Operational Excellence (OpEx) is a business philosophy and methodology that aims to improve processes, reduce costs, and enhance customer satisfaction. Its origins lie in the success of the Toyota Production System (TPS), which revolutionized manufacturing in Japan and became widely adopted in Western countries during the 1980s.

While rooted in manufacturing, OpEx has since expanded into diverse industries, including finance and the public sector.

The core principle of OpEx is continuous improvement—constantly refining processes, tools, and techniques to achieve better, faster, and more efficient operations.

Table of contents

What is Operational Excellence?

Operational excellence is aligning people, processes, and technology to achieve peak organisational performance. It is a holistic framework designed to enhance productivity, quality, and customer satisfaction while minimizing waste and inefficiencies.

Operational excellence is grounded in several key principles:

- Continuous Improvement: Incremental enhancements to processes and systems.

- Customer Focus: Prioritizing customer needs and expectations.

- Leadership Commitment: A culture of accountability and proactive leadership.

- Data-Driven Decision-Making: Utilizing analytics and metrics to guide strategies.

Unlike traditional process improvement methods that focus on solving isolated problems, operational excellence emphasizes creating an ecosystem where improvements are sustained and scaled.

Defining Operational Excellence

Operational Excellence, in its simplest form, means “safely creating sustainable value.”

- Operational pertains to enterprises that produce or deliver goods or services, spanning industries such as manufacturing, energy, transportation, healthcare, and hospitality.

- Excellence implies achieving and maintaining the highest standards to ensure long-term success.

Leading organizations like Chevron, DuPont, and ExxonMobil have highlighted the importance of Operational Excellence. Their focus includes areas such as safety, risk management, efficiency, and reliability.

This philosophy not only enhances operational processes but also fosters a culture of continuous improvement and collaboration.

Key Elements of Operational Excellence

To truly achieve Operational Excellence, organizations must focus on two key areas:

Strategy and Leadership

Leadership is the cornerstone of Operational Excellence. Leaders must:

- Provide clear direction by linking OE efforts to strategic business goals.

- Focus on a few critical initiatives instead of overloading the organization with numerous programs.

- Engage employees and foster a high-performance culture where everyone understands their role and its importance.

Leaders should also avoid a superficial understanding of OE. A deep, hands-on approach ensures they can effectively guide implementation and inspire their teams.

Execution

Execution is about translating strategies into actionable results. This involves focusing on specific operational areas to gain a competitive edge. Five critical drivers of operational success are:

a. Safety

Safety ensures smooth business operations by protecting employees and assets. Beyond compliance, strong safety records can enhance a company’s reputation, especially in industries like construction and natural resources, where safety performance often influences contract awards.

b. Asset Productivity

Asset productivity measures how efficiently an organization uses its resources. Companies should optimize their asset base instead of solely relying on new investments. This includes improving facility usage, aligning operations with business cycles, and adapting to changing market demands.

c. Human Capabilities

Developing employees’ skills and retaining organizational knowledge are vital for long-term success. Organizations must address challenges like workforce ageing and rising labour costs by investing in training, knowledge retention, and productivity improvements.

d. Quality

Maintaining high product and service quality is essential for customer satisfaction and competitive positioning. Organizations should focus on reducing process variations, eliminating waste, and ensuring consistency in outputs.

e. Business Processes

Strong processes convert inputs into desired outputs efficiently. Leaders must ensure processes support the organization’s competitive advantage. Well-designed, measured, and managed processes are essential for sustained success.

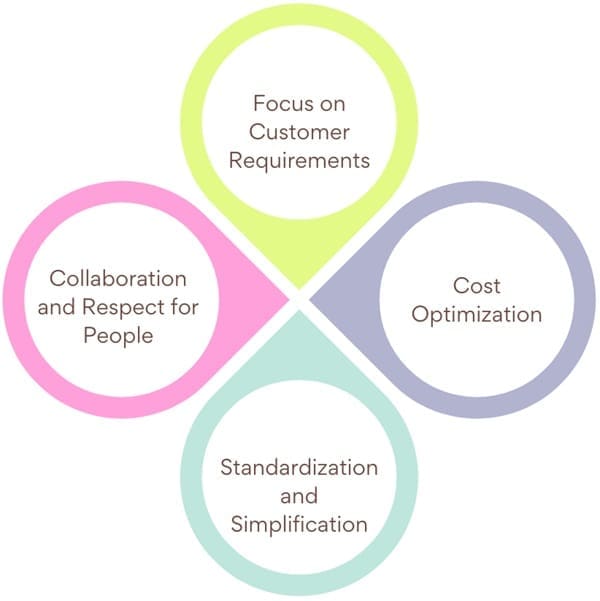

Key Principles of Operational Excellence

- Focus on Customer Requirements

Operational Excellence prioritizes customer satisfaction. Businesses must adapt to changing demands and deliver solutions that meet or exceed expectations. - Cost Optimization

Reducing unnecessary costs while maintaining quality is crucial. Streamlining processes, eliminating inefficiencies, and leveraging data-driven approaches help stabilize operations and increase profitability. - Standardization and Simplification

Clear, standardized workflows ensure consistency and minimize errors. Simplicity in processes allows teams to identify and address issues quickly. - Collaboration and Respect for People

Successful organizations foster collaboration across departments and value employee contributions. This creates an environment of trust and innovation.

Challenges in Implementing Operational Excellence

Organizations often face hurdles when adopting OpEx. Common issues include:

- Lack of Clarity: Confusion between OpEx and similar methodologies like Total Quality Management (TQM) or Business Process Reengineering (BPR).

- Insufficient Embedding: Failing to integrate OpEx into the organizational culture leads to reverting to old practices.

- Knowledge Gaps: Inadequate understanding of OpEx principles results in repeating mistakes.

Additionally, during periods of economic austerity, there’s a risk of narrowing OpEx initiatives to cost-cutting measures, which undermines long-term success.

Expanding the Scope of Operational Excellence

OpEx was initially associated with manufacturing but has proven effective across various industries:

- Financial Services: Streamlining processes and reducing operational risks.

- Public Sector: Improving service delivery and reducing inefficiencies.

- Utilities and Logistics: Enhancing supply chain efficiency and customer satisfaction.

Research indicates that organizations implementing OpEx can achieve performance improvements of 15% to 20%.

Benefits of Operational Excellence

- Increased Productivity and Quality: By simplifying workflows and eliminating redundant steps, organizations can maximize output and deliver high-quality products or services.

- Enhanced Customer Satisfaction: Meeting customer expectations consistently builds trust and loyalty. Adapting quickly to customer needs further strengthens this relationship.

- Risk Mitigation: Effective risk assessment and management are central to Operational Excellence. This ensures the safety and reliability of operations while protecting organizational assets.

- Sustainable Growth: Operational Excellence aligns resources and efforts toward long-term goals, ensuring consistent improvement and competitive advantage.

Implementing Operational Excellence

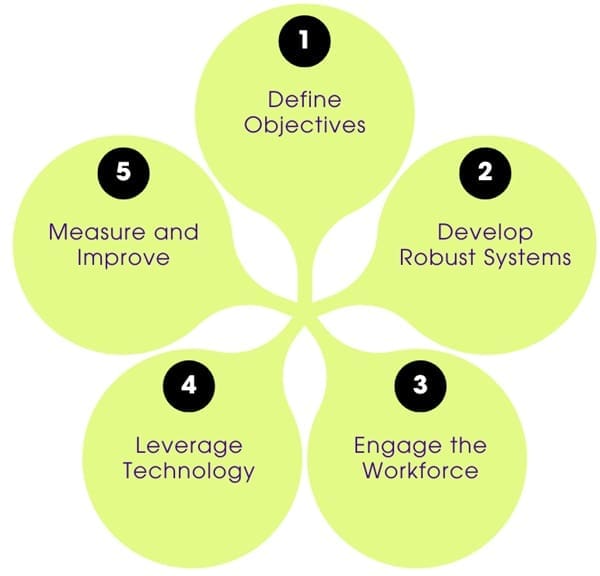

To successfully implement Operational Excellence, organizations should follow these steps:

- Define Objectives

Clearly articulate goals and how they align with the organization’s mission. For instance, a manufacturing company may aim to reduce defects, while a service provider may focus on customer response time. - Develop Robust Systems

Establish control and management systems to monitor performance. Use data-driven insights to identify areas for improvement. - Engage the Workforce

Train employees to embrace the principles of Operational Excellence. Encourage them to take ownership of processes and outcomes. - Leverage Technology

Adopt tools and technologies that streamline operations and enhance efficiency. Automation, data analytics, and real-time monitoring can play a significant role. - Measure and Improve

Regularly assess performance using key metrics. Use feedback to refine strategies and ensure continuous improvement.

Operational Excellence in Practice: Case Studies

Chevron

Chevron defines Operational Excellence as the systematic management of safety, health, environment, and efficiency. Its approach ensures reliable operations and minimizes environmental impact.

ExxonMobil

ExxonMobil incorporates Operational Excellence into its culture. By focusing on risk management and efficiency, it achieves safe, reliable, and profitable operations.

DuPont

DuPont applies proven practices in asset productivity, capital effectiveness, and operations risk management to drive business success.

Toyota Production System

Toyota is often cited as a pioneer of operational excellence. Its Lean manufacturing principles emphasize waste reduction, continuous improvement, and respect for people. Toyota’s commitment to Kaizen (continuous improvement) has set a global standard for efficiency and quality.

Amazon’s Operational Excellence

Amazon’s focus on process optimization, data-driven decision-making, and customer satisfaction has propelled it to the forefront of e-commerce. From streamlined supply chains to innovative fulfilment centers, Amazon exemplifies operational excellence.

General Electric (GE) and Six Sigma

GE’s adoption of Six Sigma under Jack Welch led to dramatic improvements in quality and cost efficiency. The methodology became a cornerstone of GE’s operational strategy, delivering billions in savings.

Sustaining Success with Operational Excellence

To make OpEx a long-term success, organizations must:

- Embed a Continuous Improvement Culture: Regularly revisit and refine processes.

- Align Leadership: Leadership must champion and sustain the OpEx mindset.

- Monitor Progress: Use measurable outcomes to track success and make adjustments.

Final Words

Operational Excellence is about excelling in the operational areas that matter most to an organization’s strategic goals. It requires focused leadership, disciplined execution, and a culture of continuous improvement. By aligning initiatives with market needs and business strategies, organizations can create a sustainable advantage and drive long-term success.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.