Plan for Every Part (PFEP) is a structured methodology that plays a critical role in modern supply chain and inventory management systems. Originating from the principles of lean manufacturing, PFEP was first developed and refined by Toyota as part of the Toyota Production System (TPS).

The goal was clear: reduce waste, eliminate inefficiencies, and ensure that every component, no matter how minor, was accounted for in a highly organized and predictable way.

Table of contents

Historical Background of PFEP

The concept of PFEP emerged in the late 20th century, during a period when manufacturers were under increasing pressure to compete on quality, speed, and cost.

Traditional inventory management systems often fell short because they focused primarily on stock levels and reordering, neglecting vital information like part delivery schedules, packaging, handling instructions, and supplier performance. PFEP filled this gap by offering a more holistic and proactive approach.

At Toyota, PFEP became a cornerstone of their success in just-in-time (JIT) production. Instead of reacting to inventory needs, they meticulously planned every aspect of every part’s lifecycle—from sourcing and delivery to storage and usage on the production line. This level of planning drastically reduced production downtime, improved material flow, and ensured consistent product quality.

Over time, the benefits of PFEP began to gain recognition outside of Japan. As lean manufacturing principles spread globally, manufacturers in North America, Europe, and beyond adopted PFEP as a key strategy in optimizing their supply chain operations. Today, companies of all sizes—from large automotive firms to small electronics manufacturers—leverage PFEP to drive efficiency, reduce operational costs, and enhance supply chain visibility.

In this article, we’ll explore how to implement a PFEP strategy in your organization, the benefits it brings, common challenges you may face, and best practices to ensure long-term success.

Public, Onsite, Virtual, and Online Six Sigma Certification Training!

- We are accredited by the IASSC.

- Live Public Training at 52 Sites.

- Live Virtual Training.

- Onsite Training (at your organization).

- Interactive Online (self-paced) training,

What Is “Plan for Every Part”?

“Plan for Every Part” is a systematic approach to managing materials in manufacturing and logistics. It involves creating detailed plans for each part or component used in the production process. This includes specifying storage locations, order quantities, delivery schedules, and handling procedures.

By having a clear plan for every part, businesses can ensure that materials are available when needed, reducing delays and minimizing excess inventory.

Understanding PFEP

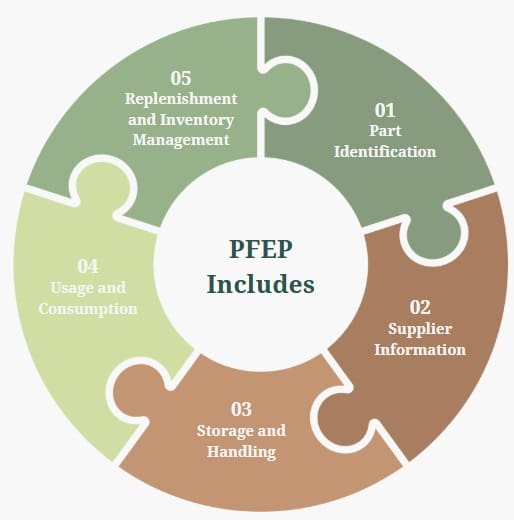

At its essence, PFEP is a comprehensive plan that details every aspect of each part used in the manufacturing process. This includes:

- Part Identification: Unique identifiers such as part numbers and descriptions.

- Supplier Information: Details about the part’s supplier, including lead times and delivery schedules.

- Storage and Handling: Specifications on how and where the part is stored, its packaging, and handling requirements.

- Usage and Consumption: Data on how often the part is used, its consumption rate, and its criticality to production.

- Replenishment and Inventory Management: Guidelines on reorder points, safety stock levels, and inventory turnover.

By systematically addressing these elements, PFEP ensures that every part is readily available when needed, minimizing production delays and optimizing inventory levels.

Also Read: What is an Out of Control Plan?

Importance of PFEP in Modern Manufacturing

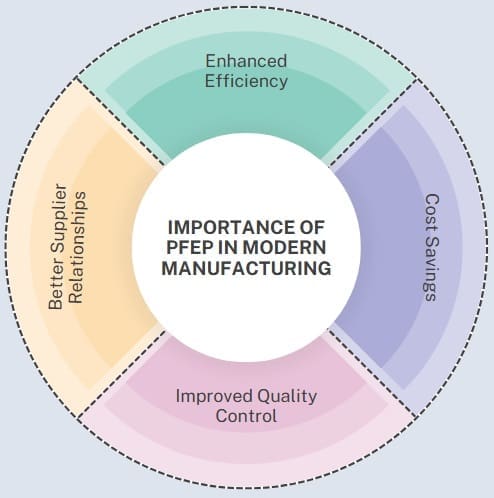

Implementing a PFEP strategy offers several advantages:

- Enhanced Efficiency: With detailed plans in place, operations run more smoothly, reducing downtime and bottlenecks.

- Cost Savings: Optimized inventory levels mean less capital tied up in excess stock and reduced storage costs.

- Improved Quality Control: Clear handling and storage instructions help maintain the integrity of materials, leading to higher-quality products.

- Better Supplier Relationships: Transparent planning fosters trust and collaboration with suppliers, ensuring timely deliveries and consistent quality.

Key Components of a PFEP

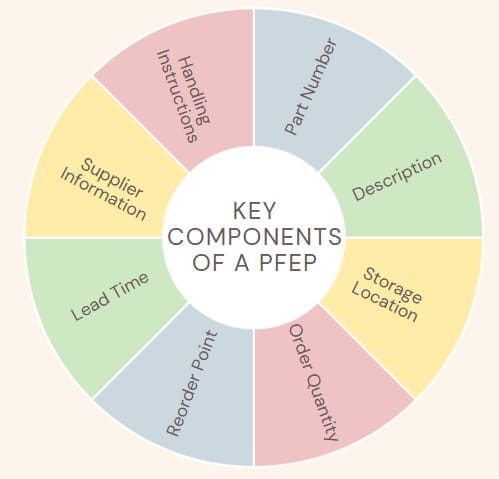

A comprehensive PFEP includes:

- Part Number: Unique identifier for each component.

- Description: Detailed information about the part.

- Storage Location: Where the part is kept within the facility.

- Order Quantity: The amount typically ordered.

- Reorder Point: Inventory level at which new orders should be placed.

- Lead Time: Time taken from ordering to receiving the part.

- Supplier Information: Details of the part’s supplier.

- Handling Instructions: Guidelines for storing and moving the part.

Also Read: What is Project Planning?

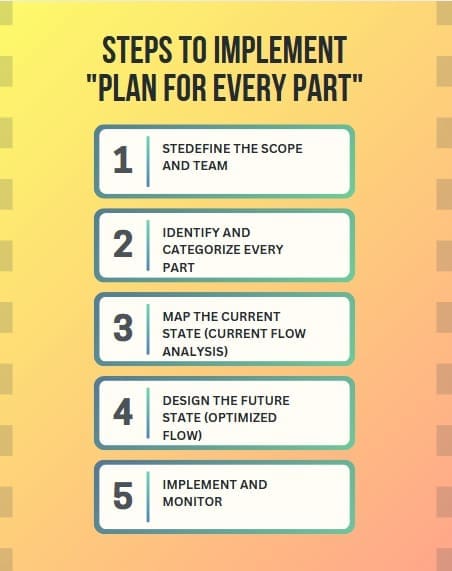

Steps to implement “Plan for Every Part”

Implementing a PFEP is a significant undertaking, but its long-term benefits far outweigh the initial effort. Here’s a structured approach to building your own:

Step 1: Define the Scope and Team

Start by clearly defining which parts will be included in your PFEP. Will you focus on a specific product line, a critical manufacturing process, or your entire inventory? Assemble a cross-functional team comprising representatives from:

- Procurement/Purchasing: Understanding supplier relationships and lead times.

- Manufacturing/Production: Insights into consumption rates and assembly processes.

- Logistics/Warehousing: Expertise in material handling, storage, and transportation.

- Sales/Demand Planning: Providing accurate demand forecasts.

- IT/Data Management: For data collection, analysis, and system integration.

This collaborative approach ensures buy-in and incorporates diverse perspectives.

Step 2: Identify and Categorize Every Part

This is the foundational data collection phase. For every part within your scope, gather comprehensive information. This includes:

- Part Number and Description: Unique identifiers and clear descriptions.

- Supplier Information: Primary and secondary suppliers, contact details.

- Current Stock Levels and Locations: Where is the part currently stored?

- Annual Usage/Demand: Historical consumption data and forecasted demand.

- Lead Time: From order placement to receipt.

- Cost Information: Unit cost, freight costs, import duties.

- Physical Characteristics: Dimensions (length, width, height), weight, special handling requirements (e.g., fragile, temperature-sensitive, hazardous).

- Packaging Details: Standard package quantity, container type (e.g., pallet, carton, tote).

- Quality Requirements: Any specific certifications or inspection needs.

- Safety Stock Levels: Minimum inventory to buffer against uncertainty.

- Reorder Point and Quantity: When to order and how much.

Consider categorizing parts based on criticality (e.g., A, B, C classification based on value or impact on production), usage patterns, or supplier relationships.

Step 3: Map the Current State (Current Flow Analysis)

Before you optimize, you must understand your existing processes. Document the current flow of each part from supplier to point of use. This involves:

- Receiving Procedures: How are parts currently received and inspected?

- Storage Locations and Methods: Where are they stored, and how are they organized?

- Internal Transportation Routes: How do parts move within your facility?

- Delivery Frequency to Point of Use: How often are parts delivered to the production line?

- Material Handling Equipment Used: Forklifts, hand trucks, conveyors.

Value Stream Mapping (VSM) can be an excellent tool for this step, visually representing the current flow and identifying areas of waste.

Step 4: Design the Future State (Optimized Flow)

Based on your data and current state analysis, design the ideal future state for each part. This involves making strategic decisions about:

- Optimized Inventory Levels: Determine ideal safety stock, reorder points, and order quantities to minimize holding costs while ensuring availability.

- Delivery Frequency and Batch Sizes: Can you move to more frequent, smaller deliveries (e.g., milk runs) to reduce inventory at the point of use?

- Packaging and Containerization: Are current containers efficient for storage and transport? Can you standardize to reusable containers?

- Internal Logistics and Layout: Are your internal routes efficient? Can you re-layout storage or production areas to reduce travel time?

- Supplier Collaboration: Can you work with suppliers to reduce lead times, improve delivery reliability, or implement vendor-managed inventory (VMI)?

- Technology Integration: How can technology (e.g., WMS, ERP, automation) support the optimized flow?

This step requires creativity and a willingness to challenge existing norms.

Step 5: Implement and Monitor

Once you’ve designed your future state, begin implementing the changes systematically. This is an iterative process, so start with a pilot project or a specific product line to test your assumptions and refine your plan. Key aspects of implementation include:

- Training: Ensure your team understands the new processes and their roles.

- System Updates: Integrate PFEP data into your ERP, WMS, or other relevant systems.

- Physical Changes: Reconfigure storage areas, implement new signage, or acquire new equipment.

- Supplier Engagement: Communicate new requirements and collaborate on transition plans.

Crucially, establish key performance indicators (KPIs) to continuously monitor the effectiveness of your PFEP. These might include:

- Inventory Turns: How quickly is your inventory moving?

- Days of Inventory on Hand (DIOH): How many days of sales can your current inventory cover?

- Storage Costs per Unit: The cost of storing each item.

- On-Time Delivery Rate: How often are parts delivered as scheduled?

- Production Downtime due to Part Shortages: A critical measure of impact.

- Expedited Shipping Costs: Indicative of inefficiencies.

Regularly review these KPIs and use the insights to continuously improve your PFEP. This isn’t a one-time project; it’s an ongoing journey of optimization.

Challenges in PFEP Implementation

While PFEP offers numerous advantages, businesses may encounter challenges such as:

- Data Accuracy: Inaccurate or outdated information can lead to planning errors.

- Resistance to Change: Employees accustomed to existing processes may be hesitant to adopt new methods.

- Resource Constraints: Implementing PFEP requires time and effort, which may strain resources.

Overcoming these challenges involves clear communication, training, and a phased implementation approach.

Also Read: What is Scenario Planning?

Best Practices for PFEP Success

To maximize the benefits of PFEP:

- Regular Updates: Continuously update the PFEP to reflect changes in parts, suppliers, and processes.

- Employee Training: Ensure all staff are trained on PFEP principles and procedures.

- Continuous Improvement: Regularly review and refine the PFEP to enhance efficiency and effectiveness.

Also See: FMEA Template

Final Words

Adopting a “Plan for Every Part” strategy is a proactive approach to managing materials in manufacturing and logistics. By meticulously planning for each component, businesses can achieve greater efficiency, cost savings, and product quality. While challenges may arise, the benefits of PFEP make it a worthwhile endeavor for organizations aiming to streamline their operations.

FAQs

Q1: How does PFEP differ from traditional inventory management?

PFEP goes beyond basic inventory management by creating detailed plans for each part, considering factors like storage, ordering, and handling. This comprehensive approach leads to more efficient operations.

Q2: Can small businesses benefit from PFEP?

Absolutely. While PFEP is often associated with large enterprises, small businesses can also reap its benefits by improving efficiency and reducing costs.

Q3: Is PFEP a one-time implementation or an ongoing process?

PFEP is an ongoing process. Regular updates and reviews are essential to adapt to changes in parts, suppliers, and production processes.

Q4: What tools are available to assist with PFEP implementation?

Various software solutions can assist with PFEP, offering features like data management, planning tools, and integration with existing systems.

Q5: How can I overcome resistance to PFEP within my organization?

Overcoming resistance involves clear communication, demonstrating the benefits of PFEP, and providing training to ensure all employees are on board with the new approach.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.