Table of contents

Top Black Belt Project Examples and Tips

Certified Lean Six Sigma Black Belt experts are professionals who know and can explain the Six Sigma philosophies and principles. This includes tools and supporting systems. A Black Belt must possess excellent leadership skills and be familiar with team dynamics. They assign roles and responsibilities to team members in a collaborative way. To obtain your Lean Six Six Sigma Black Belt level certification chart you must practice planning project management ideas, this is why we’ve gathered 10 examples for you to get inspired.

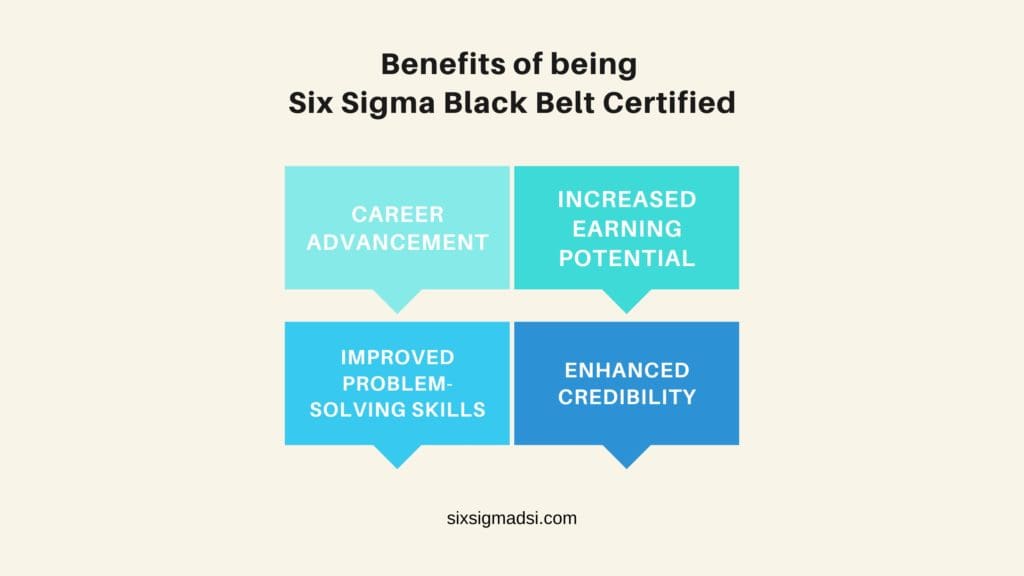

A Black Belt Certification will give you a competitive edge in your career. They are familiar with the DMAIC Model. The DMAIC chart model is based on the Six Sigma principle levels: define, measure and analyze, improve, and control.

This course will give you basic knowledge and concepts of lean. You will be able to identify elements and actions that are not value-added. You will be able to use specific tools for processing product quality and management. Three years of experience is required in at least one SSBB Body of Knowledge area.

Six Sigma Black Belt Project Requirements

- Two complete projects are required to obtain the Black Belt certification. The affidavits should include 3 years of experience in the field. Work experience must be related to Six Sigma Knowledge of Body.

- You must also show full-time experience in a salaried role. You can’t apply if you have any paid or unpaid internships, or freelance work.

- Professionals must have the ability to think innovatively and understand customer requirements and needs. The professional is expected to have leadership, collaboration skills, and effective communication.

- It is important to have a mindset that allows you to communicate and work efficiently. This will produce good financial results.

- It is also important to be passionate about quality improvement.

- Six Sigma Black Belt professionals need to be familiar with the statistical tools and technologies which can be used in project management planning.

What Are the Key Attributes Of A Good Project?

Six Sigma is composed of five phases or attributes. The five attributes listed below are in order.

1. Define

The define phase is the first phase of Lean Six Sigma Project planning. The problem and goals are stated in the defining phase. The problem must be stated and the goals defined accordingly. You are the Black Belt project leader and you will be responsible for creating the project charter, the developing process map, as well as other customer needs.

2. Measure or Count

This phase can also be called the beginning of a project. The team will work to choose the best measures for the project. They will develop a plan to collect data. In Phase-2, DMAIC, all data regarding the baseline and updated project charter are measured.

3. Analyze

Phase 3 of the DMAIC analyzes all the data collected and measured during Phase 2. You can examine each process in detail and identify the root causes (if any) of problems. You can use tools for data analysis and process analysis to visualize the information.

4. You can Improve Yourself

Phase 4 of DMAIC focuses on improving the solution after the analysis and measurement of the problem. To find the best solution, you can create a list of possible solutions and design future aspects. Be sure that your solutions will have positive results. You can know the risks and measure the improvements in the process.

5. Command and control

Control face is the last phase in DMAIC. Continually improve as you meet the goals. The control phase involves comprehensive planning and monitoring of the protocols developed and implemented. Lean Six Sigma is also a part of the improvement phase and one must practice planning throughout the project.

These five phases are referred to as DMAIC. This method is a systematic way to solve issues. Six Sigma’s goal is usually to solve a problem in business. Six Sigma has the potential to be used in virtually any industry, including sports, music, food, and health. Six Sigma’s power is attributed to its systematic and meticulous approach, as well as its comprehensive stages.

It’s crucial to know when this structured approach should be used in problem resolution before diving into the phases. The world is full of problems (which is what makes it so interesting). However, the complexity of these problems varies.

Six Sigma’s goal is for you to determine which factors or inputs have the greatest impact level on your output chart, and then optimize and control these inputs to receive the desired output.

You will have identified all the main elements by the time you reach the Control phase and you will know how to control them so you can deliver the desired output consistently. The Six Sigma practice is a method that provides a long-term, logical, documented, and data-driven approach to solving problems in a company.

Lean Six Sigma Black Belt Project Ideas With Examples

We have selected a few project ideas to display, including Lean and Six Sigma Case Studies. The projects have been completed in many different industries and sectors. Several projects have been completed in a short time, but others took months. Some projects have proven to be complex with multiple barriers while others have been straightforward.

We tried to choose lean six sigma project ideas that represent a variety of industries, levels of difficulty, planning, etc. The case studies we have selected below are meant to demonstrate the versatility and adaptability of Lean Six Sigma practice. They may also inspire you in your own Lean Six Sigma project.

1. Helical Wires on the Japanese Market

This Six Sigma Case Study examines the way our client’s manufacturing company was able to enter the Japanese market. Nine years of minor cosmetic issues prevented their products from being approved by Japanese consumers. Throughout the years, many attempts were made at solving the problem. Many hours, dollars, and efforts were wasted.

Solved: The problem was resolved in just three months when the DMAIC Lean Six Sigma Black Belt project management technique was finally in practice. The product that was created with the new settings and technique was accepted by two large Japanese clients. The manufacturer increased its revenue by $3 million after selling products to Japanese customers in just one year.

2. Drilling Fluids Company reduces inventory

This Six Sigma Case Study examines how our client, an oil and gas company, was able to drastically reduce inventory levels. The service level was not compromised. In six months, the inventory turnover of the company increased by 200 percent. It reached 3.5 turns. The number is still increasing.

Resolved: The result was a reduction of working capital and cash savings of tens of millions of dollars. This project needed a comprehensive Define phase, along with analyses. The oil and gas industry is complex, so the project’s goals were defined, measured accurately, and analyzed. The project is small but it requires a great deal of work.

3. Steel Productivity Improvement

This Six Sigma Case Study examines how we increased efficiency levels at a steel chart hardware manufacturer. The capacity was increased without any additional investment. Project heads detected problems with Lean Six Sigma practice planning. The analysis phase is where you can find out how to increase productivity and make the necessary cuts. The project leader was able to do wonders.

The desired results were achieved: Both capacity and productivity increased by more than 25%. The factory can now operate six days a week without having to reject any orders. The other Lean Six Sigma concepts must be used to maintain the output.

4. Capability reduces costs

Six Sigma Case Study: A company that produces formed steel wires can easily reduce product costs. It was the easiest cost-cutting project we’ve ever undertaken, yet it was very effective. The team used statistical tools and other techniques to come up with the best solution. It was simple to analyze and define, but implementing the control was a difficult task. The task was completed with the help of the basic tools.

Resolved: This is an excellent example of how simple tools can save you money. The average product cost was reduced by 1.3 percent. This product sold for around $30 million, which represents a direct savings of almost $400,000.

5. Call Centres can reduce the length of call times by implementing a time reduction policy

This Six Sigma Case Study examines how a call center was able to reduce the average handling time for inbound calls. The project was relatively small and took less time. The measures were increased by 18% after the correct follow-ups during the phase of defining and analyzing.

Resolved. The handling time average was reduced by 18%. This also increased capacity by 18%. The annual savings were in the millions for a call center with thousands of calls coming in per day.

6. Reduced Days of Sales Outstanding

This Lean Six Sigma project ideas examines a large oil and gas company that acquired several smaller firms over the years and planned to acquire more. To achieve this, they needed a large amount of money. With the Six Sigma basics, the task became easy.

Lean is the best strategy to increase cash flow. The DSO of most sites was reduced to under 100 days. The majority of sites saved over a half-million dollars. If you multiply it by 50 sites, that’s a lot of cash!

7. Online Prepaid Cellular Service Top-Up

This Six Sigma Case Study examines the challenges faced by a cellular provider with their online top-up level system, and how they were resolved using the DMAIC Process chart. This type of project requires a solid Define phase. It is easier to understand the analysis phase if you are aware of the problems and objectives you need to achieve within your cellular service.

The desired results were achieved: By taking the right measures, the success rate of registration has increased to 91%. Top-ups have a success rate of 90%. The revenue increased by more than $300,000.

8. Statistical Survey Analysis for Improvement

Six Sigma Case Study: This case study examines how a call center used survey results in order to decide what to do. Surveys are used by most businesses to assess their performance on different customer satisfaction criteria. The call center used statistical methods to analyze the results and determine the best ways to improve customer satisfaction.

The desired results achieved: We all know that customer satisfaction is an indicator of a statistic that takes time to take effect. In the first six-month period following the implementation of preliminary improvement initiatives, customer satisfaction rose by about 5%. The number will increase when the projects that spawned them are completed.

9. Reduce Lead Time in Aluminium Casting

This Lean Six Sigma project ideas and example examines how an aluminum casting manufacturing company was able to boost productivity and reduce production lead times through the practice of the Lean Six Sigma level principles chart. If the spawning project was completed, this would be increased. The factory completed a standard order within two weeks.

Solved: Productivity, and capacity were also increased. The sales team kept their promise by attracting more customers with a short lead time. The factory was able to accommodate the orders easily because it had increased its capacity recently with this project. The product price was also reduced because the factory now needed fewer overheads and labor hours.

10. Food Equipment manufacturers save thousands of dollars on annual warranty claims

A warranty is required for large equipment purchases to protect against defects. The customer must get the warranty to ensure that the sale will not be affected. These companies may lose clients if they fail to provide a warranty on their food processing equipment. If the warranty is not handled properly by the company it can result in a large loss.

Solution: Companies must keep costs under control while providing warranties to their customers. Here is where project leaders with a Lean Six Sigma Black Belt level can practice a role in a project planning management chart. The project leaders can create a culture that promotes continuous improvement and operational excellence by using their DMAIC models. They can help you deal with unnecessary payments and pay your bills on time.

Are you starting your Six Sigma Black Belt project?

Let us know if you have any questions, we can help!