Estimated reading time: 7 minutes

What Is Standard Work?

Standard work can include many elements such as the operator procedures, key steps, work locations, machine or technology used, production sequence, safety concerns, quality checks, and work locations. It also indicates the inventory location and quantity within the system. The standard work visual (leader standard work), also known as a standard layout, shows the operator’s movement range and product flow path. It includes information about the operation cycle time as well as the TAKT times for each product.

The standard work should be documented and presented in its entirety. It should also demonstrate the desired properties of any work performed. It is essential to document the standard work to keep the system repeatable and predictable. Non-documented systems are less likely than those that follow best practices.

What Is Standardization?

Standardization is the process of developing, promoting, and implementing technical standards to ensure that products, services, and systems meet certain criteria for quality, safety, interoperability, and efficiency. These standards provide a common set of guidelines or specifications that facilitate consistency and compatibility across different processes or products within an industry or field. Standardization can occur at various levels, including national, regional, or international standards bodies.

Key aspects of standardization include:

- Specifications: Standards define the technical specifications and requirements for products, services, or systems. These specifications could include dimensions, materials, performance criteria, testing methods, and more.

- Interoperability: Standards often aim to ensure interoperability, meaning that products or systems from different manufacturers can work together seamlessly. This is particularly important in industries where compatibility is crucial, such as technology, telecommunications, and transportation.

- Quality Assurance: Standards contribute to quality assurance by setting benchmarks and criteria that products and processes must meet. Adhering to standards can help organizations achieve consistent and high-quality results.

- Safety and Compliance: Many standards are developed to enhance safety by establishing guidelines for the design, manufacturing, and use of products. Compliance with these standards is often required by regulatory bodies.

- Simplification and Efficiency: Standardization simplifies processes by providing a common framework, which can lead to increased efficiency in manufacturing, operations, and communication.

- International Trade: Harmonized standards facilitate international trade by providing a common set of rules that businesses around the world can follow. This helps eliminate technical barriers to trade.

Standards can be developed by various organizations, including government agencies, industry associations, and international standards bodies. Some well-known international standards organizations include the International Organization for Standardization (ISO), the International Electrotechnical Commission (IEC), and the International Telecommunication Union (ITU).

The 3 Elements of Standard Work

Standard Work consists of three elements that define the requirements to meet customer demand and create stability.

Element 1.- Work Sequence

The steps that operators must complete within TAKT time and in the correct order.

Element 2.- Standard Inventory or In-Process Stock

Minimum number of parts and materials required to operate the process.

Element 3.- TAKT or PITCH Time

The rate at which services, products, or parts must be produced to meet customer demand.

This simple equation can be used to calculate takt time:

TAKT time = Net Available Time per day / Customer Demand per day

Benefits of Standard Work

Help Your People

Sometimes operators believe that because their work is so varied, it cannot be standardized or that they will have to work in monotony if they are not standardized. It is the reverse: standard work increases efficiency and allows for more creative work.

Operators can also use standardized work to organize their work. This reduces stress and relieves operators from the pressure of incorrectly performing tasks.

Standardized work also makes it easier to train new employees, as it documents how to do each process.

Improves Continuous Improvement

Kaizen is another LEAN principle. It’s the idea of continuous improvement. Kaizen is based on standard work. It is possible to objectively evaluate changes only when procedures are documented and standardized. As standards improve, this is the new standard for Kaizen. This will allow for further improvements. It’s a never-ending process to improve standard work.

It is more difficult for operators to spot 8 Lean Manufacturing wastes when they perform different tasks. It is easier to identify opportunities for improvement when processes are consistent.

Variability is Reduced

Leader Standard work decreases variation in output by standardizing the most efficient ways to do processes. It is possible to predict the outcome4 of work: costs, quality, inventory requirements, and delivery times.

6 Steps to Achieve Standard Work

Step 1: Collect data about your current operations

Establishing your TAKT or PITCH time and work order is the first step. Consistently, metrics such as the cycle time and step times per operator are recorded. Companies have real-time visibility of their operations. This allows them to see exactly what tasks are being completed.

Step 2: Take note of variations and problems

There are often multiple ways to accomplish a task. However, only one uses information, resources-materials, and machines in the most efficient manner possible.

Look at the data that you have collected and note any variations. Do you see workers who do the same job but produce different results? Do some workers take longer than Takt? Can some tasks be combined? Are there safety or quality concerns?

Step 3: The most efficient way to manage your operations

You can use LEAN tools to optimize the flow of your work and improve your processes. You could use value stream mapping or poka-yoke to error-proof your processes.

Step 4: Everything should be documented

This can be done in many ways. They guide operators through the process step by step. Operators can follow work instructions according to current best practices.

Step 5: Your training programs can be adapted

Employees must be able to understand and follow the new procedures. Re-training existing workers may be necessary. You also want to ensure that the new operator training programs you create are based on your existing work.

Step 6: Continuously improve the standard

A common mistake is to believe that once you have established standardized work, it is done. You should instead strive to improve the standard. It is much easier to spot abnormalities and problems once a standard work process has been established. Root-cause analysis is performed for each problem.

Standardized work is not always perfected or final. It is a best practice and should be challenged daily with Kaizen.

Three Basic Forms Used in Standard Work

In creating leader standard work, three basic forms are used. These forms are used by managers, engineers, and supervisors on the front lines to design the process, and by operators to improve their jobs.

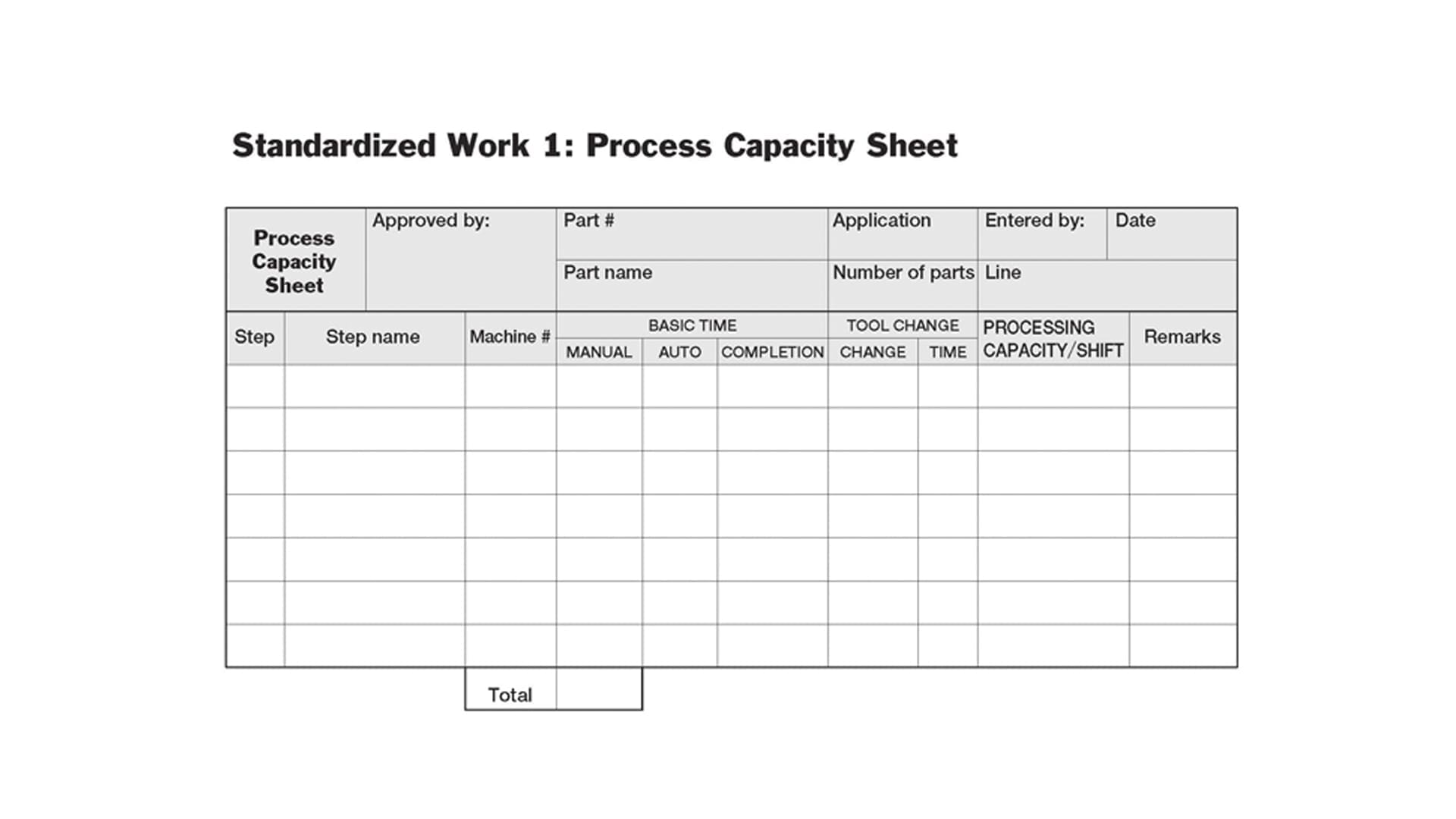

Process Capacity sheet

This standard work example calculates the machine’s capacity in a linked set (often a single cell), to verify true capacity and identify and eliminate bottlenecks. This form calculates factors such as machine cycle times tool setup and change intervals. It also includes manual work times.

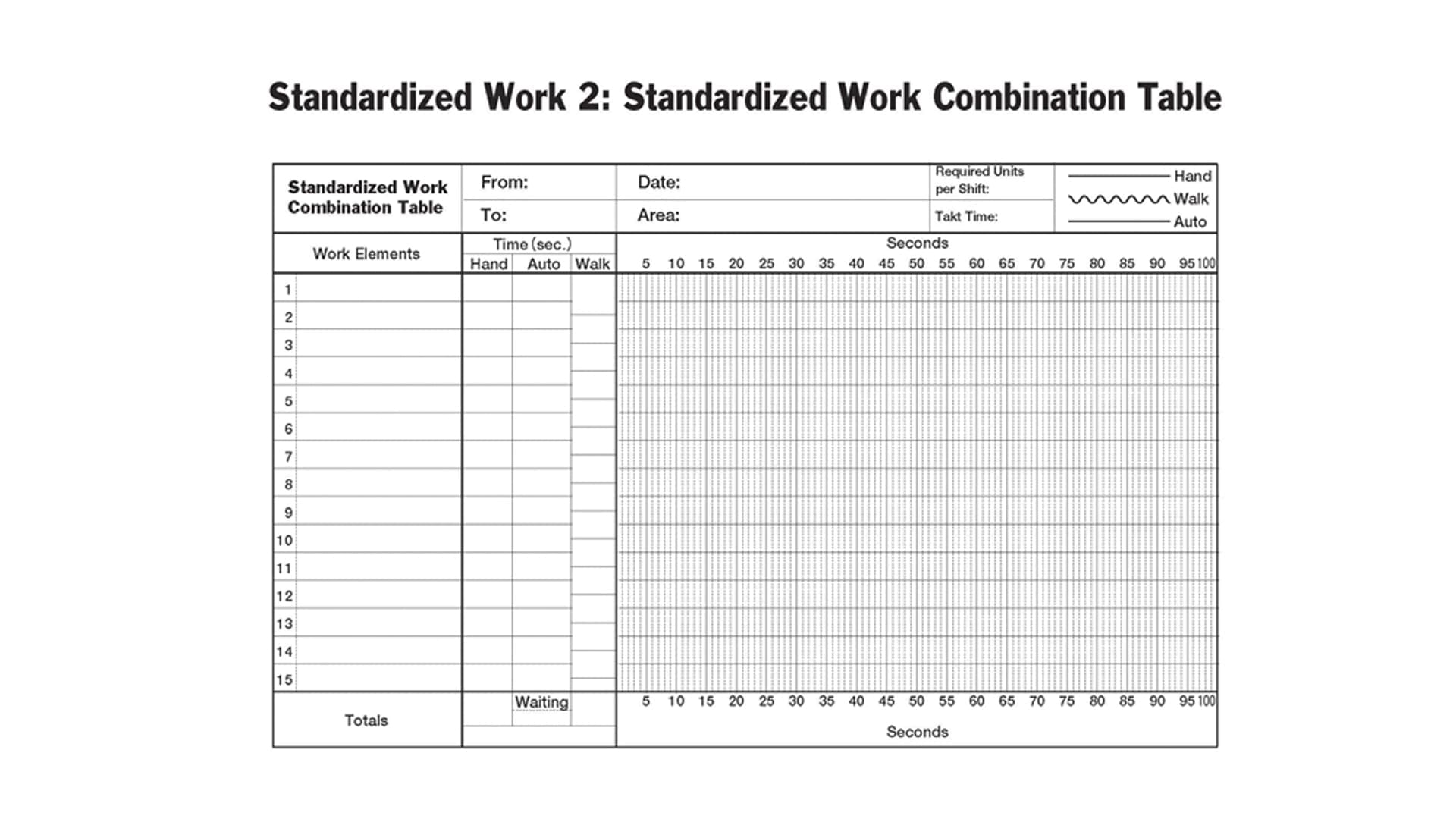

Standardized Work Combination Table

This form displays the total time taken by each operator to complete a particular production sequence. It also shows walk time and machine processing times. This form is more detailed and provides a better process design tool than operator balance charts. This table allows for the calculation of operator work content and the interaction between machines and operators in a process.

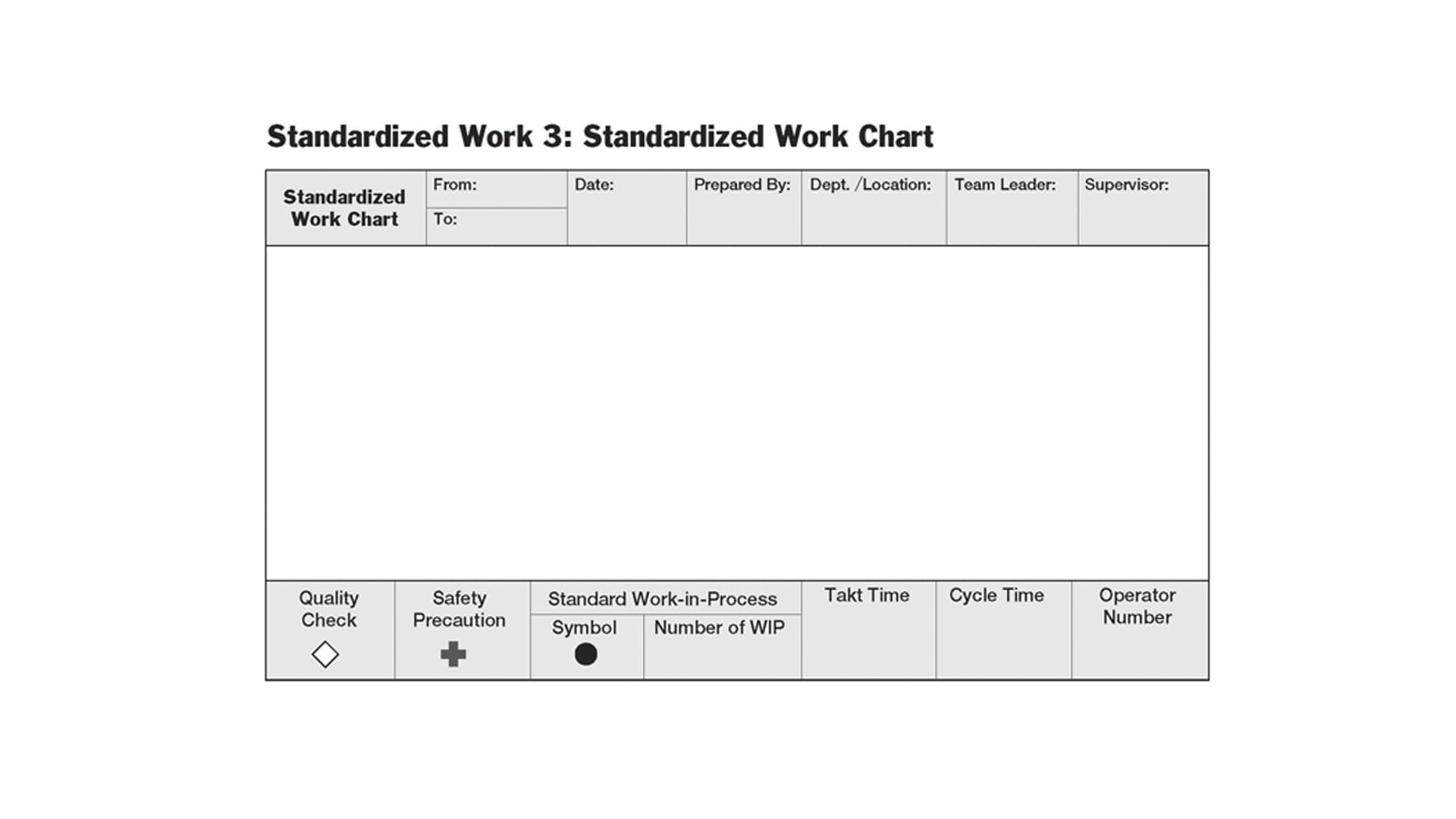

Standard Work Chart

This form displays operator movements and material locations of the machine. It also shows the overall process layout. To ensure smooth operation, the form must show three elements that make up a leader’s standard work: the current takt (and cycle) time for the job, the work sequence, and the required standard in-process inventory. As a visual tool for kaizen and visual management, standardized work charts are often displayed at workstations.