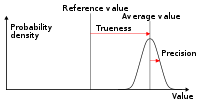

In a set of measurements, accuracy is closeness of the measurements to a specific value, while precision is the closeness of the measurements to each other.

Accuracy has two definitions:

- More commonly, it is a description of systematic errors, a measure of statistical bias; low accuracy causes a difference between a result and a “true” value. ISO calls this trueness.

- Alternatively, ISO defines accuracy as describing a combination of both types of observational error above (random and systematic), so high accuracy requires both high precision and high trueness.

Precision is a description of random errors, a measure of statistical variability.

In simpler terms, given a set of data points from repeated measurements of the same quantity, the set can be said to be accurate if their average is close to the true value of the quantity being measured, while the set can be said to be precise if the values are close to each other. In the first, more common definition of “accuracy” above, the two concepts are independent of each other, so a particular set of data can be said to be either accurate, or precise, or both, or neither.

Quantification

In industrial instrumentation, accuracy is the measurement tolerance, or transmission of the instrument and defines the limits of the errors made when the instrument is used in normal operating conditions.

Ideally a measurement device is both accurate and precise, with measurements all close to and tightly clustered around the true value. The accuracy and precision of a measurement process is usually established by repeatedly measuring some traceable reference standard. Such standards are defined in the International System of Units (abbreviated SI from French: Système international d’unités) and maintained by national standards organizations such as the National Institute of Standards and Technology in the United States.

This also applies when measurements are repeated and averaged. In that case, the term standard error is properly applied: the precision of the average is equal to the known standard deviation of the process divided by the square root of the number of measurements averaged. Further, the central limit theorem shows that the probability distribution of the averaged measurements will be closer to a normal distribution than that of individual measurements.

With regard to accuracy we can distinguish:

- the difference between the mean of the measurements and the reference value, the bias. Establishing and correcting for bias is necessary for calibration.

- the combined effect of that and precision.

A common convention in science and engineering is to express accuracy and/or precision implicitly by means of significant figures. Where not explicitly stated, the margin of error is understood to be one-half the value of the last significant place. For instance, a recording of 843.6 m, or 843.0 m, or 800.0 m would imply a margin of 0.05 m (the last significant place is the tenths place), while a recording of 843 m would imply a margin of error of 0.5 m (the last significant digits are the units).

A reading of 8,000 m, with trailing zeros and no decimal point, is ambiguous; the trailing zeros may or may not be intended as significant figures. To avoid this ambiguity, the number could be represented in scientific notation: 8.0 × 103 m indicates that the first zero is significant (hence a margin of 50 m) while 8.000 × 103 m indicates that all three zeros are significant, giving a margin of 0.5 m. Similarly, one can use a multiple of the basic measurement unit: 8.0 km is equivalent to 8.0 × 103 m. It indicates a margin of 0.05 km (50 m). However, reliance on this convention can lead to false precision errors when accepting data from sources that do not obey it. For example, a source reporting a number like 153,753 with precision +/- 5,000 looks like it has precision +/- 0.5. Under the convention it would have been rounded to 154,000.

Alternatively, in a scientific context, if it is desired to indicate the margin of error with more precision, one can use a notation such as 7.54398(23) × 10−10 m, meaning a range of between 7.54375 and 7.54421 × 10−10 m.

Precision includes:

- repeatability — the variation arising when all efforts are made to keep conditions constant by using the same instrument and operator, and repeating during a short time period; and

- reproducibility — the variation arising using the same measurement process among different instruments and operators, and over longer time periods.

ISO definition (ISO 5725)

According to ISO 5725-1, the general term “accuracy” is used to describe the closeness of a measurement to the true value. When the term is applied to sets of measurements, it involves a component of random error and a component of systematic error. In this case trueness is the closeness of the mean of a set of measurement results to the actual (true) value and precision is the closeness of agreement among a set of results.

ISO 5725-1 and VIM also avoid the use of the term “bias“, previously specified in BS 5497-1, because it has different connotations outside the fields of science and engineering, as in medicine and law.

References

Wikipedia. Accuracy and Precision. https://en.wikipedia.org/wiki/Accuracy_and_precision