Table of contents

Estimated reading time: 8 minutes

What is the Voice of the Process (VOP)?

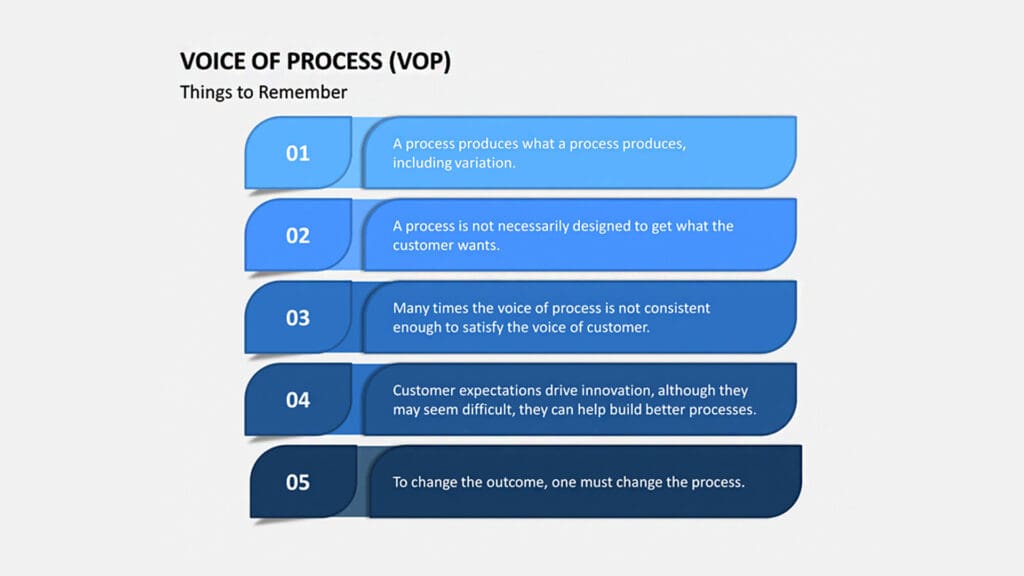

The term “Voice of the Process” (VOP) is often used in the context of process improvement and quality management. Voice of Process is a concept associated with Six Sigma, a set of techniques and tools for process improvement. The Voice of the Process is one of three key “Voices” in Six Sigma, the others being the Voice of the Customer (VOC) and the Voice of the Business (VOB).

- Voice of the Customer (VOC): This represents the needs and expectations of the customer. Understanding and incorporating the voice of the customer is crucial for delivering products or services that meet or exceed customer expectations.

- Voice of the Process (VOP): This represents the internal workings of the process itself. Analyzing the VOP involves studying the process parameters, variables, and performance metrics to ensure that the process is operating efficiently and effectively.

- Voice of the Business (VOB): This represents the goals and objectives of the business. It includes the financial and strategic aspects that are important to the overall success of the organization.

In the context of Six Sigma, the goal is to align the voice of the process with the voice of the customer and the voice of the business. This involves improving the process so that it not only meets customer requirements but also contributes to the overall success of the business. Analyzing the VOP often involves statistical methods to understand the variation and performance of the process, with the ultimate aim of reducing defects and improving efficiency.

By understanding and addressing the Voice of the Process, organizations can make data-driven decisions to enhance the quality and performance of their processes, leading to improved customer satisfaction and business success.

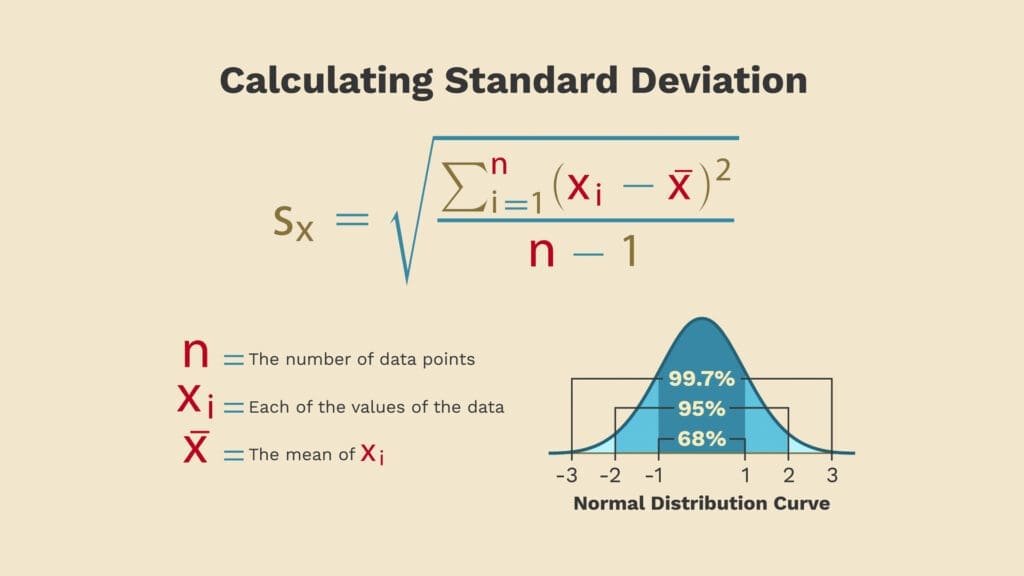

Standard Deviation and Mean

The standard deviation and mean are the most used statistical measures for a process. After these measures are calculated, it is possible to conduct a capability study. A capability study is a measurement of the standard deviation between the process average (in sigma units) and the closest spec limit. A process’s standard deviation will increase as the average moves from the middle of tolerance. In other words, there will be fewer standard deviations between the average and the nearest specification limit. The probability of items not being specified increases when they are close to the limits.

Each stable process has a predictable range for performance. Stable processes are those that are under statistical control. This means that special causes have been eliminated. Performance is only affected by normal operations. Performance measures are determined by the mean of outcome values that reflect the customer’s expectations.

For the most critical processes, organizations must have a reliable way to gather timely and consistent data. These processes must satisfy both the internal and external customers’ requirements in order to survive.

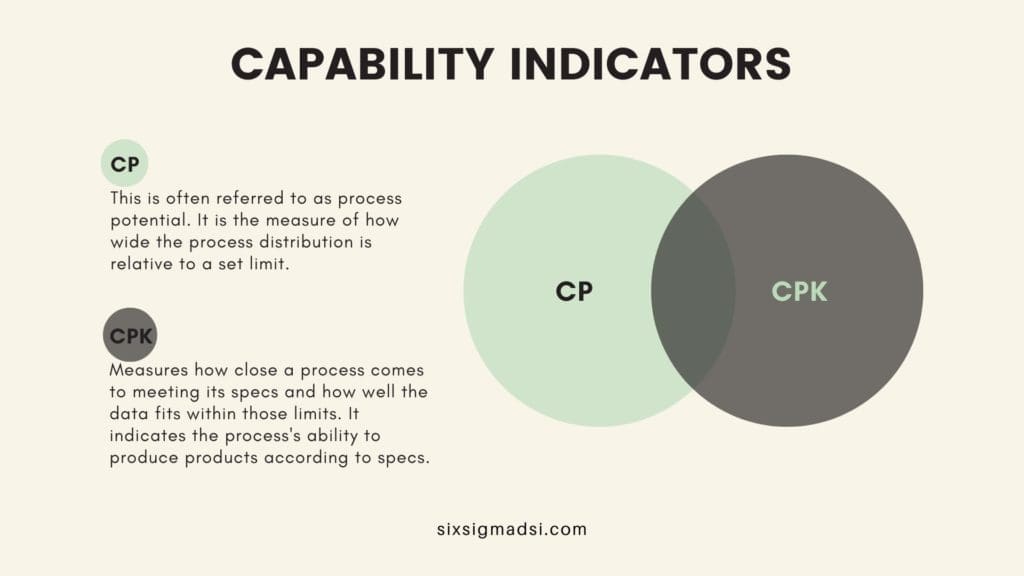

VOP Capability Indicators

Two of the most common indices used to determine whether a process can satisfy its customers are:

- CP, which is used to measure variation or whether data falls within specified limits (USL, LSL). This is often referred to as process potential. It is the measure of how wide the process distribution is relative to a set limit.

- CPK measures how close a process comes to meeting its specs and how well the data fits within those limits. It indicates the process’s ability to produce products according to specs.

Are the Specs Accurate?

These process capability indices can only be used if the specs are accurate. Process capability is a function of the specs. Processes that are under statistical control, and otherwise distributed, can be considered capable. The process capability indices are used to measure the “natural variability” that a process experiences relative to its specification limits. This allows for different processes to be compared in terms of how well an organization controls them.

The greater the CPK, the more stable a process is and the less likely that any item will be outside of the specification. Cp for a process lies in the range of 1.33 to 2.0. A process is considered not capable if it has a Cpk below 1.0. However, if the value is greater than 1.0 it is considered to be capable. Cpk values should be between 1.33 (minimally acceptable industry level to satisfy customers), and 2.0 for six-sigma processes.

Determine What the Customer Will Take

Here’s an example: A study was done on the wait time at a hospital for service over a period of four weeks. Data collected to conduct a process capability study shows how the process is centered as well as its variability. According to the clinic study, the average wait time for the service was 8 minutes. The standard deviation was 1 minute.

What is the process’ ability to meet customer expectations? This is a difficult question for most companies to answer. We don’t know the customer’s tolerance for waiting longer than necessary to receive a service. While organizations can spend a lot trying to reduce wait times to zero, it may not be what the customer is expecting.

How Well Does the Organization Meet Customer Expectations?

The true question for an organization is: How well does it meet customer expectations? Because they don’t know their customers’ expectations, this is a difficult question for service providers to answer.

Many processes in the public and private sectors, including healthcare, do not require customers to specify their requirements. Acceptable limits must be established for processes that do not have customer specs. Tolerable variations must be identified by actual customers of the process. The authors suggest developing an Upper Toleration Limit and Lower Toleration Limit to allow for either Run Charts or Control Charts. These Lower Toleration Limits (UTL and LTL) will replace the Upper and Lower Control Limits in order to calculate CP and CPK.

A customer may be asked a question like: “How long do you want to wait to see a doctor for a flu shot?”

Many customers know that waiting times are inevitable. Therefore, it is important to get an average of wait time from several customers. While everyone would prefer to have no wait time, most people are willing to accept a minimum wait. It is important to define the minimum acceptable wait as the Lower Specification Limit. It is possible to spend a lot of time trying to reduce wait times to zero. This may not be what the customer expects. Our limited resources should be used to improve our processes and meet customer expectations.

Benefits of Voice of the Process

Analyzing the Voice of the Process can yield several benefits:

Process Understanding:

- VOP provides insights into how the process is performed in real time. Understanding the current state of the process is crucial for making informed decisions about improvement.

Identifying Variability:

- By listening to the Voice of the Process, organizations can identify variations and deviations from the expected or desired performance. This information is essential for identifying areas that need attention or improvement.

- VOP is a key element in the continuous improvement cycle. It allows organizations to continuously monitor and evaluate their processes, making incremental changes to achieve better performance over time.

Data-Driven Decision Making:

- Using the Voice of the Process ensures that decision-making is based on real data and not just assumptions or perceptions. This helps in making more accurate and effective decisions.

Root Cause Analysis:

- When issues or variations are identified through the Voice of the Process, it becomes easier to conduct root cause analysis. Understanding the underlying causes of problems is essential for implementing effective corrective and preventive actions.

Quality Management:

- VOP is closely related to the concept of quality management. By monitoring the Voice of the Process, organizations can ensure that products or services meet or exceed quality standards consistently.

Customer Satisfaction:

- The Voice of the Process can be linked to customer satisfaction. By improving processes based on real-time data, organizations can enhance the quality of products or services, leading to higher customer satisfaction.

Cost Reduction:

- Identifying and addressing inefficiencies in the process through the Voice of the Process can lead to cost savings. Streamlining operations and reducing waste contribute to overall cost reduction.

Performance Metrics:

- VOP provides valuable metrics for assessing and measuring the performance of processes. This includes key performance indicators (KPIs) that can be used to track progress and success in meeting organizational goals.

Risk Management:

- Monitoring the Voice of the Process helps in identifying potential risks and vulnerabilities in the system. This proactive approach enables organizations to implement risk mitigation strategies before issues escalate.

The Voice of the Process is a powerful tool for organizations seeking to optimize their operations, enhance product or service quality, and achieve sustainable improvement over time. It enables a data-driven approach to decision-making and empowers organizations to respond quickly to changes and challenges in their environment.