A pilot run, also known as a trial production run or production validation test (PVT), is a small-scale manufacturing process conducted before full-scale production. It involves producing a limited quantity of a product under actual production conditions to evaluate the feasibility, functionality, and efficiency of the manufacturing process.

Table of contents

What is a Pilot Run?

A pilot run, also known as a pilot test or pilot project, represents a small-scale, preliminary implementation of a new product, service, process, or business model. We conduct it before a full-scale launch or widespread adoption. Think of it as a trial run in a controlled environment.

This allows us to test the waters, identify potential problems, and gather valuable feedback before committing significant resources to a full rollout.

Imagine a bakery planning to launch a new type of bread. Instead of immediately producing thousands of loaves and distributing them across all their stores, they might first conduct a pilot run. This involves baking a smaller batch of the new bread and offering it in just one or two select stores.

This allows them to assess customer reception, identify any issues with the baking process, and refine the recipe or marketing before a larger launch.

Public, Onsite, Virtual, and Online Six Sigma Certification Training!

- We are accredited by the IASSC.

- Live Public Training at 52 Sites.

- Live Virtual Training.

- Onsite Training (at your organization).

- Interactive Online (self-paced) training,

Purpose

The primary purpose of a pilot run is to mitigate risks and ensure a smoother, more successful full-scale implementation. It serves several key objectives:

- Identify and Resolve Issues: A pilot run helps us uncover potential problems, bugs, or inefficiencies in the new product, service, or process early on. This includes issues related to functionality, usability, production, logistics, or customer experience.

- Validate Assumptions: We often make assumptions when developing new offerings or processes. A pilot run provides an opportunity to test these assumptions in a real-world setting.

- Gather Feedback: Pilot runs allow us to collect valuable feedback from a small group of users or stakeholders. This feedback can provide insights into customer preferences, usability challenges, areas for improvement, and overall satisfaction.

- Assess Feasibility: A pilot run helps us determine the feasibility of the full-scale implementation. This includes evaluating the required resources, timelines, costs, and logistical considerations. It allows us to identify any potential roadblocks or challenges that might arise during a larger rollout.

- Optimize Processes: When testing a new process, a pilot run allows us to evaluate its efficiency, identify bottlenecks, and optimize workflows before full implementation. This ensures a smoother and more effective operation in the long run.

- Gain Stakeholder Buy-in: A successful pilot run can provide tangible evidence of the new offering’s potential benefits, making it easier to secure support and buy-in from key stakeholders, including management, investors, and employees.

- Train Personnel: Pilot runs can serve as a training ground for the teams involved in the new product, service, or process. This allows them to become familiar with new procedures, technologies, or systems on a smaller scale before a full rollout.

Key Objectives

- Process Validation: Ensuring that the manufacturing processes are capable of producing products that meet quality standards.

- Identifying Issues: Detecting potential problems in design, materials, equipment, or workflows before mass production.

- Training Opportunities: Providing a platform for training operators and staff on new processes or equipment.

- Supply Chain Assessment: Evaluating the readiness of suppliers and logistics to support full-scale production.

- Quality Assurance: Verifying that the final product meets customer specifications and regulatory requirements.

Also Read: What is Design for Six Sigma?

Importance

Pilot runs offer several advantages that contribute to the overall success of a manufacturing project:

1. Risk Mitigation

By identifying and addressing potential issues early, pilot runs help in mitigating risks associated with defects, delays, and cost overruns during full-scale production.

Pilot runs provide valuable insights into the efficiency of manufacturing processes, enabling manufacturers to optimize workflows, reduce waste, and enhance productivity.

Conducting pilot runs allows for thorough testing of the product’s quality, ensuring that it meets the desired standards and specifications before reaching the market.

4. Cost Savings

By uncovering issues early, pilot runs help in avoiding costly recalls, reworks, or production stoppages, ultimately saving time and money.

5. Stakeholder Confidence

Successful pilot runs build confidence among stakeholders, including investors, customers, and regulatory bodies, by demonstrating the manufacturer’s commitment to quality and reliability.

Pilot Run vs. Beta Testing

While both pilot runs and beta testing involve real users testing a new offering before a full launch, there are some key differences:

| Feature | Pilot Run | Beta Testing |

| Scope | Focused on a specific process, production line, or system | Encompasses a broader set of features or complete product experience |

| Environment | May occur in a controlled test environment or on-site real-world setup | Conducted in real-world user environments |

| Timing | Happens at different points (mid-development, pre-production, process changes) | Happens later in the development cycle, close to product release |

| Purpose | Validate feasibility, fine-tune operations, and identify technical/process flaws | Identify functional bugs, test usability, and gauge user satisfaction |

| User Group | Internal team members, technical experts, limited end users | General users, broader demographics, potential customers |

| Feedback Type | Both qualitative and quantitative: includes production data, performance logs | Mostly qualitative: user feedback, bug reports, usability issues |

| Primary Focus | Process validation, readiness for mass production | Product functionality, interface experience, user satisfaction |

| Output Volume | Limited production volume, sometimes sellable but often for testing only | Full or limited feature set offered to testers; not always production quality |

| Training Involvement | Used for internal training on new processes or equipment | Not used for training; focuses on how intuitive and user-friendly the product is |

| Risk Level | Technical and operational risk is tested and minimized | User experience and market perception risks are tested |

| Iterative Nature | May require multiple pilot runs to perfect the process | Usually one or two rounds before release |

| Duration | Can last days to weeks depending on complexity | Typically lasts for a few weeks |

| Measurement Criteria | Yield rate, downtime, defect detection, throughput | User engagement, error reports, task completion rates |

| Involvement of QA | High involvement – quality assurance monitors process reliability | QA may oversee bug reporting, but users provide most feedback |

| Regulatory Use | Common in regulated industries (e.g., pharma, aerospace, medical devices) | Less used for compliance; more for usability and feature validation |

| Example Use Case | Testing a new assembly line for an EV battery production | Testing a new app version with real users to detect usability issues |

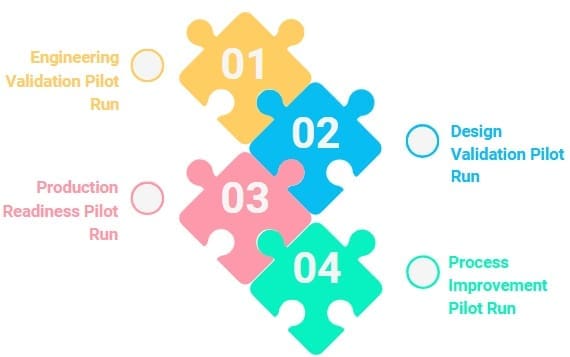

Types of Pilot Runs

Pilot runs can vary in scope and purpose, depending on the stage of product development and the specific objectives of the manufacturer:

1. Engineering Validation Pilot Run

This type of pilot run focuses on validating the engineering aspects of the product, such as design, functionality, and manufacturability. It is typically conducted during the early stages of product development.

2. Design Validation Pilot Run

Aimed at confirming that the product design meets user needs and expectations, this pilot run involves producing a limited quantity of the product to gather feedback and make necessary adjustments.

3. Production Readiness Pilot Run

Conducted before full-scale production, this pilot run assesses the readiness of manufacturing processes, equipment, and personnel to handle large-scale production efficiently.

4. Process Improvement Pilot Run

Implemented when introducing changes to existing processes, this pilot run helps in evaluating the impact of process modifications and ensuring that improvements are effective.

Steps Involved in a Pilot Run

Here’s a general outline of the key stages involved:

- Define Objectives and Scope: Clearly articulate what we want to achieve with the pilot run and define its boundaries. What specific aspects of the new offering or process will we test? What are the key questions we want to answer?

- Develop a Detailed Plan: Create a comprehensive plan that outlines all the activities, timelines, resources, and responsibilities involved in the pilot run. This plan should include the selection of participants, the duration of the pilot, the data collection methods, and the evaluation process.

- Select Participants: Choose a representative group of users or stakeholders who will participate in the pilot run. This group should ideally reflect the characteristics of the broader target audience or the employees who will eventually use the new process.

- Allocate Resources: Identify and allocate the necessary resources for the pilot run, including personnel, budget, equipment, and materials.

- Execute the Pilot: Implement the pilot run according to the defined plan. This involves deploying the new product, service, or process to the selected participants and allowing them to interact with it in a real-world or simulated environment.

- Monitor Progress and Collect Data: Throughout the pilot run, closely monitor its progress and collect relevant data based on the defined metrics. This may involve surveys, interviews, usage data, performance metrics, and feedback forms.

- Analyze Data and Feedback: Once the pilot run is complete, analyze the collected data and feedback to identify any issues, gather insights, and evaluate the pilot’s success against the defined objectives and criteria.

- Document Findings and Lessons Learned: Document all the findings, issues identified, feedback received, and lessons learned during the pilot run.

- Iterate and Refine: Based on the analysis of the pilot run, make necessary adjustments and refinements to the product, service, process, or implementation plan.

- Make a Decision: Based on the results of the pilot run and the subsequent iterations, make an informed decision about whether to proceed with the full-scale implementation, make further modifications, or abandon the initiative.

Also Read: What is Simulation?

How to Plan a Successful Pilot Run?

Planning is paramount for a successful pilot run. Here are some key steps to consider:

- Clearly Define Objectives: What specific goals do we want to achieve with this pilot? What questions do we need to answer? Ensure the objectives are SMART (Specific, Measurable, Achievable, Relevant, Time-bound).

- Determine the Scope: What specific aspects of the new offering or process will be included in the pilot? Keep the scope manageable to ensure focused testing and easier evaluation.

- Identify Key Stakeholders: Who needs to be involved or informed about the pilot run? Secure their buy-in and support early on.

- Select the Right Participants: Choose a representative group that aligns with the target audience or end-users. Consider their demographics, usage patterns, and willingness to provide feedback.

- Develop a Detailed Plan: Outline the activities, timelines, resources, and responsibilities. Include a communication plan to keep everyone informed.

- Define Success Metrics: How will we measure the success of the pilot run? Identify key performance indicators (KPIs) that align with the objectives.

- Establish Data Collection Methods: Determine how we will collect feedback and data (e.g., surveys, interviews, usage analytics).

- Allocate Sufficient Resources: Ensure that adequate budget, personnel, equipment, and time are allocated for the pilot run.

- Develop a Communication Strategy: How will we communicate with the participants and stakeholders throughout the pilot? Establish clear channels and frequency of communication.

- Plan for Evaluation and Iteration: Define how the collected data will be analyzed and how the findings will be used to make improvements. Be prepared to iterate based on the feedback.

- Have a Contingency Plan: Identify potential risks and develop backup plans to address any unforeseen issues that may arise during the pilot.

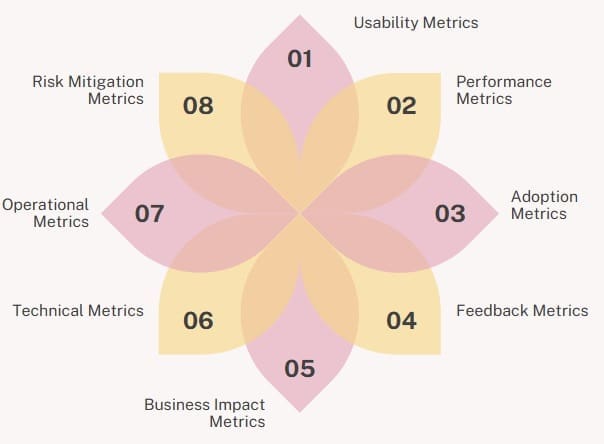

Key Metrics for a Pilot Run

To effectively evaluate the success of a pilot run, we need to track relevant metrics. These metrics will vary depending on the objectives and the nature of the pilot, but some common examples include:

- Usability Metrics: Task completion rates, time on task, error rates, user satisfaction scores (e.g., through surveys).

- Performance Metrics: System response time, efficiency gains, error rates in a process.

- Adoption Metrics: Usage frequency, feature adoption rates, number of active users.

- Feedback Metrics: Qualitative feedback from surveys and interviews, number of reported issues or bugs.

- Business Impact Metrics: Sales figures (for a new product), cost savings (for a new process), customer satisfaction scores.

- Technical Metrics: System stability, integration issues, performance under load.

- Operational Metrics: Resource utilization, process efficiency, cycle times.

- Risk Mitigation Metrics: Number of critical issues identified and resolved during the pilot.

Best Practices for Successful Pilot Runs

To maximize the effectiveness of pilot runs, manufacturers should adhere to the following best practices:

1. Cross-Functional Collaboration

Involve all relevant departments, including engineering, quality assurance, production, and supply chain, to ensure comprehensive testing and validation.

2. Clear Communication

Maintain open and clear communication among all stakeholders to facilitate the smooth execution of the pilot run and timely resolution of issues.

3. Detailed Documentation

Keep thorough records of the pilot run process, including objectives, procedures, data collected, and outcomes, to support decision-making and future improvements.

4. Continuous Monitoring

Monitor the pilot run continuously to detect and address issues promptly, minimizing disruptions and ensuring accurate data collection.

5. Post-Pilot Review

Conduct a post-pilot review to assess the effectiveness of the pilot run, identify lessons learned, and apply insights to future projects.

Also Read: Six Sigma Training for Beginners

Benefits

Conducting a pilot run offers numerous benefits, contributing to a higher likelihood of success for the full-scale implementation:

- Reduced Risk: By identifying and addressing potential problems early on, we significantly reduce the risk of costly failures and negative consequences during the full launch.

- Cost Savings: Fixing issues during a small-scale pilot run is far less expensive than dealing with widespread problems after a full rollout. We can optimize resource allocation and avoid costly mistakes.

- Improved Quality: The feedback and insights gained from the pilot run allow us to refine and improve the quality of the product, service, or process before it reaches a wider audience.

- Increased User Satisfaction: By incorporating user feedback and addressing usability issues during the pilot phase, we can ensure a better user experience and higher customer satisfaction with the final product or service.

- Faster Time to Market (in the long run): While a pilot run adds time to the initial stages, it can ultimately lead to a faster and smoother full-scale launch by preventing delays and rework caused by unforeseen problems.

- Enhanced Stakeholder Confidence: A well-executed and successful pilot run builds confidence among stakeholders, demonstrating the viability and potential of the new initiative.

- Better Resource Allocation: The insights gained from the pilot help us to better understand the resource requirements for the full-scale implementation, leading to more efficient allocation of budget, personnel, and materials.

- Data-Driven Decisions: Pilot runs provide valuable data and evidence to support decision-making regarding the full-scale implementation, reducing reliance on assumptions and guesswork.

Challenges in Conducting Pilot Runs

While pilot runs offer numerous benefits, manufacturers may encounter several challenges:

1. Resource Constraints

Pilot runs require significant resources, including time, materials, and personnel, which may strain existing capabilities.

2. Limited Scope

The small scale of pilot runs may not fully replicate the complexities of full-scale production, potentially overlooking certain issues.

3. Resistance to Change

Employees and stakeholders may resist changes introduced during pilot runs, hindering the implementation of improvements.

4. Data Interpretation

Interpreting data from pilot runs can be complex, requiring expertise to distinguish between anomalies and genuine issues.

Case Studies of Pilot Runs in Various Industries

1. Automotive Industry

In the automotive sector, pilot runs are essential for testing new vehicle models and manufacturing processes. For instance, before launching a new car model, manufacturers conduct pilot runs to evaluate assembly lines, part compatibility, and quality control measures. These pilot runs help in identifying potential issues and making necessary adjustments before mass production.

2. Electronics Manufacturing

Electronics manufacturers utilize pilot runs to test new products and production techniques. Specifically, before producing a new smartphone model, companies conduct pilot runs to assess assembly processes, component sourcing, and product functionality. These trials ensure that the final product meets quality standards and performs as expected.

3. Pharmaceutical Industry

In the pharmaceutical industry, pilot runs are crucial for validating manufacturing processes and ensuring compliance with regulatory standards. Before scaling up production of a new drug, companies perform pilot runs to test equipment, procedures, and product quality. These runs help in identifying potential risks and ensuring patient safety.

Final Words

The pilot run successfully demonstrated the feasibility and effectiveness of the proposed system/process under controlled conditions. Key insights were gathered regarding performance, user experience, and areas for improvement.

Consequently, while minor adjustments are needed before full-scale implementation, the results validate the overall approach and provide a solid foundation for scaling. Moving forward, incorporating feedback and refining operations will be essential to ensure seamless deployment and sustained success.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.