SMED stands for Single-Minute Exchange of Dies. It is a revolutionary management technique developed by Shigeo Shingo, a Japanese industrial engineer. The essence of SMED is to reduce the time required to changeover a production process, particularly the die change in manufacturing operations, to less than 10 minutes.

The core principle is to optimize the changeover time by improving efficiency and minimizing machine idle time. This technique is especially valuable for industries that rely on expensive and modern machines where downtime can significantly affect productivity and costs.

In real-world applications, the goal of SMED is to minimize any interruptions in production. Since modern equipment tends to be more expensive and advanced, reducing downtime is critical for maintaining profitability. SMED helps organizations utilize these machines to their fullest potential, thereby reducing costs associated with stoppages and enhancing overall productivity.

Table of contents

What is SMED?

SMED stands for Single-Minute Exchange of Die, a concept developed by Shigeo Shingo in the 1950s at the Toyo Kogyo factory (which later became Mazda). The goal of SMED is to reduce setup times to less than 10 minutes, with the name “Single-Minute” referring to the ambition of reducing setup time to a single digit number of minutes.

This methodology focuses on reducing the time and resources required to change over equipment. It aims to streamline the transition from one production run to another.

Setup processes are crucial because they directly affect the availability and efficiency of machinery. In traditional manufacturing setups, operators stop machines for extended periods of time. They reconfigure the machines for the next batch during this downtime.

These “changeover times” can be significant — sometimes taking over an entire day. SMED offers a way to reduce this downtime, thus improving overall equipment efficiency (OEE).

Basic Setup Process

Before we dive into how SMED works, it’s essential to understand what makes up a typical setup process. A setup generally consists of four stages:

- Prepare, Adjust, and Check: In this phase, tools and materials are gathered to ensure everything needed for the setup is available.

- Remove Old Tooling and Install New Tooling: Operators remove the current dies, molds, or tooling from the machine. They then install new ones for the next production run.

- Measure, Set, and Calibrate: The operators perform any necessary adjustments to the machine’s settings or calibration. This ensures the machine is ready to produce high-quality parts.

- Produce Initial Parts and Adjust: This stage involves running some initial trial parts, adjusting as needed, and ensuring the machine is functioning correctly before full production starts.

Each of these stages can take varying amounts of time, depending on the complexity of the equipment and the skill of the operators. In some cases, setup tasks may be manual and time-consuming, adding up to long changeover times.

Why SMED Was Developed?

During the 1960s, setup times in industries like automotive manufacturing were incredibly long. For instance, a large stamping press used for automotive parts could require a full day or more for setup, which was a major bottleneck in the production process. Shigeo Shingo recognized that reducing this setup time could lead to significant increases in manufacturing capacity, leading him to develop the SMED methodology.

SMED focuses on reducing setup times. It allows machines to quickly reconfigure for new batches of products without causing significant delays. The result is that manufacturers can operate more flexibly and cost-effectively, with less downtime and more throughput.

Importance of SMED in Lean Manufacturing

SMED is an essential part of lean manufacturing, which focuses on eliminating waste and improving overall efficiency. In the context of SMED, “waste” refers to unnecessary time spent during setup and changeover processes.

By reducing the time it takes to switch from one production task to another, companies can achieve faster production cycles, better use of resources, and greater flexibility in meeting customer demands.

A key principle of SMED is the separation of “external” and “internal” activities during the changeover process. External activities are those tasks that can be performed while the machine is running. These include preparing tools or materials for the next production batch. Internal activities, on the other hand, can only be done when the machine is stopped. These tasks include swapping out a die or recalibrating equipment.

By converting internal activities into external ones, SMED aims to reduce the total time required for a changeover. This approach focuses not only on speeding up the physical task of changing dies or components but also on streamlining the planning and preparation process. The goal is to ensure that every minute of machine time is maximized.

Three Phases of SMED Implementation

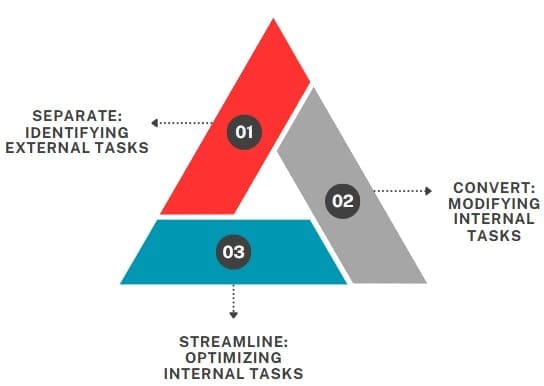

SMED implementation is built upon three essential stages: Separate, Convert, and Streamline. These phases help systematically reduce changeover times by identifying opportunities to perform tasks externally, removing unnecessary steps, and optimizing those that remain. The process is iterative and aims for continuous improvement in each cycle.

- Separate: Identifying External Tasks

The first stage of SMED involves identifying the activities that can be done while the equipment is still running. In a typical production environment, some tasks must be performed while the machine is idle. However, many tasks can actually be completed while production is ongoing.

During the “Separate” phase, operators examine every task involved in the changeover. They determine which tasks can be shifted outside the stoppage period. Common examples include:- Preparing tools, materials, and instructions in advance.

- Cleaning parts or tools before or after the changeover process.

- Conducting quality checks on parts produced during the previous run.

The goal in this phase is to ensure that the changeover process starts with everything already in place, minimizing the need for time-consuming actions once the machine stops.

- Convert: Modifying Internal Tasks

The second stage focuses on modifying tasks that were previously internal (requiring the machine to be stopped) into external tasks. If certain activities cannot be performed externally, the next best option is to modify them so they can be done while the equipment is still running.

The “Convert” phase involves looking for innovative ways to modify the setup process. For example:- Preparing parts before the changeover starts (such as preheating dies).

- Using quick-change jigs that allow parts to be swapped out without requiring the machine to be stopped.

- Modularizing equipment, so entire components or parts can be swapped in and out quickly without adjustment.

Converting internal tasks into external ones helps reduce the actual stoppage time, making the transition between product types more seamless.

- Streamline: Optimizing Internal Tasks

The final stage in the SMED process is the “Streamline” phase, where remaining internal tasks are analyzed for further optimization. These tasks are crucial to completing the changeover but still require the machine to be idle. In this phase, companies aim to minimize the time spent on these activities, either by eliminating unnecessary steps or finding ways to complete them faster.

Techniques for streamlining can include:- Replacing bolts with quick-release mechanisms to speed up disassembly and assembly.

- Standardizing settings so that adjustments can be made faster.

- Organizing tools and parts in a way that minimizes unnecessary movement.

- Creating parallel operations where multiple team members work simultaneously on different aspects of the changeover.

The Streamline phase also encourages continuous monitoring and improvement. Over time, the process should become more efficient, with each subsequent pass reducing the changeover time further.

Benefits of SMED

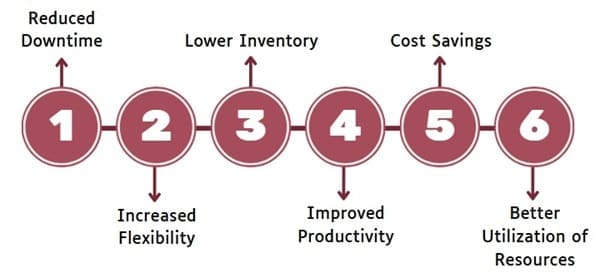

The implementation of SMED has numerous benefits, particularly for industries that experience high levels of variability in production and demand. Some of the primary benefits of using SMED include:

- Reduced Downtime: By minimizing the time spent on changeovers, machines are available for production for longer periods, which translates to higher overall output.

- Increased Flexibility: Shorter changeover times allow manufacturers to switch between different products more quickly, which is essential in industries that need to respond to changing customer demands or market conditions.

- Lower Inventory: With faster changeovers, manufacturers can produce smaller batches and reduce the need for large amounts of work-in-progress inventory, leading to a more efficient production process.

- Improved Productivity: SMED enhances machine availability and reduces idle time, resulting in better utilization of equipment and a higher return on investment (ROI).

- Cost Savings: By reducing setup times, companies can avoid the costs associated with machine downtime and unnecessary labor, contributing to overall cost savings.

- Better Utilization of Resources: SMED helps maximize the use of both human and machine resources, ensuring that production operations are running as efficiently as possible.

Also See: Lean Six Sigma Certification Programs, Winston-Salem, North Carolina

SMED Process

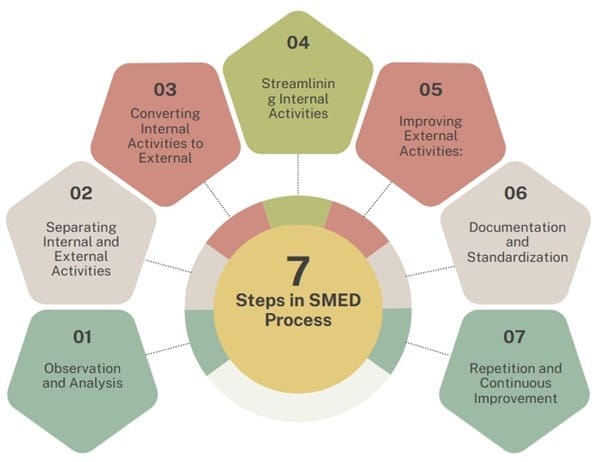

The process of implementing SMED involves these steps:

- Observation and Analysis: The first step is to observe the current setup process. Operators record the time spent on each element of the changeover. They identify which activities are internal, those that can only be done when the machine is stopped, and which are external, those that can be done while the machine is running.

- Separating Internal and External Activities: After documenting the current process, operators classify tasks into internal and external categories. External activities can often be performed while the machine is still running, whereas internal activities must wait until the machine is stopped.

- Converting Internal Activities to External: The next step is to convert as many internal activities as possible into external ones. For example, preparing tools and materials in advance or setting up equipment while the machine is still running can significantly reduce changeover time.

- Streamlining Internal Activities: For activities that must be performed while the machine is stopped, the next step is to simplify them. This might involve rethinking the sequence of tasks, improving tools or equipment, or implementing standard operating procedures to make the tasks quicker and more efficient.

- Improving External Activities: After streamlining internal activities, attention is turned to improving external activities. This might involve ensuring that all materials and tools are readily available, or training employees to handle external tasks more efficiently.

- Documentation and Standardization: After making improvements, operators should document and standardize the new procedures. This ensures consistent implementation of the changes and provides a foundation for future improvements to build upon.

- Repetition and Continuous Improvement: SMED is not a one-time fix but an ongoing process. Changeover times should be monitored regularly, and opportunities for further improvements should be identified and implemented.

Challenges and Bottlenecks in Implementing SMED

While SMED can lead to significant improvements in productivity and efficiency, its implementation is not without challenges. Some of the common obstacles that organizations face when adopting SMED include:

Resistance to Change: Employees may resist changes to established processes, especially if they are unfamiliar with the benefits of SMED or fear that it will negatively impact their work.

Design Limitations: In some cases, the equipment or machinery may not support quick changeovers. If the machinery design is outdated or inefficient, implementing SMED might require a significant investment in new equipment or modifications.

Lack of Awareness or Training: Without proper training or understanding of the SMED methodology, employees may struggle to implement the technique effectively. Ensuring that everyone involved in the changeover process is properly trained is crucial to success.

Inadequate Resources: SMED requires a commitment of time and resources to thoroughly observe and analyze the changeover process. Without the necessary support, it can be difficult to carry out the required steps and make meaningful improvements.

Complexity of the Changeover Process: In some industries, the changeover process may be inherently complex or require specialized equipment. In these cases, reducing changeover times may be more challenging and require more creative solutions.

Practical Applications

While SMED was originally developed for the automotive industry, its principles have been applied successfully in a wide range of sectors. Some industries where SMED has proven particularly effective include:

- Textiles: In the textile industry, fast changeovers are crucial for maintaining flexibility and responding to changing fashion trends. By reducing the time required to switch between different fabrics or designs, SMED helps textile manufacturers remain competitive and reduce inventory.

- Food and Beverage: The food and beverage industry often faces high variability in production due to seasonal demand or changing consumer preferences. SMED allows manufacturers to switch between product types quickly, improving production flexibility and minimizing downtime.

- Pharmaceuticals: Pharmaceutical manufacturers often work with strict regulations and quality control standards. By reducing changeover times, SMED helps these companies maintain high levels of efficiency while ensuring that their processes remain compliant with regulatory requirements.

- Electronics and Consumer Goods: In industries like electronics and consumer goods, demand for new products can change rapidly. SMED helps manufacturers switch production lines quickly to meet market demand while reducing costs associated with long changeover times.

Final Words

SMED is a powerful technique for reducing changeover time, improving machine availability, and increasing production flexibility. By separating internal and external activities, simplifying processes, and streamlining operations, SMED helps organizations maximize the efficiency of their manufacturing processes with minimal investment.

Though its implementation can present challenges, the benefits of SMED in terms of cost savings, increased productivity, and improved flexibility make it an essential tool for modern manufacturers striving to stay competitive in a rapidly changing market.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.