Lean Six Sigma is a method that blends Lean (cutting waste) and Six Sigma (improving quality). It gives organizations the tools to simplify how they work, reduce errors, and make better products or services. This helps them save money and keep customers satisfied.

Many different types of companies use Lean Six Sigma to make their operations excellent. It’s a way to keep making things better using facts and data.

Table of contents

8 Companies That Use Lean Six Sigma

Let’s examine how some of the world’s most prominent companies have successfully adopted Lean Six Sigma to transform their operations:

1. General Electric (GE)

General Electric was one of the earliest and most high-profile adopters of Six Sigma, implementing it in the mid-1990s under the visionary leadership of then-CEO Jack Welch. GE’s deep integration of the methodology went beyond isolated process improvements—it became embedded in the company’s culture and leadership development programs.

GE’s application of Six Sigma principles led to billions of dollars in savings across its various divisions, which span industries from aviation and power generation to healthcare and finance. The company used tools like DMAIC (Define, Measure, Analyze, Improve, Control) to identify inefficiencies and make data-driven decisions.

For GE, the implementation wasn’t just a short-term project; it became a long-term strategic initiative that set the standard for quality and performance excellence in corporate America.

Public, Onsite, Virtual, and Online Six Sigma Certification Training!

- We are accredited by the IASSC.

- Live Public Training at 52 Sites.

- Live Virtual Training.

- Onsite Training (at your organization).

- Interactive Online (self-paced) training,

2. Motorola

Motorola is widely credited with developing the original Six Sigma methodology in 1986. Faced with increasing international competition—particularly from Japanese electronics firms—Motorola needed a robust system for improving product quality and manufacturing consistency. Six Sigma emerged as their answer.

Through rigorous application of statistical tools and defect reduction techniques, Motorola dramatically reduced variability in its manufacturing processes.

The initiative yielded impressive results, including a reduction in production costs and defects, and culminated in the company receiving the prestigious Malcolm Baldrige National Quality Award in 1988. Motorola’s pioneering work laid the foundation for countless other companies to follow in its footsteps.

Also Read: Principles of Total Quality Management

3. 3M

As a global innovation leader, 3M’s adoption of Lean Six Sigma has allowed the company to enhance its efficiency without compromising creativity. Known for iconic products like Post-it Notes and Scotch tape, 3M has used Lean Six Sigma to optimize manufacturing, improve supply chain responsiveness, and reduce product development cycle times.

Through its focus on continuous improvement, 3M has improved production yields and reduced waste, all while ensuring high standards of product quality. Its success demonstrates that Lean Six Sigma can be effectively applied in research- and innovation-heavy environments where adaptability is key.

4. Ford Motor Company

Although Ford had experience with quality initiatives such as Total Quality Management (TQM) in the 1980s, it formally embraced Six Sigma in 1999. This strategic decision came as part of a broader effort to rebuild customer trust and improve operational efficiency following a period of quality concerns and financial instability.

By applying Six Sigma to areas such as product design, manufacturing, and customer service, Ford managed to reduce variability and enhance product reliability. The result was an improvement in vehicle quality, increased customer satisfaction, and greater cost savings across its global operations.

Lean Six Sigma has since become a core part of Ford’s DNA, particularly in its drive toward sustainability and smart manufacturing.

5. Boeing

Boeing adopted Six Sigma in the early 1990s to manage the immense complexity of its aerospace manufacturing processes. In an industry where precision, safety, and reliability are non-negotiable, Lean Six Sigma provides the structure and analytical rigor needed to meet these high standards.

By integrating Lean principles with Six Sigma tools, Boeing has been able to reduce rework, improve product flow, and enhance collaboration across departments. The methodology has helped Boeing to minimize errors in aircraft assembly, improve supplier performance, and enhance time-to-market for new products, including its next-generation commercial and defense aircraft.

Also Read: What is Additive Manufacturing?

6. Amazon

Amazon’s operational success is deeply rooted in its relentless pursuit of efficiency, and Lean Six Sigma plays a significant role in achieving that. From warehouse automation to supply chain logistics and delivery optimization, Amazon employs data-driven methodologies to eliminate inefficiencies and enhance the customer experience.

The company uses Lean Six Sigma to identify process bottlenecks, reduce shipping times, minimize inventory errors, and lower fulfillment costs. In Amazon’s fulfillment centers, for instance, employees are trained to spot wasteful practices and propose improvements—supporting a culture of continuous innovation and agility.

7. Bank of America

In the service sector, Bank of America has distinguished itself through the strategic use of Lean Six Sigma to streamline financial processes, enhance customer satisfaction, and reduce operational errors. The bank’s large-scale adoption of the methodology helped it improve turnaround times, reduce defects in processes such as credit card issuance and loan approvals, and cut costs.

By leveraging Six Sigma’s DMAIC framework and Lean’s focus on process flow, Bank of America has improved its back-office functions and frontline services alike. This has contributed to both regulatory compliance and improved customer retention in a highly competitive industry.

8. McKinsey & Company

Even consulting firms like McKinsey & Company have embraced Lean Six Sigma—not just for advising clients, but for internal operations. The firm uses the methodology to improve knowledge management, standardize consulting processes, and boost project efficiency.

McKinsey’s ability to combine strategic insight with process excellence has helped it deliver more consistent and high-value solutions to clients. Its internal use of Lean Six Sigma principles also enhances decision-making, accelerates training programs, and supports global collaboration across offices.

Other Notable Companies Using Lean Six Sigma

In addition to these leading adopters, numerous other organizations have integrated Lean Six Sigma into their operational strategies, including:

- Textron: A multi-industry company that applies Lean Six Sigma in aerospace, defense, and finance to drive performance and innovation.

- Xerox: Leverages the methodology to improve document management solutions and internal service processes.

- BAE Systems: Applies Lean Six Sigma in defense manufacturing to ensure quality and regulatory compliance.

- Chevron: Uses it in energy production and refinery operations to enhance safety and reduce downtime.

- Abbott: Applies Lean Six Sigma in its medical device and pharmaceutical divisions to improve product quality and regulatory alignment.

- McKesson: Uses process improvement to streamline healthcare logistics and supply chain operations.

- Wipro: As a leading IT and consulting firm, Wipro integrates Lean Six Sigma to enhance project delivery, reduce bugs, and improve customer satisfaction.

Evolution of Lean Six Sigma

The origin of Lean Six Sigma can be traced to the convergence of two powerful approaches:

- Six Sigma, born at Motorola, focuses on reducing process variation and defects using statistical tools.

- Lean, inspired by the Toyota Production System, targets the elimination of waste and non-value-added activities to improve process flow and efficiency.

By combining these methodologies, Lean Six Sigma provides a comprehensive framework for tackling both speed and quality issues within an organization.

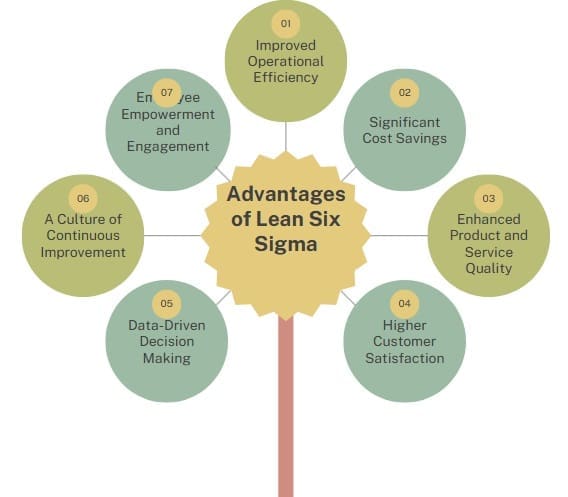

Advantages of Lean Six Sigma

Here are some of the major benefits that have driven its global adoption:

1. Improved Operational Efficiency

Lean Six Sigma eliminates redundant steps, simplifies workflows, and enhances process flow. This directly translates into faster turnaround times and more productive use of resources.

2. Significant Cost Savings

By reducing waste and defects, organizations experience dramatic reductions in production costs, overhead, and service-related expenses. Many companies report millions in annual savings through focused Lean Six Sigma initiatives.

3. Enhanced Product and Service Quality

The methodology’s emphasis on defect prevention and process control ensures that products and services meet or exceed customer expectations, increasing reliability and brand trust.

4. Higher Customer Satisfaction

As quality improves and processes become more responsive, customers benefit from better experiences. Faster service, fewer errors, and more reliable products all contribute to increased loyalty.

5. Data-Driven Decision Making

Lean Six Sigma fosters a culture of evidence-based management. By relying on data analysis to diagnose problems and validate improvements, organizations can make smarter and more sustainable decisions.

6. A Culture of Continuous Improvement

Beyond short-term fixes, Lean Six Sigma instills a long-term mindset of innovation and problem-solving. Teams are encouraged to continuously seek out new ways to enhance performance and eliminate inefficiencies.

7. Employee Empowerment and Engagement

Lean Six Sigma involves frontline employees in identifying problems and crafting solutions. This inclusive approach boosts morale, fosters collaboration, and increases job satisfaction.

Final Words

Lean Six Sigma remains one of the most impactful methodologies for organizations seeking to achieve operational excellence, elevate quality standards, and build resilient, customer-centric processes. Its widespread adoption by industry leaders across sectors—from technology and healthcare to manufacturing and finance—demonstrates its versatility and enduring relevance.

As businesses navigate the challenges of global competition, technological disruption, and evolving customer expectations, Lean Six Sigma offers a proven pathway to sustainable success. By embracing its principles, companies can transform their operations, empower their workforce, and deliver superior value—both now and in the future.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.