Reproducibility in statistics refers to the ability to achieve the same results when an experiment, analysis, or measurement is repeated under the same conditions, but often by different people or teams. This means that if someone else uses the same data, methods, and procedures as the original study, they should be able to obtain consistent results.

Reproducibility is essential for building trust in scientific findings because it shows that results are not just due to chance or individual differences in technique, but are reliable and can be independently verified. In measurement systems, reproducibility specifically measures how much results vary when different operators use the same equipment and method to measure the same item; ideally, this variation should be minimal.

In summary, reproducibility ensures that scientific or statistical results are dependable, verifiable, and can be used as a foundation for further research or decision-making.

Table of contents

- What is Reproducibility in Statistics?

- Key Components of Reproducible Statistical Research

- How to Achieve Reproducibility in Statistics?

- Examples of Reproducible Statistical Research

- The Reproducibility Crisis and Its Impact

- Frequently Asked Questions on Reproducibility in Statistics

- Final Words

- Related Articles

What is Reproducibility in Statistics?

Reproducibility in statistics refers to the ability of independent researchers to obtain the same results using the same data, methods, and analytical processes as the original study. It’s a key pillar of the scientific method, ensuring findings are not flukes but reliable truths. Often confused with replicability, which involves new data collection to confirm results, reproducibility focuses on reusing existing data and code to verify outcomes.

For example, if a study claims a new drug reduces symptoms by 20%, another researcher should be able to use the same dataset, statistical models, and code to get the same result. Reproducible research builds trust, validates discoveries, and supports cumulative science.

As noted by the National Academy of Sciences, reproducibility is critical for advancing knowledge and maintaining public confidence in research.

Public, Onsite, Virtual, and Online Six Sigma Certification Training!

- We are accredited by the IASSC.

- Live Public Training at 52 Sites.

- Live Virtual Training.

- Onsite Training (at your organization).

- Interactive Online (self-paced) training,

Why is Reproducibility in Statistics Important?

Reproducibility is the backbone of credible research. Here’s why it matters:

- Builds Trust: Reproducible results assure stakeholders—scientists, policymakers, and the public—that findings are reliable.

- Drives Progress: It allows researchers to build on existing work, accelerating scientific discovery.

- Reduces Errors: Transparent methods catch mistakes early, improving research quality.

- Ensures Accountability: Sharing data and code holds researchers accountable, reducing fraud or bias.

- Supports Policy and Practice: Reproducible findings inform evidence-based decisions in fields like medicine and economics.

However, the reproducibility crisis—where many studies fail to replicate—has raised alarms. A 2016 Nature survey found that 70% of researchers couldn’t reproduce another scientist’s results, highlighting the urgency of addressing this issue.

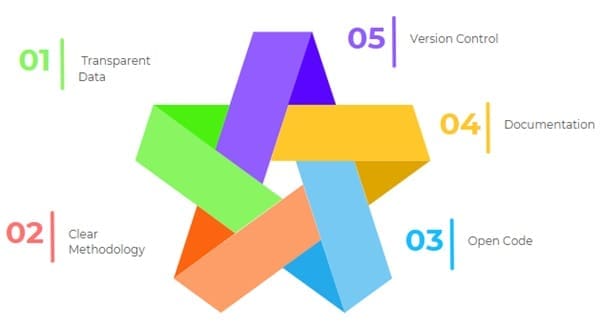

Key Components of Reproducible Statistical Research

To achieve reproducibility in statistics, several elements must align:

1. Transparent Data

- Share raw and processed datasets in accessible formats (e.g., CSV, JSON).

- Document data collection methods, including sources and preprocessing steps.

2. Clear Methodology

- Describe statistical models, assumptions, and parameters in detail.

- Use standardized reporting formats, like those recommended by the American Statistical Association.

3. Open Code

- Provide scripts (e.g., R, Python) that automate data analysis.

- Include comments to explain code logic and steps.

4. Documentation

- Create detailed README files or protocols outlining the analysis process.

- Use tools like Jupyter Notebooks for step-by-step documentation.

5. Version Control

- Track changes in data and code using platforms like Git or GitHub.

- Ensure all versions are archived for reference.

These components, as emphasized by sources like the National Institutes of Health, ensure others can replicate your work seamlessly.

Also Read: What Is Gage R&R: Gage Repeatability and Reproducibility?

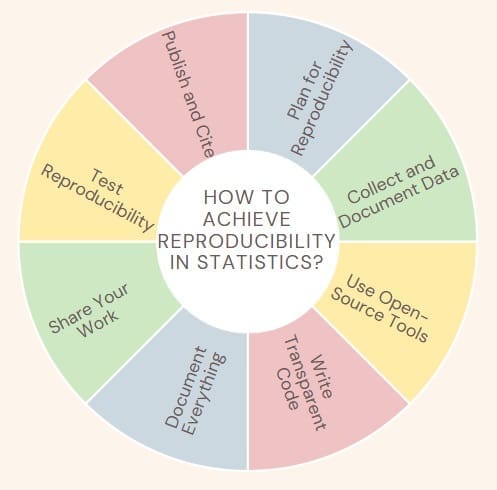

How to Achieve Reproducibility in Statistics?

Creating reproducible statistical research requires planning and discipline. Follow these steps to ensure your work stands the test of scrutiny:

Step 1: Plan for Reproducibility

Before starting, outline your data collection, analysis, and sharing strategy. Use a reproducible research checklist to guide your process

Step 2: Collect and Document Data

Gather data systematically, noting sources, sampling methods, and any cleaning steps. Store data in open formats and use repositories like Zenodo or Figshare for sharing.

Step 3: Use Open-Source Tools

Leverage software like R, Python, or Julia for analysis. These tools are widely accessible and support reproducibility through scripting. For example, R’s knitr package creates dynamic reports combining code and results.

Step 4: Write Transparent Code

Write clean, commented code that automates every analysis step. Use version control systems like Git to track changes and ensure traceability.

Step 5: Document Everything

Create comprehensive documentation, including:

- Data descriptions (e.g., variable definitions, units).

- Analysis steps (e.g., statistical tests, model specifications).

- Software versions and dependencies.

Tools like R Markdown or Jupyter Notebooks integrate code, results, and explanations for clarity.

Step 6: Share Your Work

Publish data, code, and documentation in public repositories like GitHub, Dryad, or OSF. Ensure they’re accessible under open licenses (e.g., CC-BY).

Step 7: Test Reproducibility

Ask a colleague or independent researcher to replicate your results using your shared materials. This validates your work before publication.

Step 8: Publish and Cite

Submit your findings to journals that prioritize reproducibility, like those following TOP

Examples of Reproducible Statistical Research

To illustrate, here are two reproducibility in statistics examples:

1. Medical Research

A study on a new diabetes treatment shares its dataset (patient glucose levels), R code for statistical analysis (t-tests, regression), and a Jupyter Notebook explaining each step. Another researcher downloads these materials from OSF, runs the code, and confirms the reported 15% improvement in glucose control.

2. Social Science

A survey on voter behavior uses Python to analyze responses. The researcher shares the dataset, code, and a detailed README on GitHub. A peer replicates the analysis, verifying the reported correlation between age and voting preference.

These examples show how reproducible research builds trust and enables validation.

Tools for Reproducible Statistical Research

Several tools make reproducibility in statistics easier:

- R and RStudio: Open-source software for statistical analysis with packages like knitr and rmarkdown for dynamic reporting.

- Python and Jupyter Notebooks: Ideal for combining code, visualizations, and explanations in one document.

- Git and GitHub: Track changes and share code and data publicly.

- Zenodo and Figshare: Repositories for archiving datasets and documentation.

- Docker: Creates containers to replicate software environments, ensuring consistency.

- Open Science Framework (OSF): A platform for managing and sharing research materials.

Challenges of Achieving Reproducibility

Despite its importance, reproducibility in statistics faces hurdles:

- Data Access: Proprietary or sensitive data (e.g., medical records) may not be shareable.

- Complex Analyses: Intricate models or custom software can be hard to replicate.

- Time and Effort: Documenting and sharing materials requires extra work.

- Lack of Standards: Inconsistent reporting practices across fields complicate reproducibility.

- Cultural Resistance: Some researchers hesitate to share data due to competition or privacy concerns.

Overcome these by using open tools, adopting standard guidelines, and fostering a culture of transparency.

Best Practices for Reproducible Statistical Research

To maximize reproducibility in statistics, follow these best practices:

- Start Early: Plan for reproducibility from the project’s outset to avoid rework.

- Use Open Formats: Store data in CSV or JSON to ensure accessibility.

- Automate Analyses: Write scripts to eliminate manual steps and reduce errors.

- Document Thoroughly: Include clear instructions for replicating each step.

- Validate Results: Test your code and data on different systems to ensure consistency.

- Engage the Community: Share preprints and invite feedback to improve transparency.

Also Read: What is Microfluidics Manufacturing?

The Reproducibility Crisis and Its Impact

The reproducibility crisis has shaken trust in science. Studies in psychology, medicine, and economics have faced challenges when others couldn’t replicate their findings. For instance, a 2015 study in Science found that only 39% of 100 psychology studies were reproducible. This crisis stems from:

- Poor documentation of methods and data.

- Overreliance on p-values without robust statistical practices.

- Publication bias favoring novel results over replication studies.

Addressing this requires a cultural shift toward transparency, as advocated by organizations like the Center for Open Science.

Reproducibility in Different Fields

Reproducibility in statistics varies by discipline:

- Medical Research: Requires strict documentation due to regulatory oversight (e.g., FDA guidelines).

- Social Sciences: Faces challenges with subjective measures but benefits from shared datasets.

- Environmental Science: Relies on open data to model complex systems like climate change.

- Economics: Uses large datasets and econometric models, making code sharing critical.

Each field can leverage reproducible research to enhance credibility and impact.

Frequently Asked Questions on Reproducibility in Statistics

What is reproducibility in statistics?

Reproducibility in statistics is the ability to obtain the same results using the same data, methods, and code as the original study, ensuring research reliability.

Why is reproducibility important in statistical research?

It builds trust, supports scientific progress, reduces errors, ensures accountability, and informs reliable policy and practice decisions.

How can I achieve reproducibility in my research?

Plan early, use open-source tools like R or Python, document thoroughly, share data and code, and validate results. Use our template [internal link suggestion: /reproducible-research-template].

What tools support reproducible statistical research?

Answer: Tools like R, Python, GitHub, Zenodo, and Jupyter Notebooks enable transparent data analysis and sharing.

What is the reproducibility crisis?

The reproducibility crisis refers to the difficulty in replicating many scientific studies, often due to poor documentation, biased reporting, or inaccessible data.

Final Words

Reproducibility in statistics is the foundation of trustworthy research. By ensuring others can verify your results, you build credibility, drive progress, and contribute to reliable science. From transparent data to open code, every step matters in overcoming the reproducibility crisis. Whether you’re in medicine, economics, or environmental science, adopting reproducible practices can transform your work.