Center points serve as fundamental concepts across mathematics, geometry, engineering, and everyday applications. Whether you’re designing architectural layouts, solving geometric problems, or planning urban developments, understanding center points becomes essential for accurate calculations and optimal positioning.

This comprehensive guide explores everything you need to know about center points, their applications, and practical implementations.

Table of contents

What Are Center Points and Why Do They Matter?

Centre points represent the exact middle or focal position of geometric shapes, objects, or coordinate systems. Moreover, these mathematical concepts provide reference points that help determine balance, symmetry, and optimal positioning in various applications. Consequently, professionals across multiple industries rely on center points for precise measurements and strategic planning.

The significance of center points extends beyond theoretical mathematics. In fact, engineers use center points for structural calculations, architects implement them for balanced designs, and urban planners utilize them for efficient city layouts. Furthermore, understanding center points enables better decision-making in spatial relationships and geometric problem-solving.

Public, Onsite, Virtual, and Online Six Sigma Certification Training!

- We are accredited by the IASSC.

- Live Public Training at 52 Sites.

- Live Virtual Training.

- Onsite Training (at your organization).

- Interactive Online (self-paced) training,

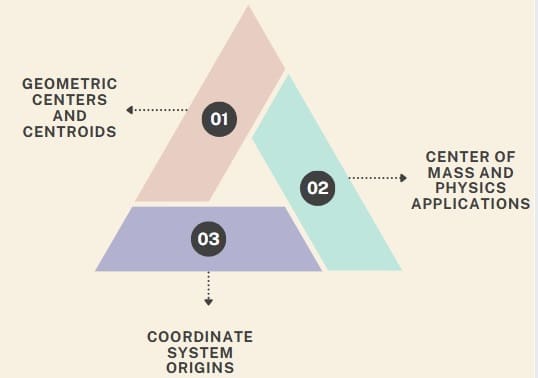

Types of Center Points in Mathematics and Geometry

Geometric Centers and Centroids

Geometric centers, also known as centroids, represent the average position of all points within a shape. Additionally, these points provide crucial information about the shape’s balance and distribution. For triangles, the centroid occurs at the intersection of the three medians, while rectangles have their geometric centers at the intersection of diagonals.

Calculating centroids involves averaging the coordinates of all vertices or points within the shape. Subsequently, this mathematical approach ensures accurate positioning for engineering applications and design projects. Moreover, centroids play vital roles in determining moments of inertia and stress distributions in mechanical engineering.

Center of Mass and Physics Applications

The center of mass represents the point where an object’s mass concentrates theoretically. Similarly to geometric centers, the center of mass provides essential information for balance and stability calculations. Consequently, engineers and physicists rely on these calculations for designing stable structures and predicting object behavior.

In practical applications, the center of mass determines how objects rotate, balance, and respond to external forces. Furthermore, understanding center of mass principles helps in vehicle design, spacecraft navigation, and robotics applications. Therefore, mastering these concepts becomes crucial for anyone working in physics-related fields.

Coordinate System Origins

Coordinate system origins serve as reference points for measuring distances and positions. Additionally, these center points establish the foundation for mathematical calculations and spatial relationships. Whether using Cartesian, polar, or spherical coordinate systems, the origin point remains essential for accurate measurements.

Selecting appropriate coordinate system origins can significantly simplify calculations and improve accuracy. Moreover, strategic placement of these reference points enhances problem-solving efficiency and reduces computational complexity. Consequently, understanding coordinate system principles becomes valuable for mathematics and engineering applications.

Practical Applications of Center Points

Architectural and Construction Uses

Architects frequently utilize center points when designing balanced and aesthetically pleasing structures. Furthermore, these reference points help create symmetrical layouts, determine load-bearing positions, and optimize space utilization. Additionally, construction professionals rely on center points for accurate measurements and precise positioning of structural elements.

In building design, center points guide the placement of columns, beams, and other structural components. Similarly, interior designers use these concepts for furniture arrangement and room layout optimization. Therefore, understanding center points enhances both functional and aesthetic aspects of architectural projects.

Urban Planning and City Development

Urban planners implement center points when designing efficient city layouts and transportation networks. Moreover, these reference points help optimize traffic flow, determine optimal locations for public services, and create balanced neighborhood developments. Additionally, center points assist in calculating distances between key facilities and ensuring equitable resource distribution.

City development projects benefit from strategic center point placement for maximum efficiency and accessibility. Furthermore, these mathematical concepts support sustainable urban growth and improved quality of life for residents. Consequently, understanding center points becomes essential for modern urban planning initiatives.

Engineering and Manufacturing Applications

Manufacturing industries rely heavily on center points for precision machining, quality control, and product design. Additionally, these reference points ensure consistent production standards and accurate measurements throughout manufacturing processes. Moreover, engineers use center points for calculating tolerances, determining assembly positions, and optimizing product performance.

In mechanical engineering, center points help design rotating machinery, balance systems, and predict stress distributions. Similarly, electrical engineers utilize these concepts for circuit layout optimization and component positioning. Therefore, center points remain fundamental to successful engineering projects across various disciplines.

Also Read: Principal Component Analysis (PCA): Simplify Data & Find Key Insights

How to Calculate Center Points: Step-by-Step Methods

Finding Centers of Simple Shapes

Calculating center points for basic geometric shapes follows straightforward mathematical procedures. First, identify all vertices or boundary points of the shape. Next, apply the appropriate formula based on the shape type. Finally, verify your calculations through alternative methods or geometric construction.

For rectangles and squares, the center point occurs at the intersection of diagonals. Meanwhile, circular center points coincide with the geometric center of the circle. Additionally, triangular centroids require calculating the average of all three vertex coordinates, ensuring accurate results for further applications.

Advanced Calculation Techniques

Complex shapes require more sophisticated approaches for center point determination. Initially, divide irregular shapes into simpler geometric components. Subsequently, calculate individual center points for each component. Finally, determine the overall center point using weighted average methods based on area or mass distribution.

Computer-aided design software often automates these calculations for complex geometries. However, understanding the underlying mathematical principles remains important for verification and troubleshooting purposes. Moreover, manual calculation skills provide valuable backup capabilities when technology fails or becomes unavailable.

Using Technology and Software Tools

Modern technology offers numerous tools for center point calculations and verification. CAD software, mathematical applications, and specialized engineering programs streamline these processes significantly. Furthermore, these tools provide visual representations that enhance understanding and reduce calculation errors.

Online calculators and mobile applications make center point calculations accessible for quick reference and field applications. Additionally, programming languages like Python and MATLAB offer powerful capabilities for complex center point analysis and batch processing. Therefore, combining traditional mathematical knowledge with modern technology optimizes efficiency and accuracy.

Common Mistakes and How to Avoid Them

Calculation Errors and Prevention

Calculation mistakes often occur when working with center points, particularly in complex geometric scenarios. First, always double-check coordinate values and ensure consistent units throughout calculations. Next, verify results using alternative calculation methods or geometric construction techniques. Finally, use estimation techniques to confirm that calculated results appear reasonable.

Unit conversion errors frequently cause significant problems in center point calculations. Therefore, establish clear unit standards at the project beginning and maintain consistency throughout all calculations. Additionally, create systematic checking procedures to catch and correct errors before they impact final results.

Conceptual Misunderstandings

Many people confuse different types of center points, leading to inappropriate applications and incorrect results. Consequently, clearly distinguish between geometric centers, centers of mass, and coordinate origins before beginning calculations. Moreover, understand when each type applies to specific situations and applications.

Visual representation helps prevent conceptual errors and improves understanding of center point relationships. Furthermore, practicing with various examples reinforces correct application principles and builds confidence in problem-solving abilities. Therefore, invest time in developing solid conceptual foundations before tackling complex applications.

Also Read: Human-Centred Designs

Center Points in Modern Technology and Innovation

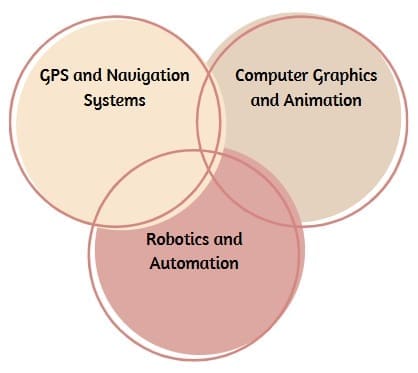

GPS and Navigation Systems

Global positioning systems rely heavily on center point calculations for accurate location determination and navigation guidance. Additionally, these systems use multiple reference points to triangulate positions and provide real-time location updates. Moreover, center point algorithms optimize route planning and improve navigation efficiency for various transportation modes.

Smartphone applications utilize center point concepts for location-based services, mapping functions, and augmented reality features. Furthermore, autonomous vehicles depend on precise center point calculations for safe navigation and obstacle avoidance. Consequently, understanding these concepts becomes increasingly important as technology continues advancing.

Computer Graphics and Animation

Computer graphics applications extensively use centre points for object positioning, rotation calculations, and animation sequences. Additionally, these reference points enable realistic physics simulations and improve visual quality in games and movies. Moreover, centre point algorithms optimize rendering performance and reduce computational requirements.

3D modeling software relies on centre points for object manipulation, transformation operations, and scene composition. Furthermore, animation systems use these concepts for character movement, camera positioning, and special effects creation. Therefore, centre points remain fundamental to modern digital content creation and entertainment industries.

Robotics and Automation

Robotic systems utilize centre points for precise movement control, object manipulation, and navigation tasks. Additionally, these reference points help robots understand spatial relationships and interact safely with their environment. Moreover, centre point calculations enable accurate positioning for manufacturing automation and assembly operations.

Artificial intelligence systems incorporate centre point concepts for pattern recognition, spatial analysis, and decision-making processes. Furthermore, machine learning algorithms use these mathematical foundations for improving performance and accuracy in various applications. Consequently, centre points bridge traditional mathematics with cutting-edge technology development.

Industry-Specific Applications and Case Studies

Healthcare and Medical Imaging

Medical imaging technologies extensively utilize centre points for accurate diagnosis and treatment planning. CT scans, MRI images, and X-rays rely on precise reference points for image alignment and measurement calculations. Additionally, surgical planning benefits from centre point analysis for optimal procedure execution and patient safety.

Radiation therapy treatments require exact centre point calculations to target tumors while protecting healthy tissue. Furthermore, medical device design incorporates these concepts for improved functionality and patient comfort. Therefore, understanding centre points contributes significantly to advancing healthcare technology and patient outcomes.

Aerospace and Aviation

Aircraft design heavily depends on centre point calculations for balance, stability, and performance optimization. Additionally, center of gravity determinations ensure safe flight characteristics and fuel efficiency. Moreover, spacecraft navigation systems rely on precise centre point calculations for trajectory planning and orbital mechanics.

Airport planning utilizes centre points for runway positioning, terminal layout optimization, and air traffic management systems. Furthermore, these concepts support flight path calculations and collision avoidance systems. Consequently, centre points play crucial roles in aviation safety and operational efficiency.

Best Practices for Working with Centre Points

Documentation and Record Keeping

Maintaining detailed documentation of centre point calculations ensures accuracy and enables future reference. Additionally, clear records facilitate project collaboration and help identify potential errors or improvements. Moreover, standardized documentation formats improve communication between team members and reduce misunderstandings.

Version control systems help track changes in centre point calculations and maintain calculation history. Furthermore, backup procedures protect important calculation data from loss or corruption. Therefore, establishing robust documentation practices supports successful project completion and knowledge preservation.

Quality Assurance and Verification

Implementing systematic verification procedures helps ensure centre point calculation accuracy and reliability. Additionally, peer review processes catch errors that individual calculators might miss. Moreover, using multiple calculation methods provides confidence in final results and identifies potential problems.

Testing calculated centre points with physical models or simulations validates theoretical results and improves understanding. Furthermore, comparing results with established benchmarks or industry standards ensures compliance and accuracy. Consequently, quality assurance practices enhance project success and professional credibility.

Final Words

Centre points are crucial in various fields as they represent balance, symmetry, and stability. In geometry, they help define the midpoint or central location of shapes. In statistics and experimental design, centre points enhance accuracy and reveal curvature or non-linearity. Their applications span design, architecture, data analysis, and engineering.

By providing a reference or equilibrium, centre points aid in analysis, decision-making, and optimization. Understanding and utilizing centre points leads to more precise and efficient outcomes across disciplines.

Frequently Asked Questions About Centre Points

What is the difference between a centre point and a centroid?

Centre points refer to any central reference position, while centroids specifically represent the geometric center of a shape based on area distribution. Centroids are a type of centre point used primarily in geometry and engineering applications.

How do I find the centre point of an irregular shape?

Break the irregular shape into simpler geometric components, calculate individual centre points for each component, then determine the overall centre point using weighted averages based on area or mass distribution.

Can centre points exist outside the original shape?

Yes, centre points can lie outside the original shape, particularly for concave shapes or objects with irregular mass distribution. This commonly occurs in engineering applications involving complex geometries.

What software tools are best for centre point calculations?

CAD software like AutoCAD, SolidWorks, and mathematical programs like MATLAB or Python offer excellent capabilities for centre point calculations. Choose tools based on your specific application requirements and complexity needs.

Why are centre points important in engineering?

Centre points provide essential reference positions for balance calculations, stress analysis, structural design, and manufacturing processes. They ensure accuracy, optimize performance, and support safe, efficient engineering solutions.