Lean Six Sigma is a methodology that combines Lean’s focus on eliminating waste with Six Sigma’s emphasis on reducing process variation, specifically to drive continuous process improvement.

When organizations implement Lean Six Sigma for process improvement, they streamline workflows, reduce costs, and improve output quality, enabling them to meet customer demands better and sustain competitive advantage. Below is an in-depth exploration of how Lean Six Sigma improves processes across industries, detailing principles, techniques, and tools that help achieve these improvements.

Table of contents

- Introduction to Lean Six Sigma for Process Improvement

- Lean Six Sigma Tools for Process Improvement

- Steps for Implementing Lean Six Sigma in Process Improvement

- Techniques Specific to Process Improvement

- Industry-Specific Applications

- Benefits

- Challenges in Implementing Lean Six Sigma for Process Improvement

- Final Words

- Related Articles

Introduction to Lean Six Sigma for Process Improvement

Lean Six Sigma aims to maximize efficiency and quality by focusing on two fundamental goals in process improvement:

- Eliminating Waste: Lean principles identify and remove non-value-added activities, helping organizations improve speed and reduce costs.

- Reducing Variation: Six Sigma techniques use statistical methods to minimize process variability, ensuring a consistent and high-quality output.

These goals work in harmony to create leaner, more efficient, and higher-quality processes that meet customer needs effectively.

Core Principles

The success of Lean Six Sigma in process improvement lies in its structured approach and adherence to five core principles:

- Customer-Centric Focus: Processes should add value from the customer’s perspective. This focus on value ensures that every step in a process serves a purpose directly or indirectly tied to customer satisfaction.

- Identification and Removal of Waste: Lean identifies seven types of waste—overproduction, waiting, transportation, excess inventory, unnecessary motion, over-processing, and defects. Reducing these wastes leads to faster processes with fewer delays.

- Variation Reduction: Six Sigma seeks to reduce inconsistencies in processes by controlling variation, leading to predictable, high-quality outputs. Reducing variation helps processes run smoothly, with less rework and fewer mistakes.

- Employee Empowerment: Lean Six Sigma encourages employees at all levels to identify inefficiencies and suggest improvements. Involving the people who work with processes daily often reveals hidden opportunities for improvement.

- Continuous Improvement: Lean Six Sigma encourages an ongoing culture of improvement. Regular, incremental changes rather than radical shifts help maintain momentum and make improvements sustainable.

Lean Six Sigma Tools for Process Improvement

Lean Six Sigma offers various tools specifically designed to aid in process improvement. Each tool targets a specific aspect of a process to improve efficiency, quality, or both.

a. DMAIC Framework

The DMAIC (Define, Measure, Analyze, Improve, Control) framework is the backbone of Six Sigma and serves as a structured, step-by-step approach for improving processes:

- Define: Clearly define the problem, objectives, and project goals. This phase establishes project boundaries and aligns the team with customer needs.

- Measure: Collect data on current process performance to establish a baseline. Precise data helps identify bottlenecks and quantify inefficiencies.

- Analyze: Identify the root cause of process inefficiencies. This step involves using data-driven tools, such as cause-and-effect analysis, to understand why a process isn’t meeting objectives.

- Improve: Implement solutions to eliminate root causes, focusing on creating streamlined, waste-free processes.

- Control: Establish monitoring practices to sustain improvements over time, ensuring that processes remain optimized and efficient.

b. 5S for Workplace Organization

5S (Sort, Set in order, Shine, Standardize, and Sustain) is a Lean tool that enhances workplace organization:

- Sort: Remove unnecessary items from the workspace.

- Set in order: Arrange tools and materials for easy access.

- Shine: Keep the work area clean and functional.

- Standardize: Establish standard procedures for organization.

- Sustain: Ensure that these practices become habitual.

It helps to create a streamlined environment, reducing waste related to motion and searching for items, ultimately contributing to process efficiency.

c. Value Stream Mapping (VSM)

Value Stream Mapping visualizes each step in a process, making it easier to spot and eliminate waste. VSM identifies the flow of materials and information needed to bring a product or service from start to finish, providing a bird’s-eye view of the entire process and pinpointing areas where delays or redundancies occur.

d. Root Cause Analysis (RCA)

RCA is critical for identifying the true cause of process problems, often using methods such as the 5 Whys and Fishbone Diagram (Ishikawa Diagram). Understanding root causes prevents addressing only symptoms and enables sustainable improvements.

e. Kaizen for Continuous Improvement

Kaizen promotes a culture of continuous improvement through small, incremental changes. Rather than aiming for large, disruptive shifts, Kaizen encourages consistent, manageable improvements that collectively result in significant process enhancements.

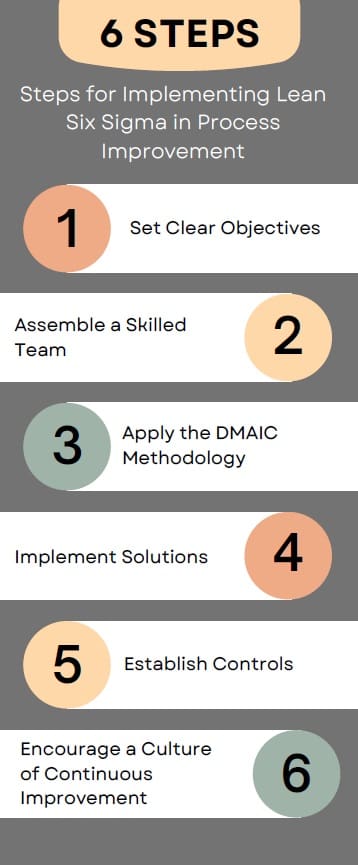

Steps for Implementing Lean Six Sigma in Process Improvement

A structured approach to implementing Lean Six Sigma is essential to achieving meaningful process improvements. Here are key steps to ensure successful implementation:

- Set Clear Objectives: Define what the improvement project aims to achieve in terms of process speed, cost reduction, quality, or customer satisfaction.

- Assemble a Skilled Team: Include team members who understand the process and the tools of Lean Six Sigma. Typically, a team consists of Green Belts or Black Belts with Lean Six Sigma expertise.

- Apply the DMAIC Methodology: Use the DMAIC framework to guide the project. Each phase should be well-defined and executed with the appropriate tools to ensure the project stays focused and efficient.

- Implement Solutions: Implement changes in a controlled environment, monitor their impact, and adjust as needed to achieve desired results.

- Establish Controls: Develop metrics and monitoring systems to ensure improvements are maintained over time, preventing backsliding and reinforcing new standards.

- Encourage a Culture of Continuous Improvement: Promote an environment where employees at all levels can contribute ideas and improvements, ensuring that the process remains efficient and effective.

Techniques Specific to Process Improvement

- Process Mapping: Visual representation of the steps in a process to identify waste and opportunities for improvement.

- SIPOC Diagrams: Helps outline the process in terms of suppliers, inputs, process, outputs, and customers, providing a high-level view.

- Flowcharts: Detailed diagrams that illustrate each step in a process, aiding in understanding the sequence and identifying bottlenecks.

- Histogram: A graphical representation of data distribution to analyze variations in process performance.

- Control Charts: Used to monitor the process over time, helping identify trends or deviations that require attention.

- Failure Mode and Effects Analysis (FMEA): A systematic approach to identifying potential failure points in a process and their impacts.

Industry-Specific Applications

Lean Six Sigma’s adaptability makes it useful across various industries, each with specific applications tailored to industry requirements.

- Manufacturing: Lean Six Sigma is widely used to streamline production lines, reduce lead times, and improve product quality. By minimizing defects and ensuring standardized processes, manufacturing companies can reduce costs and improve delivery times.

- Healthcare: In healthcare, Lean Six Sigma helps improve patient flow, reduce wait times, and optimize resource allocation. For example, in hospitals, Lean Six Sigma can streamline patient admissions and discharge processes, improving overall patient care.

- Financial Services: Banks and financial institutions use Lean Six Sigma to accelerate processes like loan approvals and payment processing, enhancing customer experience and operational efficiency.

- Retail: Lean Six Sigma is applied to inventory management, demand forecasting, and supply chain optimization. By reducing stockouts and improving logistics, retail companies can improve service quality and reduce operational costs.

- Information Technology: IT departments use Lean Six Sigma to streamline software development, testing, and project management processes. Techniques like error-proofing reduce bugs and improve project timelines, leading to more reliable software delivery.

Benefits

Implementing Lean Six Sigma for process improvement brings significant benefits:

- Reduced Waste: By eliminating non-value-adding activities, organizations reduce costs and improve efficiency.

- Improved Quality: Lean Six Sigma reduces process variation, ensuring consistent and high-quality outputs.

- Enhanced Customer Satisfaction: Faster, more reliable processes lead to better customer experiences and increased satisfaction.

- Increased Profitability: Efficient processes with fewer defects and wastes lead to reduced costs and higher profitability.

- Better Resource Utilization: Lean Six Sigma optimizes resources, ensuring that time, labor, and materials are used effectively.

Challenges in Implementing Lean Six Sigma for Process Improvement

Lean Six Sigma implementation can encounter obstacles:

- Resistance to Change: Employees may be hesitant to adopt new processes, requiring clear communication and change management strategies.

- Resource-Intensive Training: Effective Lean Six Sigma implementation requires skilled practitioners, which involves significant training and investment.

- Sustaining Improvements: Maintaining momentum post-implementation can be challenging, making ongoing monitoring essential.

Final Words

Lean Six Sigma provides a comprehensive framework for process improvement, combining waste reduction with quality enhancement. Its structured approach, built around the DMAIC framework and supported by tools like Value Stream Mapping, 5S, and Kaizen, ensures that processes are streamlined and aligned with organizational goals.

By embracing Lean Six Sigma, companies not only improve operational efficiency but also cultivate a culture of continuous improvement that drives long-term success.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.