?”, “Where?”, and “When?”. For example, “Fire in the process oxidation reactor during normal operation”.

- Identify Causes: Determine the immediate causes of the top event and connect them using AND or OR gates. AND gates indicate that all input events must occur simultaneously for the output event to happen, while OR gates indicate that the output event occurs if any of the input events occur.

- Proceed to Basic Events: Continue this process until reaching basic events, which are independent events with available failure data.

Symbols used in Fault Tree

- OR Gate: The output event occurs if any of the input events occur.

- AND Gate: The output event occurs only if all the input events occur simultaneously.

- Basic Event: Represents a fundamental failure that requires no further breakdown.

- Undeveloped Event: An event that is not analyzed further, either due to lack of information or its insignificant consequences.

- Transfer Symbols: Indicate that the fault tree continues in another part of the diagram.

Fault Tree Analysis vs. Event Tree Analysis

| Feature | Fault Tree Analysis (FTA) | Event Tree Analysis (ETA) |

| Approach | Top-down approach | Bottom-up approach |

| Focus | Identifying causes leading to a single undesired event (top event) | Examining possible outcomes following an initiating event |

| Starting Point | Begins with a predefined undesirable event (top event) | Begins with an initiating event |

| Objective | Determine the root causes of the top event | Explore the potential consequences of the initiating event |

| Logic Gates | Uses AND, OR gates to model logical relationships | Uses a branching structure to model different outcome paths |

| Diagram Orientation | Tree structure with branches pointing downward | Tree structure with branches expanding outward |

| Primary Use | Risk analysis and identifying critical failure paths | Evaluating system responses and identifying potential consequences |

| Qualitative Analysis | Identifies minimal cut sets and failure paths | Identifies different outcome sequences |

| Quantitative Analysis | Calculates the probability of the top event | Calculates the probability of different outcomes |

| Event Representation | Events represented by symbols (basic event, undeveloped event) | Events represented by branches and nodes |

| Application | Engineering, aerospace, nuclear safety, chemical processes | Safety analysis, emergency response planning, reliability analysis |

| Strengths | Detailed analysis of causes, helps identify root causes | Comprehensive outcome analysis, useful for emergency planning |

| Limitations | Complex and time-consuming for large systems, data-dependent | Can become complex with many branches, dependent on initial event |

| Example Use Case | Analyzing the causes of a reactor meltdown | Exploring possible outcomes of a power plant failure |

| Result Presentation | Fault tree diagram with logical gates and events | Event tree diagram with branching paths and outcomes |

Advantages of FTA

- Comprehensive Analysis: FTA provides a detailed, systematic analysis of all possible causes of a top event, helping identify critical vulnerabilities in a system.

- Qualitative and Quantitative Insights: It offers both qualitative descriptions of potential failure paths and quantitative estimates of failure probabilities.

- Risk Mitigation: The analysis can guide risk mitigation efforts by identifying the most critical failure modes and their causes.

Limitations of FTA

- Complexity: Constructing fault trees for large systems can be tedious and complex.

- Data Dependency: Quantitative analysis relies heavily on the availability and accuracy of failure data.

- Subjectivity: Determining the level of detail and completeness of the fault tree often involves subjective decisions.

Applications of FTA

FTA is used in various fields, including:

- Aerospace: Assessing the safety of missile and spacecraft systems.

- Nuclear Engineering: Evaluating the safety of nuclear reactors.

- Chemical Process Industry: Analyzing the potential causes of chemical plant accidents.

- Automotive Industry: Identifying failure modes in automotive systems.

Final Words

Fault Tree Analysis is a powerful tool for identifying and analyzing potential causes of system failures. By systematically breaking down the events leading to a top event, FTA helps engineers and safety professionals understand the interactions and dependencies within a system.

Despite its complexity, the insights gained from FTA are invaluable for improving system reliability and safety.