Table of contents

5S Housekeeping – What is it?

The 5S system has been proven to be a great way to improve any workplace with lean 5s principles. It helps identify inefficiencies and gives an outline of how to eliminate them. This will allow tasks to be completed faster and with fewer errors. Although the 5S concepts are simple, they have been effective throughout history. The lean 5S principles are so easy that many people simply call it the 5S Housekeeping checklist, you can find various examples of this.

5S isn’t a revolutionary approach to workplace management. It is a process that combines a lot of common sense ideas to improve any facility. When 5S is used correctly, it will maintain improvement over time. This is unlike other process improvement methods. To avoid falling back into old bad habits, you can engage in ‘housekeeping’.

5s activities aim to qualitatively alter how people think and act, and to improve the quality of equipment maintenance and work environments. Everyone involved in 5s activities should be able to clearly understand and put into writing the 5S’s and their meanings for each company and workplace. It is also helpful to create slogans, as 5s activities should be done with determination and concerted effort. It is difficult to implement the rules if they are not very practical. Five action items were taken by the Ark with various types of persuasion. These aspects should be a part of the daily routine for individuals.

Why Housekeeping?

People call the 5S housekeeping checklist because it must be done regularly. The 5th S is about going back and making certain that the strides made in the previous S’s continue into the future.

A home that isn’t maintained properly will eventually become disorganized and dirty. For example, a facility that does not follow the 5S principles will lose any progress made. In any industry, employees will take shortcuts, and eventually, efficiency will drop and waste will be reintroduced.

Companies that engage in 5S housekeeping will not only be able to maintain the improvements made, but also continue to make further improvements. Lean 5S principles can be used as a complement to any workplace improvement program or as a standalone program.

We need to be able to organize and run a factory efficiently and effectively. This is the foundation for Lean manufacturing tools that we use to implement Lean housekeeping. Practical 5S.

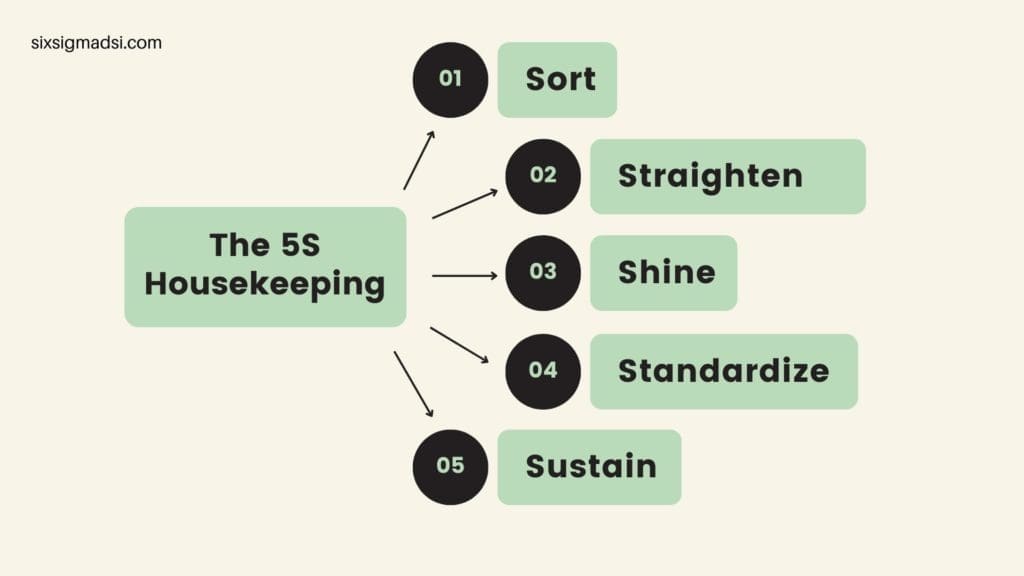

The 5S system is a systematic way to do good housekeeping. Although there are many ways to interpret the original Toyota definitions, the basic principles behind the stages remain the same. We will now examine the five S’s.

You can start 5S, or revitalize your body. Choose an area and give yourself at least 3 hours to complete the first three stages.

1. Sort – sort through all your stuff. Throw away any rubbish and archive anything you might need. Then, determine what you need on a daily or weekly basis. All other items must be removed. This is not a place where sentiment can play a role. It’s a manufacturing environment.

2. Set in Order – Take the items that you use in the area daily or weekly and locate the best homes. Label, mark locations, color code – Make it clear for anyone who enters the area where they should be.

3. Shine and Clean – After you have set a place for each item, wipe it down and make sure it is in good working order. Broken items should be repaired. You should allow more time to clean up if your work area is very dirty.

These three steps will help you get started on the path to improving your factory’s visual appeal. If factories look better, people feel more comfortable working there.

Maintaining this new level of organization is the challenge

Here is where “Standardization” and “Sustaining”, come into play. We will explore this below.

This is the easiest part of 5S. Once you start, it is easy to get started. We are familiar with how to organize and tidy our homes, cars, garages, and for tax returns. However, some people are better than others. The challenge is to keep it clean and not let it slip back. Here are the final two “S’s.

4. Standardization – The new layout and standard of cleanliness are our new standards for each area. Display photos of the area and talk about 5S activities in your toolbox talks, and daily meetings, and share ideas throughout the factory. This will help you create 5S standards for the factory and ensure consistency.

5. Sustain – If the first four S’s are done well, it becomes easier to maintain cleanliness and origination. Each person in an area will know where things go and where they can be returned at the end of a shift or at the job’s end. For example, simple audits can be used to track our progress in maintaining our 5S baseline every week and also to identify areas for improvement.

No matter where you are in the Lean Manufacturing implementation process, 5S is a great housekeeping tool that will help you stay on track and involve everyone in your business. You can always go back to Sorting or Setting up orders if you get lost. This is the basis of your Lean production system. You can make it work.

The 5S housekeeping checklist

Japan invented the 5S. It stands for five Japanese words that begin with the letter “S”: seiri (seiton), season, seiketsu, and shitsuke. To preserve the 5S acronym, sort, set(in position), shine, standardize, sustain- in English usage, an equivalent set of five “Swords” in English was adopted.

1. Seiri (sort).

2. Seiton (straighten or streamline)

3. Seiso (shine)

4. Seiketsu (standardized)

5. Shitsuke (sustain)

5S Actions Checklist

The following example list of actions is needed to make sure 5S is incorporated into the DNA of an organization.

1. Arrange training for employees in 5S technique. Provide leaflets/easy-to-read booklets about 5S practices to all employees.

2. Practice pick up components/papers/rubbish and promote friendly competition & competitive benchmarking among the departments for 5S.

Observe the paper destruction day, which is usually on the 15th/16th of each month after each quarter.

3. Practice handling emergencies and conduct fire drills.

4. Retire equipment after the economic retentive period.

5. Collaborate on 5S-specific projects.

Ensure that all employees arrive at work in uniform and are wearing safety shoes.

6. All must focus on 5S for a brief time (e.g., 10 minutes). One day to make sure everything is in order, the next day to make sure there isn’t any oil or debris.

air leaks.

7. To practice 5S, mark 5 minutes at the end or beginning of each day.

8. Visuals can be used to draw attention and create a competitive point.

9. Audit 5-S housekeeping, and follow up for non-conformances.

10. Ensure that employees follow the established standard operating procedures and display correct work instructions in the office and shop.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.