Table of contents

How to Complete the Six Sigma SIPOC Diagram

This article “What is a SIPOC Diagram” is the first in a four-part series to show you “How to Complete a Six Sigma Root Cause Analysis”. The series covers four tools:

- The SIPOC(R) Diagram

- The Input (or Variables) Map

- The C&E Matrix

- The FMEA (Failure Modes and Effects Analysis)

Watch this video to get a quick introduction to the SIPOC Diagram:

What is SIPOC (or COPIS)?

SIPOC (or COPIS) diagrams show the operation’s suppliers, inputs, processes, outputs, customers, and other information. These elements are used to define the boundaries of a process at elevated levels. This diagram gives decision-makers crucial information without getting too detailed.

SIPOC (or COPIS) streamlines workflows and helps identify and solve problems. It also eliminates wasteful activities. SIPOC does this by focusing on process visualization and limiting information to what is necessary for management to identify the areas that require improvement.

SIPOC (or COPIS) was developed by the Total Quality Management movement of the 1980s. LEAN management practitioners and Lean Six Sigma professionals then adopted it. It usually applies to the “measure” phase of a DMAIC exercise.

What is the purpose of the SIPOC (or COPIS) Diagram?

Your business’ success is dependent on many factors. You should make every effort to ensure smoother operations and better customer satisfaction. SIPOC (or COPIS) will help you see the direct correlation between what customers ask for and what suppliers give you. It also shows you how to marry these two elements in your business. You will find the answers to such questions as:

- Are you satisfied with the quality of your suppliers?

- Do you have the correct translations of customer needs into goods or services?

- Are you and your team taking the fastest route to creating the product?

- Are you able to identify your customer?

SIPOC (or COPIS) diagrams can also be helpful in introducing new members to a project. Also useful for planning new business ideas.

What is the History of SIPOC Diagrams?

Origins of the SIPOC diagram can be traced back as far as the late 1980s. It was used in the Six Sigma model for continuous process improvement and total quality management (TQM). This technique is used in the DMAIC improvement phase’s definition phase, where project goals, objectives, scope, and time frames are clearly defined. SIPOC can also play a complementing role in LEAN manufacturing programs and business process improvement programs.

Why are SIPOC diagrams important?

SIPOC diagrams, a proven quality-management technique used in Six Sigma project management and other process improvement models, are a well-known method. This diagram can be used to identify the causes of process variation. This diagram can be used for measuring and controlling these variations to achieve a more predictable and stable process.

SIPOC diagrams can be used to analyze and improve business processes. They are simple to use and employ less specific language. This makes them easy to apply to any business context. They can be used to onboard new members of a team or fill in for existing members of a project.

SIPOC diagrams can be used to identify the process input specifications and to determine who will supply them. This helps to avoid any misunderstandings. It helps identify customers and their requirements.

What is the definition of SIPOC?

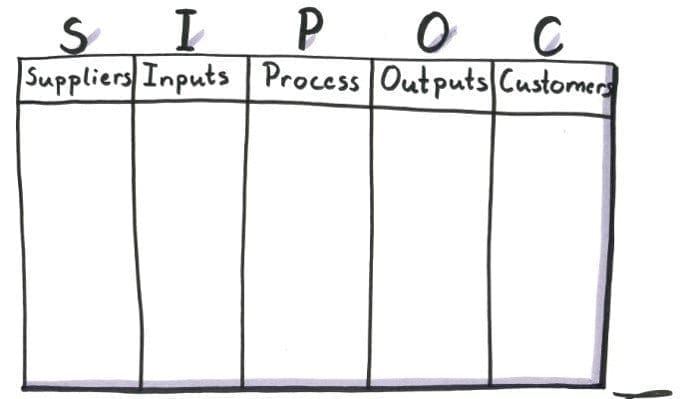

SIPOC (or COPIS) is a diagram that represents all inputs and outputs in a process. Below are the components of the acronym.

Customers

Learn about the customer and what they want. A customer is anyone who receives an output from the process. There can be both internal and external customers. You should also determine the impact that the customer has on your process.

The LEAN customer focus aligns with the value-based approach. We think about value as what the customer will pay. This is where the LEAN Six Sigma concept, the voice, and the customer are essential. It reflects the client’s needs. You can equip yourself to meet customer-specific and validated needs by correctly identifying them.

Outputs

Outputs are the product of the process and should respond to customer needs. Ideally, they should reflect the customer’s value. These outputs are typically a list of products, delivered services or completed actions.

The Process

It’s a list of all the important steps in the process. The SIPOC diagram gives a visual overview of the process, including the beginning and endpoints. You should only list the most important steps, not more than 10, and don’t go into detail.

Inputs

Suppliers provide inputs in the form of materials, which can be either physical goods or information. This is essential for a company to function. Make sure you gather all stakeholders to ensure accuracy in your input as well as the whole of SIPOC.

Suppliers

They provide input to the process. The diagram should be brief so that you can focus on suppliers that have an immediate impact on the outputs of the process.

What are the benefits of SIPOC (or COPIS)?

SIPOC can be used to not only bring in new people to a process but also to help align the mutual understanding of the project’s goals. Both employees and stakeholders can benefit from it. Below are some of the key benefits of SIPOC.

- This helps to clarify input and output requirements.

- Facilitates problem-solving within the process.

- This provides a high-level overview of projects for strategic management.

- SIPOC provides transparency and alignment throughout the organization of the process.

- This can be used to create process documentation or templates for projects and processes.

- This helps to identify suppliers and customers.

- SIPOC can also be used for training purposes during onboarding.

What are the disadvantages of SIPOC?

SIPOC (or COPIS) diagrams have their drawbacks, but they are simple. It increases transparency within the organization but is not sufficient to resolve process-related problems on its own.

- SIPOC is a straightforward way to map process flows.

- SIPOC diagrams may not be sufficient to solve process problems.

- It is best to be complemented with other tools.

How to create a SIPOC (or COPIS) diagram

SIPOC diagrams are tables that document the inputs as well as outputs of a process. These diagrams can be made by following seven steps.

Select a process

First, choose a business process you think would benefit from charting in SIPOC. The key players in the process can then be assembled into a team.

Define the process

The “P” section is usually an overview of the business. Each step consists of an action or a subject. This could be a flowchart or the starting and endpoints of the process.

Identify the outputs

This section usually uses nouns and has neutral tones. You can input and output anything, including materials, products, information, or services.

Identify your customer

These are people who will benefit from or receive the outputs. Customers can be either coworkers, board members, or other stakeholders.

Identify the inputs

This section lists the resources required for the process’s proper functioning. Like outputs and inputs, it is important that only the most critical, fundamental inputs are listed.

Identify the suppliers

This section lists all suppliers that are associated with the inputs. Anybody who has an immediate impact on the outputs is a supplier.

Share the diagram

Once the diagram has been created, you should share it with all relevant stakeholders. Validate the diagram before continuing with the process.

What does SIPOC (or COPIS) do for a Lean Six Sigma Project?

Lean Six Sigma uses the SIPOC diagram in the definition phase of Lean Six Sigma project administration. It is one of the most used sets of tools and techniques to improve process performance. Lean Six Sigma focuses on improving the process by identifying and eliminating the root causes of the defects. It also minimizes variability. These are the points where they intersect and complement each other.

SIPOC diagrams provide visual representations of business processes mapping. These diagrams provide a concise and clear overview of the inputs, outputs, and customers of a business process. The SIPOC tool helps Six Sigma achieve its key objective, which is to identify and reduce variation. You will be able to map a process using a SIPOC diagram and gain a better understanding of how each item would affect the outputs (process benefits).

SIPOC diagrams are useful in measuring and controlling variations by helping to identify root causes. SIPOC diagrams can be used to identify the root causes of process variation and provide valuable insight into potential improvement areas. You will eventually reduce process variation, which in turn will lower outputs’ variability and make your process more predictable and stable – one key Six Sigma assertion.

What Industries Can Use SIPOC (or COPIS)

SIPOC diagrams are a complete process improvement technique. They capture a process, along with its inputs, and outputs, on one map that is accessible to all. The business mapping model is easily used by any industry, company, department, or individual. Below are some of the most popular uses of the SIPOC visualization.

The SIPOC or (COPIS) is one of the most important tools in a Lean and/or Six Sigma project. This tool will help a team identify whether they have focused on the right process. The SIPOC will also help the team to understand who their customers are and what their requirements are.

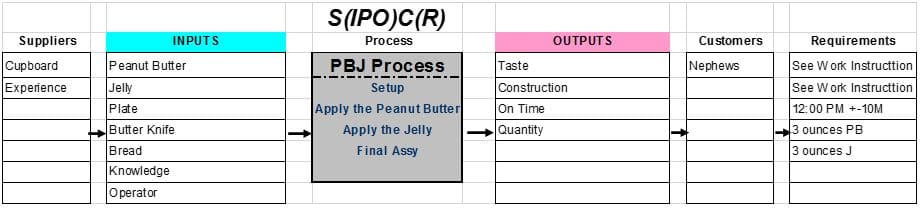

The SIPOC helps us break down our process into External Inputs and their Suppliers; Process Steps; and Outputs, Customers, and their Requirements. This diagram allows us to see the process from a 30,000-foot view.

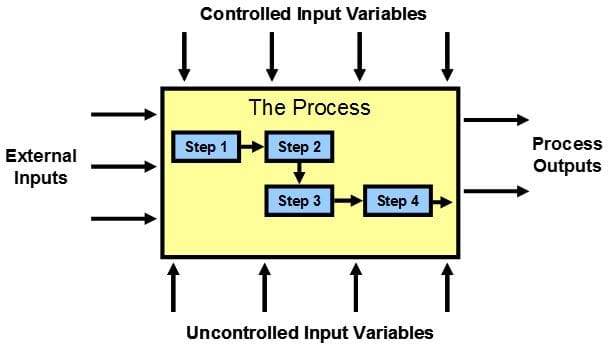

The picture below is a basic diagram to understand the SIPOC:

SIPOC Example

I like to use the example of mowing a lawn to describe the diagram above. The Scope of “The Process” is inside of the box. The “External Inputs” (left of the box) are those things that must be fed to The Process for The Process to work.

Let’s say that the Scope of The Process of mowing the lawn starts with: You are standing behind the lawnmower, it is running and ready to mow the lawn. What must be fed to The Process for the Process to Work?

- Someone (or Something) to push the lawnmower

- A Lawnmower

- Knowledge of how to work the lawnmower

- Proper Weather

Why is it important to understand our Internal Inputs? Our focus during the Lean and Six Sigma Project will be on the “P” in the SIPOC. What if we are focused on the wrong process? By understanding our “External Inputs”, we might find one or more “External Inputs” have a significant effect on our “Process Output”.

By not addressing that input, we may not make a significant enough improvement to our “Process Output”. One of the most powerful aspects of a SIPOC is to help a project team determine if they have the right focus.

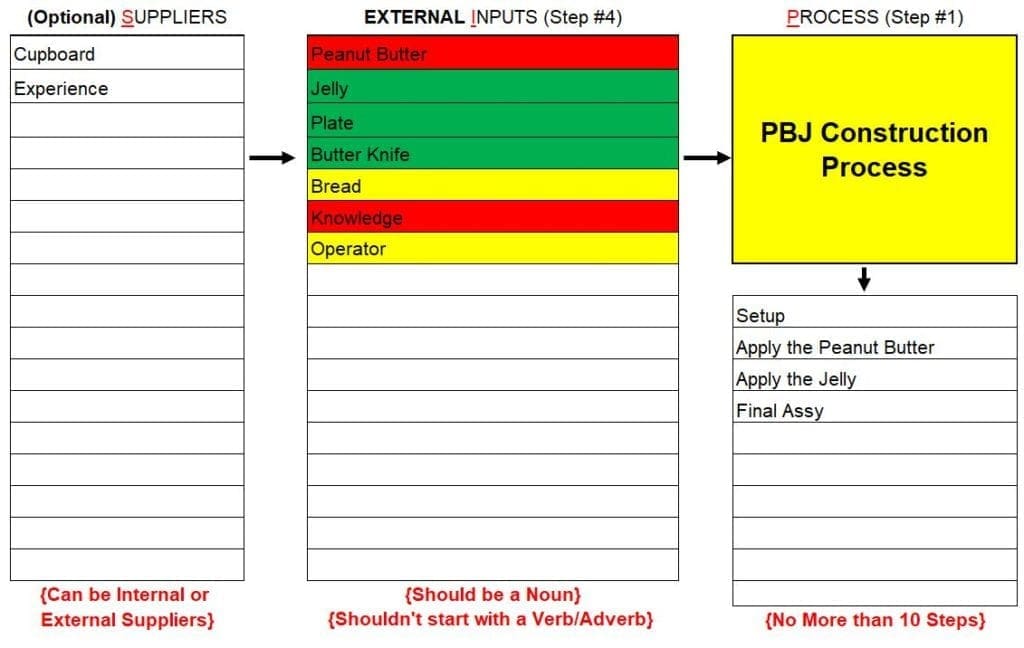

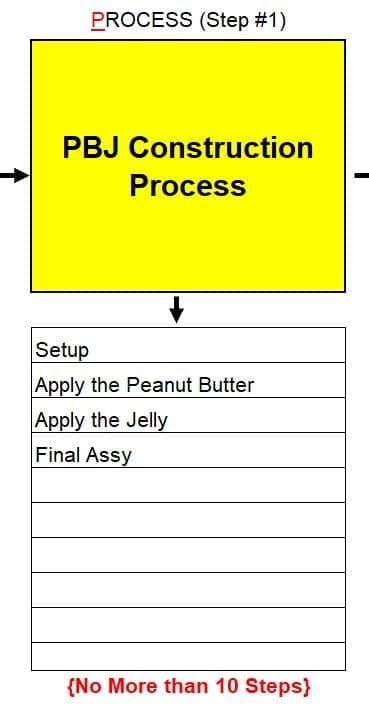

Below is an example of a completed SIPOC using a simulated project that we give to our Lean Six Sigma Green Belts and Black Belts as a benchmark to complete their Lean Six Sigma project. The project is focused on a company called PBJ, Inc. who makes thousands of Peanut Butter and Jelly sandwiches for kids in schools all over the continental United States. PBJ Inc is experiencing increased operating costs in the construction of PBJs and they do not know why. The SIPOC below is part of a project to determine the root cause. The first half of the SIPOC:

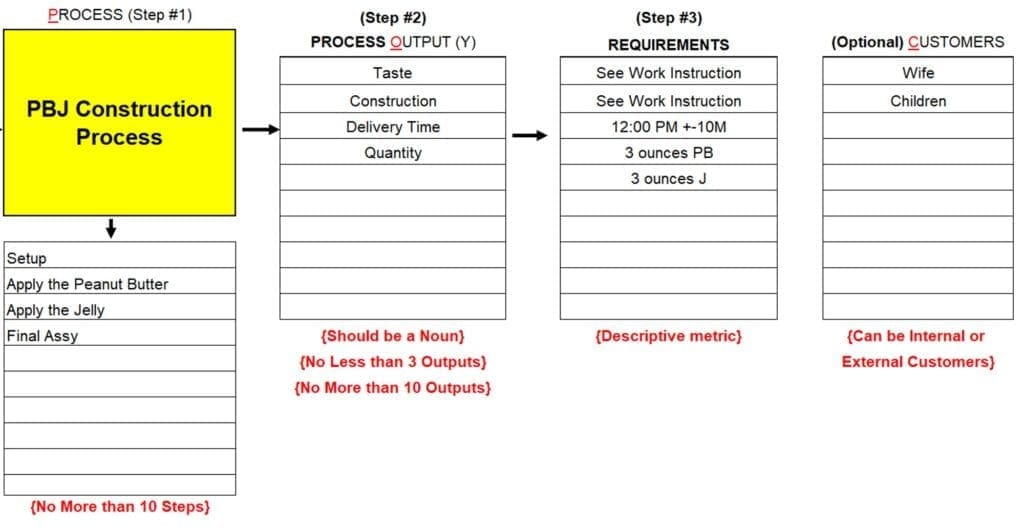

The second part of the SIPOC:

Step 1a: Fill out the “Process Name”

- State the process in which you believe the problem occurs

- In this example: “PBJ Process” is the Process Name (we believe that the increase in operating costs is occurring because of variation in the construction of peanut butter and jelly sandwiches.

Step 1b: Fill out the High-Level steps in the Process

- Use verbs or adjectives – how does the process operate from the 30-thousand-foot view

- These are not detailed steps (We will get to the detailed steps later in a tool called the Input Map)

- There should be no more than ten high level steps

- If you have more than ten steps, your project may be too large in scope

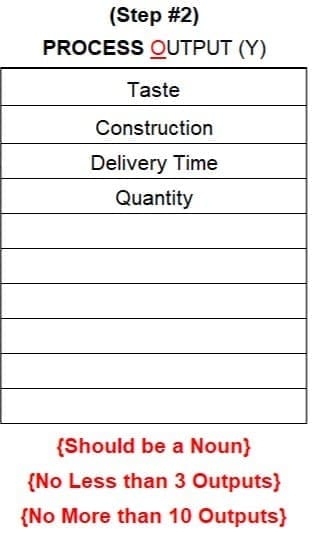

Step 2: Fill out the “Outputs” section

- Should have no less than three Outputs (this is important in a later Six Sigma Root Cause Analysis Tool).

- Use nouns – what does this process produce?

- Output should not contain verbs (action words) nor requirements (we will list requirements in another column)

- Outputs should not be written in the Positive (like “Good Taste”) or Negative (like “Bad Taste”) only in the Neutral (like “Taste”)

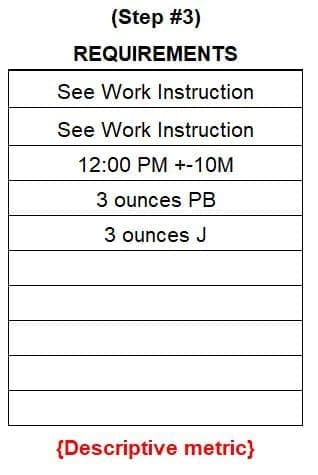

Step 3: What are the Requirements of the Outputs?

- The requirements are given in metrics or references to where the metrics exist

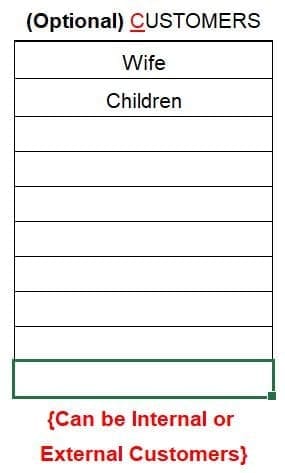

(Optional) Who are the “Customers”?

- Who receives the Output?

- Who will benefit from this process?

- Who will be upset if this process doesn’t work as required?

- Can be both Internal Customers and/or External Customers

Step 4: What are the External Inputs to the Process”?

- External Inputs are those Inputs that supplied to the process for the process to function

- These External Inputs are outside of the scope of our LEAN or Lean Six Sigma project

- These “External Inputs” are external to the “Process” that our Six Sigma Project is Focused.

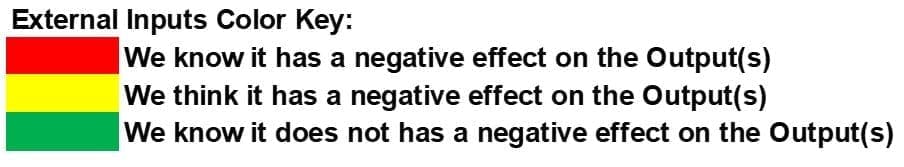

Once the External Inputs have been identified, we then color code them based on the effect they are presently having on the Outputs.

The External Input column is important in verifying that our focus is on the right place (the Process or the “P” in the SIPOC). We might find from the External Input column that we need to re-focus up stream to one or more External Inputs to truly solve the problem.

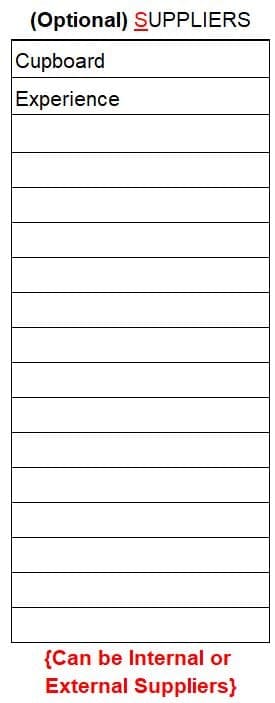

(Optional) Who Supplies the Inputs?

- Who supplies the External Inputs to the Process?

- You don’t need to list every specific supplier unless the specific supplier detail is important to the variation in the output.

- For Example, If the variation in taste is impacted by the different suppliers of Peanut Butter, then we would list the suppliers in that level of detail.

Once the SIPOC is completed, and the Scope (or Focus) of the Process that is to be Investigated has been verified, then you can move to the next step. The next step in the Six Sigma Root Cause Analysis is the Input (or Variables) Map.

Conclusion

The SIPOC is one of the most powerful tools in the Lean Six Sigma toolbox. It helps the process improvement team and the stakeholders understand the project scope and requirement. The SIPOC also helps the team understand if they are focused on the right process.

How could the SIPOC help you in your project?

Very clear explanation detailing “isolating the Process” as what is going to be studied and improved; however, warning that if the outside influences are making the process outputs variable then optimization and stabilization of these influences must be done FIRST. It should be mentioned that a good number of process flow chart analysis tools can be used as a follow-on and verification of the quick SIPOC identification of process controlled and uncontrolled inputs, target outputs and other more detailed factors — thus making the SIPOC process just a “big picture tool” which can be corrected once these follow-on tools are used.

Hello Kevin,

I would like to know about the meaning of Project Y1, Project Y2, Project Y3 on Output column that is in six-sigma-rca excel template I downloaded. You are saying those outputs from a macro process can be consider as a project?

Are there projects that will make my project successful. This is the meaning of this question? What numbers will make your project successful?

I am analysing PBJ Process to understand the example. If you can explain me with the same example of PBJ Process I think I can get it. If you can not, I have a study case:

I have an area called Network Planning and Study Management. This area has macro processes: Substation Development, Design and Engineering, Network Study, Distribution System Planning and Validation of Plans. Every macro process has procedures to do their corresponding activities or tasks.

My question is as follows and based on the PBJ Process exercise, can each macro process be considered in the P column of the SIPOC?

Attentive to your prompt response. Thanks in advance.