Process intelligence is a combination of task analysis and intuitive thinking. Combining process mining and business concepts can deliver insights about end-to-end systems. Process Intelligence (PI) provides suggestions for automation as well as clear ideas for improvement.

If a company needs to see the big picture or dive into the details in great detail, Process Intelligence is a new way of looking at data. The best of both people and technology.

It’s not enough to produce goods in today’s rapid manufacturing environment. You also need to improve processes for efficiency and cost reduction. It transforms the way manufacturers analyze their operations and improve them.

What is Process Intelligence (PI)?

Process intelligence is a systematic analysis of manufacturing processes to gain insight into their efficiency, performances, and areas for improvement. It involves gathering, monitoring and analyzing the data generated during all stages of production.

It is used to improve operational efficiency or remove constraints by using advanced analytics and data visualization tools. Further, it acts as a catalyst in business process redesign.

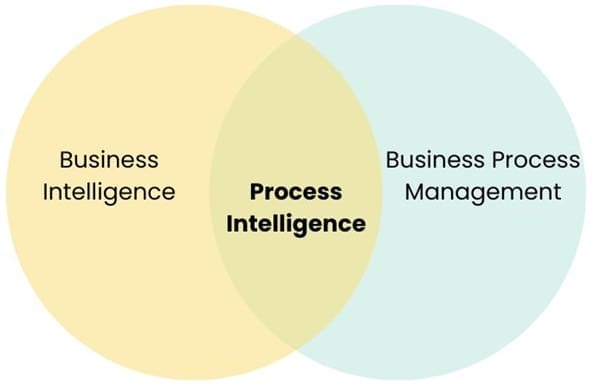

Process intelligence is the application of business intelligence technologies and strategies to business process management. It is a new approach that can transform the way organizations operate. It allows them to get unprecedented insight into their processes and improve continuously.

Business Process Intelligence is an advanced analytical method that uses data mining, modelling and automation to improve and enhance processes. It goes beyond business intelligence and provides refined insights into processes as well as automated process analysis capabilities.

Definition of Process Intelligence

Process intelligence is an integrated methodology that combines task mining, process mining and business intelligence. This will provide a comprehensive view of the operational processes of the organization.

It is a powerful tool that can transform raw data from processes into insights and actions. This will result in continuous improvement, increased operational efficiency, and a competitive advantage for an organization.

This covers the systematic collection of data, its analysis and interpretation, and its application to business processes. Therefore, it showcases valuable insights about task durations and resource usage. Also, it provides details on process variations and deviations from protocols.

You can edit and identify process functions by using discovery, analysis, and process optimization. It allows you to scale automation faster, by identifying inefficiencies.

PI is the key to enterprise optimization, digital transformation, and business process automation. It delivers a continuous flow of accurate and unbiased data that helps highlight inefficiencies and streamline processes.

How does Process Intelligence work?

PI is a technology that combines sensors, IoT devices and data analytics with machine learning algorithms to collect and interpret data within the manufacturing environment. These data are then visualized using intuitive dashboards and reporting, giving manufacturers actionable insights in real-time.

What is the process of data collection?

Process Intelligence starts with the collection of data from different sources such as IT systems and databases. Employee input is also taken into consideration. The information collected is used to build a comprehensive picture of the current state of processes within an organization.

Method 1: Process Mining

Process mining involves the extraction of event logs from IT systems, which are then utilized to reconstruct process models. This enables companies to gain insights into their processes, determine their flow, highlight constraints, and uncover areas for improvement.

Method 2: Task Mining

Task mining uses technology that tracks user-generated data such as keystrokes, screen recording and mouse clicks to analyze it. This allows organizations to understand how their employees perform tasks, identify best practices, and pinpoint areas that may need additional training or assistance.

Method 3: Work API

Work API combines elements from task mining and process mining to provide a quicker and less intrusive way to collect data about processes from the user interface, or metadata of business applications.

Process Intelligence Vs Business Intelligence

Business intelligence (BI) utilizes technology-driven methods to analyze and transform data into actionable insights, empowering rational decision-making. It aims to thoroughly grasp an organization’s performance, market trends, and customer behaviour.

| Basis | Process Intelligence | Business Intelligence |

| Focus | Analysis and optimization of business processes | Overall view of company’s performance, market trends, and customer behaviors. |

| Application | Analyzing processes within the organization (e.g., supply chain management, human resources, customer service) | Incorporating various data types including financial data and sales data |

| Data Types | Primarily operational data related to business processes | Includes structured and unstructured data from internal and external sources |

| Capabilities | Workflow automation, real-time monitoring, process optimization | Descriptive, prescriptive, predictive, and diagnostic analytics capabilities |

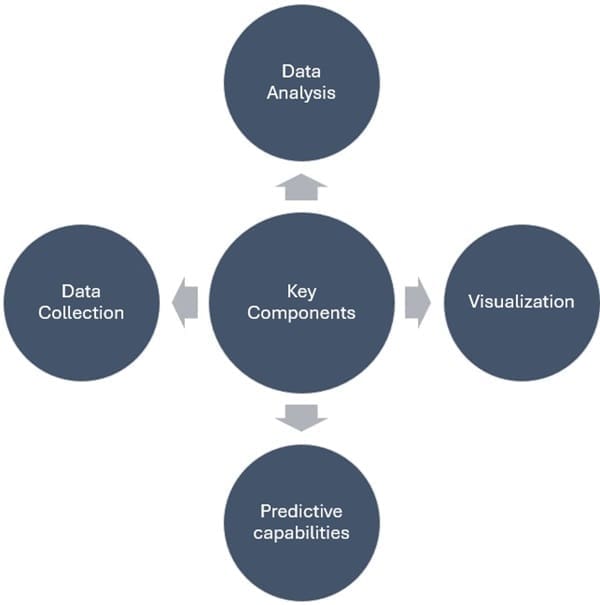

Key Components

- Data Collection: The first step in achieving PI is to collect data at different points of the manufacturing process. Information on equipment performance, material usage and production rates are included.

- Data Analysis: On the collection of data, advanced analytical techniques are implemented to discover patterns, trends and anomalies. This analysis helps to identify areas of improvement to increase efficiency and productivity.

- Visualization: Data analysis insights are presented by way of user-friendly visualizations such as charts, graphs, and heat maps. It enables stakeholders to grasp the current status and make well-informed decisions swiftly.

- Predictive capabilities: Process intelligence goes beyond simply analyzing past data. By using predictive analytics, manufacturers can anticipate future outcomes and proactively tackle potential issues before they arise. With machine learning algorithms, manufacturers optimize maintenance, scheduling, and resource allocation. This will enhance throughput while reducing downtime.

Process Intelligence Tools and Software

Selecting the right tools and software is essential to implementing process intelligence in an organization.

The market for process intelligence offers a variety of options. These options span from comprehensive suites to specialized solutions designed specifically to cater to unique requirements.

It is important to evaluate these tools for factors like integration with existing systems and scalability. Also, consider data security, privacy and advanced analytics.

Moreover, companies should evaluate the level of training and ongoing support offered by vendors, alongside their dedication to long-term innovation and development.

Benefits of Process Intelligence in Manufacturing

- Efficiency Improvement: Identifies bottlenecks and inefficiencies, and optimizes resource usage, leading to increased productivity and reduced lead times.

- Quality Monitoring: Allows real-time monitoring of key metrics, enabling detection of deviations from desired standards and prompt corrective actions to maintain product quality.

- Cost Reduction: Reduces production costs by minimizing downtime and optimizing inventory management.

- Agility and Adaptability: Provides insights for agile decision-making and adjusting operations to meet changes in market conditions and customer demands.

- Compliance and Risk Management: Maintains detailed logs of production activities and performance metrics, ensuring compliance with regulatory requirements and minimizing operational risks.

Also See: 5S Housekeeping – What is it?

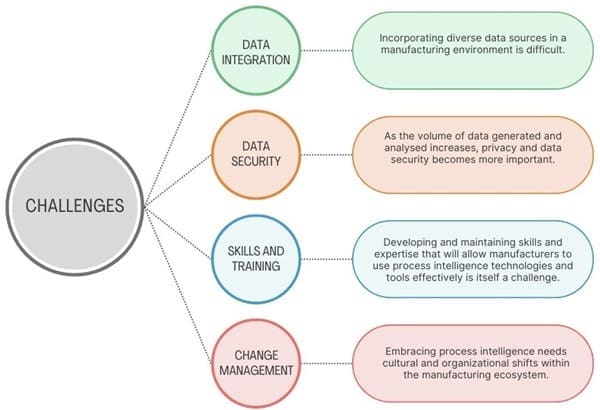

Challenges

- Data Integration: Incorporating diverse data sources in a manufacturing environment is difficult. For a smooth collection of data, manufacturers must ensure that different devices and systems are compatible and interoperable.

- Data Security: As the volume of data generated and analysed increases, privacy and data security becomes more important. Manufacturers need to implement strong security measures to protect sensitive data and prevent unauthorized access.

- Skills and Training: Developing and maintaining skills and expertise that will allow manufacturers to use process intelligence technologies and tools effectively is itself a challenge. For effective implementation of process intelligence solutions, it is important to invest in employee training and development.

- Change Management: Embracing process intelligence needs cultural and organizational shifts within the manufacturing ecosystem. It is important for manufacturers to effectively communicate the advantages of process intelligence to both employees and stakeholders. This will build a culture focusing on data-driven decision-making.

Difference Between Process Mining and Process Intelligence

| Basis | Process Mining | Process Intelligence |

| Scope | Analyzes historical data to visualize and understand existing processes. | Offers insights into both historical and real-time processes for ongoing monitoring and optimization. |

| Focus | Primarily focuses on discovering and mapping existing processes. | Combines task mining, process mining, and business intelligence metrics to provide deep insights and real-time monitoring. |

| Time Frame | Typically conducts a retrospective analysis of past processes. | Provides real-time monitoring and notification of errors and deviations as processes unfold. |

| Connectivity to Data Sources | May have limitations in connecting to certain data sources or complex processes. | Capable of analyzing diverse data sources and complex processes effectively. |

| Notification of Errors and Deviations | Lacks real-time monitoring capabilities, thus cannot notify process owners of errors as they occur. | Lacks real-time monitoring capabilities, and thus cannot notify process owners of errors as they occur. |

Final Words

Process intelligence is an effective tool for manufacturers that allows them to optimize their processes and improve continuously. Data analytics and advanced technology can help manufacturers improve efficiency, quality and agility.

This will give them a competitive advantage in the rapidly changing marketplace. Process intelligence is not a choice, but a necessity if manufacturers want to succeed in the digital age.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.