Table of contents

- How to Select a Winning Lean Six Sigma Green Belt Project?

- How do you know when the wrong project is selected?

- Characteristics of a “Good” Lean Six Sigma Project

- How to Select the Right Lean Six Sigma Green Belt Project?

- Questions to Ask When Identifying a Six Sigma Project

- More warning signs of a “bad” Lean Six Sigma Green Belt project

- Conclusion

- Related Articles

Estimated reading time: 8 minutes

How to Select a Winning Lean Six Sigma Green Belt Project?

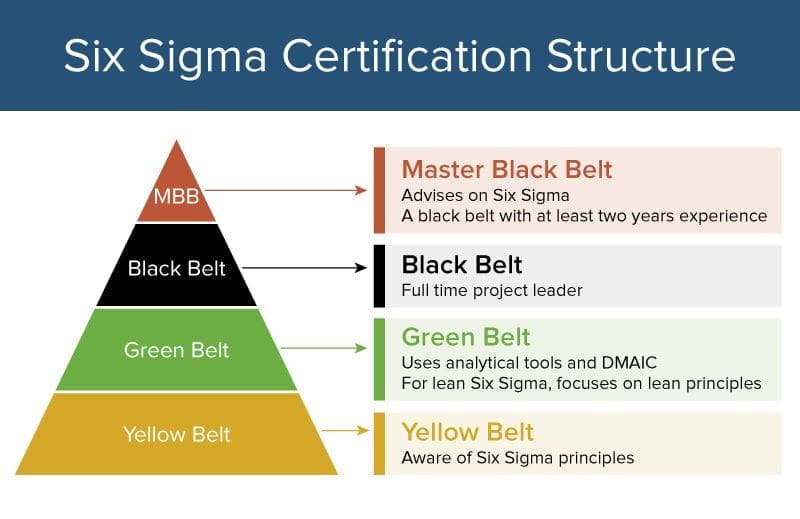

Six Sigma is a systematic and data-driven methodology for process improvement. In Six Sigma, the concept of “belts” refers to the levels of expertise and responsibility individuals have within the methodology. These belts are similar to the ranking system in martial arts and signify the level of training and proficiency in implementing Six Sigma principles and tools. Lean Six Six Sigma Green Belt project selection is a critical part of the continuous improvement effort. Like other Lean Six Sigma tools, project selection should be quantifiable, based on objective data, and not subjective guesswork.

A Lean Six Sigma Green Belt project is a problem that is planned for resolution. Lean Six Sigma projects are connected to the company’s strategic goals (or KPIs). They solve customers’ (whether internal or external) problems. A successful project should lead to cost savings, improvements in quality, and added capacity. It can also be used to satisfy the needs of shareholders. Only a limited number of Lean Six Sigma practitioners can be employed by an organization. This means that only projects with the highest potential for success and the greatest benefit to the company should be implemented.

How do you know when the wrong project is selected?

Before I tell you what the attributes are of a “Good” Lean Six Sigma project, I think it would be valuable to recognize a “Bad” project (one that will end in failure). A “Bad” project usually fits into one or more of six categories:

- The Goal Statement on the Project Charter is something like “Solve world hunger” (this means that the project scope is too large and will lead to failure)

- The project team does not know what the customer really wants and therefore has no goal metric

- The project team has no historical data on the process and can’t prove baseline performance

- The project team has little, or no data being collected on the inputs (or variables) that could affect the process (this means that the only analysis that can be performed is purely anecdotal)

- The project team has little to no control over the inputs that could affect the process

- The project team has no defined and formally trained “Champion” to remove roadblocks

Characteristics of a “Good” Lean Six Sigma Project

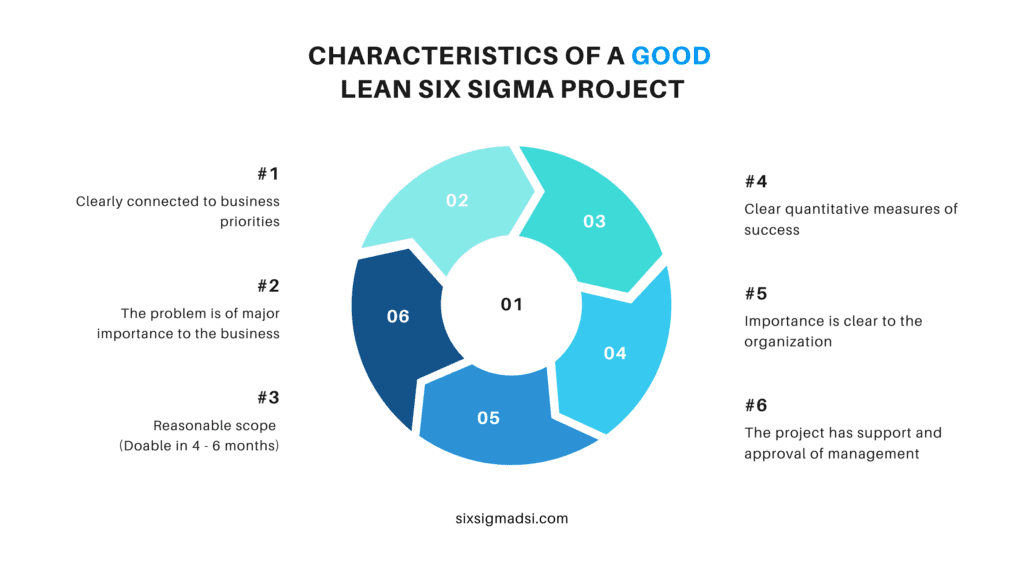

Lean Six Sigma Green Belt projects that will have a measurable effect on the organization and a rapid return on investment have six clear attributes:

- Clearly connected to business priorities

- Problem is of major importance to the organization

- Reasonable scope—doable in 4-6 months

- The importance is clear to the organization

- Clear quantitative measures of success

- The project has the support and approval of the management

Without these attributes, the project has little chance of being successful in the short term or sustainable in the long term.

How to Select the Right Lean Six Sigma Green Belt Project?

A measurable effect on the Output (or Y)

A Lean Six Sigma Green Belt project should have a measurable effect on the Output (or Y). That effect must be initially determined in a well-developed Lean Six Sigma Charter “Goal Statement”. For example, a goal statement on a charter might read “Increase fill height capability (PpK) on line 5 filler from .82 to company target of 1.42 by December 20XX”. The difference between the current unimproved state (Ppk .82) and goal (1.42) can be correlated to an increase in value to the organization. This increase should then have a direct effect on an organizational Key Performance Indicator (or KPI).

We should not “already know the solution”

When selecting the Lean Six Sigma Green Belt project, we should not “already know the solution” to the problem. A good Lean Six Sigma project has a solution that must be discovered through the process of analysis in the Analyze phase of the DMAIC roadmap.

Understand the Output (the “Y”) in measurable terms

We should understand the Output (the “Y”) in measurable terms. For example, if something is a defect or not a defect, do we know exactly what separates the good from the bad? Is this a subjective measurement that could be interpreted differently by different operators? Do we have upper and/or lower specifications and a target?

We should have measurable and controllable inputs (X’s)

We should have measurable and controllable inputs (Xs). For a Lean Six Sigma Green Belt Project, these measurable and controllable inputs (X’s) can be Discrete data and/or Variable data. For example, a process to fill a bottle full of a liquid could have the following “X’s”: Fill Date (Discrete), Fill Time (Discrete), Fill Operator (Discrete), Fill Height (Variable), Fill Weight (oz.) (Variable), Fill Liquid Pressure (Variable), etc. These measurable inputs (X’s) combine to produce an Output (Y): Some Measure of Good or Bad. The “Y” could also be a measure of Capability using PpK.

We need to be able to statistically analyze the data

This past data should be collected to populate a multi-vari sheet. For example, a Multi-Vari Sheet could be an Excel spreadsheet where each row has a measurement for each of the “X’s” and each “Y” (if more than one “Y”).

In our “Bottle Filling” scenario, each time a bottle is filled, there should be a measurement for each “X” that creates the “Y.” If we take a sample of one hundred bottles, we should have one hundred rows of data. This data helps us to do hypothesis testing as well as other statistical analyses to understand the true nature of the process.

We need to know the specifications of the inputs

In a Green Belt Project, once discover the Key Process Input Variables (KPIVs), we might find that we do not know what specifications would optimize the KPIVs.

For example, if we find that Fill Liquid Pressure is a KPOV but we do not know the Optimum Pressure Tolerance (Upper Spec Limit, Target, and Lower Spec Limit) to get an Optimum Product (Output “Y”) then we can use a Design of Experiments (D.O.E.) to find the Optimum Pressure Tolerance.

Questions to Ask When Identifying a Six Sigma Project

Wouldn’t it be great to have a checklist to help you determine if a potential Lean Six Sigma Green Belt project is a “good” project? Below are the questions you should ask when Identifying a Lean Six Sigma Green Belt Project:

- Does this process problem negatively affect a Key Performance Indicator (or KPI)? (the answer should be “Yes”)

- What is the baseline performance in a metric?

- What is the goal (in a metric)?

- What is/are the defect(s)?

- Can you describe what makes the products/services defects?

- Do you already know the solution? (the answer should be “No”)

- Can you identify the inputs that affect performance? (the answer should be “Yes”)

- Can you measure the inputs that affect performance? (the answer should be “Yes”)

- Do you presently have historical data on the inputs that affect performance? (the answer should be “Yes”)

- Do you have access to the data on the inputs that affect performance? (the answer should be “Yes”)

- Do you have control over the inputs that affect performance? (the answer should be “Yes”)

- How quickly does the data the team will use to analyze the process populate? *Data that populates slowly (for example, one data point per week or per month) will take much longer to complete.

If you do not have the answers to the questions, then this is not presently a “good” Lean Six Sigma project to initiate. That doesn’t mean it is not a “good” project candidate. If you don’t have the right answers to these questions, table the project and find the right answers.

More warning signs of a “bad” Lean Six Sigma Green Belt project

Now that we have a better understanding of the questions to ask when identifying a “good” project, let’s show some more characteristics of a “bad” project.

Projects that should not be identified as a Lean Six Sigma Project

- Projects are used to justify a solution already in place.

- Projects in which we already know the solution.

- Projects that do not focus on the reduction of defects.

- Projects to move equipment, departments, or facilities (these are PM projects).

- Projects that we do not know the customer requirements.

- Projects that we do not know the baseline (in a metric).

- Projects that we do not know the goal (in a metric).

- Projects in which we have no historical data.

- Projects that do not directly affect a Key Performance Indicator (KPI).

- Projects that are too large in scope.

- Projects that the data do not populate rapidly. *Data that populates slowly (for example, one data point per week or per month) will take much longer to complete.

Conclusion

Project selection is a critical part of the continuous improvement effort. Like other Lean Six Sigma tools, project selection should be quantifiable, based on objective data, and not subjective guesswork. A successful project should lead to cost savings, improvements in quality, and added capacity. It can also be used to satisfy the needs of shareholders. There are key attributes of a project candidate that will result in a higher probability of success. There are also key attributes of a project candidate that will result in failure.

There are many more benefits of pursuing Six Sigma Green Belt Certification in USA. It draws out the hidden skills and increase your market value that can be much beneficial for the future.