Factory layout involves allocating space for equipment, workers, materials and supporting activities to optimize economical production, effective service design and a safe working environment. It encompasses the physical arrangement of departments, machinery, equipment and services within an organization to facilitate efficient product creation or service provision.

Table of contents

- What is Factory Layout?

- 6 Basic Principles of Factory Layout

- Factory Layout Options

- Factors Affecting Factory Layout

- Difference Between Process and Product Layout

- Single-Storey vs. Multi-Storey Factory Layout

- Key Elements of Layout Planning

- Factory Layout Procedure

- Benefits of an Efficient Factory Layout

- Final Words

- Related Articles

What is Factory Layout?

A factory layout refers to the strategic arrangement of physical facilities to achieve the fastest and most cost-effective workflow with minimum handling, from receiving raw materials through the production of finished products and dispatch. It aims to allocate resources effectively while simultaneously minimizing operational expenses while assuring efficient operations.

Public, Onsite, Virtual, and Online Six Sigma Certification Training!

- We are accredited by the IASSC.

- Live Public Training at 52 Sites.

- Live Virtual Training.

- Onsite Training (at your organization).

- Interactive Online (self-paced) training,

Characteristics of an Effective Factory Layout

An ideal plant layout must:

- Leverage Space Efficiently: Make full use of available space without congestion.

- Be Accessible: Ensure sufficient room for material handlers and product transportation.

- Plan for Future Growth: Design with potential future expansion in mind to avoid restrictions.

- Tailor the Layout to Operational Needs: Tailor your layout according to the unique requirements of your business.

Also Read: What is Visual Factory?

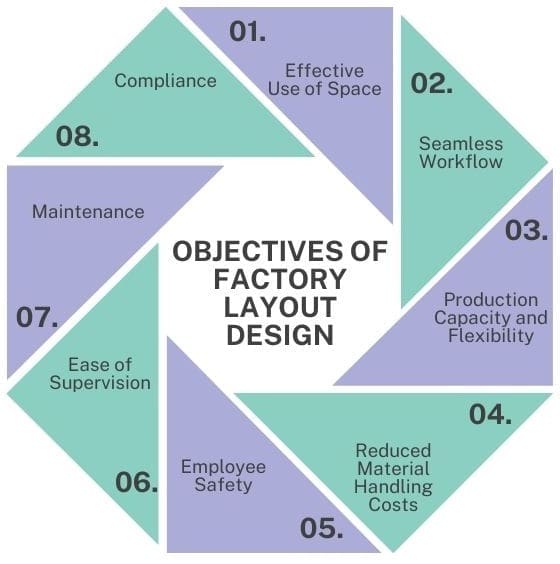

Objectives of Factory Layout Design

An effective factory layout must achieve several objectives.

- Effective Use of Space: Utilizing all available floor space efficiently to avoid congestion and ensure smooth workflow.

- Seamless Workflow: Assure that work transitions from one step to the next without incurring unnecessary delays.

- Production Capacity and Flexibility: Establish sufficient production capacity with room for expansion.

- Reduced Material Handling Costs: Minimize costs associated with moving materials within the factory, such as material handling costs.

- Employee Safety: Provide employees with safe workplace environments by minimizing accidents and injuries, maximizing labour and equipment productivity and controlling waste effectively while efficiently storing inventory.

- Ease of Supervision: Simplify the supervision and control of production processes.

- Maintenance: Facilitate easy maintenance of plant and equipment

- Compliance: Adhere to local regulations and standards.

6 Basic Principles of Factory Layout

Factory layout design should follow several fundamental principles to ensure maximum performance and efficiency:

- Integration Principle: Integrating men, materials and machines for maximum operational efficiency.

- Flow Principle: Facilitating an uninterrupted, smooth flow of materials and resources throughout a system.

- Space Utilization Principle: Making optimal use of available space in order to minimize waste and inefficiency.

- Minimum Movement Principle: Limiting unneeded movement of both people and materials in order to save both time and costs.

- Safety and Comfort Principle: It is concerned with prioritizing worker safety and comfort to improve productivity and morale.

- Flexibility Principle: Producing layouts that facilitate simple adaptation to ever-evolving production requirements.

Also Read: What is Cellular Manufacturing?

Factory Layout Options

| Layout Type | Description | Advantages | Disadvantages | Suitable For | Example |

| Product (Line) Layout | Equipment is arranged in a sequence according to the production process. | Low cost, smooth operations, and simple production control. | Lacks flexibility; a breakdown in one process can halt entire production. | Mass production with repetitive processes and stable demand. | Assembly lines for automobiles or electronics. |

| Process Layout | Similar processes are grouped together. | Highly flexible, adapts to changes in volume/product variety, and specialized supervision. | Requires skilled labor, and strong production controls to prevent delays and inventory accumulation. | Non-standard products, smaller quantities, frequent design changes. | Custom furniture manufacturing, small-batch production facilities. |

| Combined Layout | A blend of product and process layouts, with some steps following product layout and others following process layout. | Offers efficiency and better production controls. | Complex to design; small errors can create bottlenecks. | Large manufacturing organizations for FMCG. | Large-scale FMCG factories with diverse product lines. |

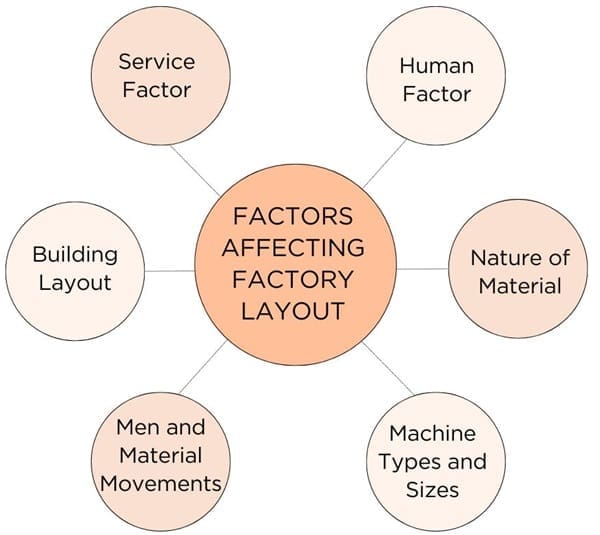

Factors Affecting Factory Layout

Factory layout design can be affected by numerous variables ranging from the production process itself to human resource considerations:

- Human Factor: Worker capabilities, preferences and capabilities play a crucial part in the design of any layout.

- Nature of Material: Raw materials, WIP or finished goods all impact decisions regarding layout design decisions.

- Machine Types and Sizes: When selecting and placing machinery in a production environment, selection depends upon production requirements and technological considerations.

- Men and Material Movements: For successful operations to take place smoothly, efficient material flow as well as worker mobility must occur simultaneously.

- Building Layout and Infrastructure: The physical layout and infrastructure of a building has an effect on its overall layout design.

- Service Factor: To optimize design efficiency, support services like maintenance, quality control, employee facilities must also be integrated into its layout design.

Difference Between Process and Product Layout

| Characteristic | Process Layout | Product Layout |

| Nature | Facilities grouped by function. | Facilities are arranged in a sequence of operations. |

| Application | Ideal for job order production with diverse products. | Suited for mass production of standardized items. |

| Equipment | General-purpose machines; versatile employment. | Specialized machines; specific to product type. |

| Material Handling | Variable; loads and paths adapted to job needs. | Fixed; mechanized or automated handling systems. |

| Resource Utilization | High utilization rates; localized disruptions. | Lower utilization rates; specific to product line. |

| Inventory Requirements | High in-process inventories; job-specific setups. | Reduced in-process inventories; continuous flow. |

| Floor Area | More floor space is required for the layout. | Compact layout; less floor space needed. |

| Production Control | Complex; individual handling of job orders. | Simplified; integrated into the production line. |

| Flexibility | High; can accommodate diverse product variations. | Low; suited for consistent product specifications. |

| Maintenance | Easy; general-purpose machines. | Maintenance can disrupt the entire production line. |

| Production Planning | Complex; individualized planning for each order. | Simplified; planning integrated into line design. |

| Production Time | Longer setup and processing times. | Shorter setup and processing times. |

| Worker Morale | High; workers have varied tasks and autonomy. | Lower; repetitive tasks may lead to monotony. |

Also Read: What is Lurking Variable?

Single-Storey vs. Multi-Storey Factory Layout

Choosing between a single-storey and a multi-storey building depends on several factors, including land availability, cost, and production needs.

| Aspect | Single-Storey Layout | Multi-Storey Layout |

| Floor Load Capacity | Greater floor load capacity, no need for upper strength support. | Lower floor load capacity, requires structural strength for multiple floors. |

| Noise and Vibration | Lower noise transmission and building vibration. | Higher noise transmission and vibration potential due to multiple floors. |

| Construction Costs | Easier and lower cost of construction and expansion. | Higher construction costs due to structural requirements for multiple floors. |

| Natural Light/Ventilation | Lower floor load capacity requires structural strength for multiple floors. | Limited natural light and ventilation, especially on lower floors. |

| Floor Area Usability | More floor area usable for processing, no need for stairwells or lifts. | Less usable floor area due to space occupied by stairwells, lifts, etc. |

| Service Facilities | Centralized service facilities reduce operating costs. | Costlier decentralized service facilities due to multiple floors. |

| Material Handling | More efficient material handling and product routing. | Material movement between floors increases complexity and costs. |

| Supervision Costs | Lower supervision costs due to centralized layout. | Higher supervision costs due to multiple floors and dispersed operations. |

Also See: What is a Black Belt in Six Sigma?

Key Elements of Layout Planning

Layout planning entails visualizing an optimal arrangement for equipment and machinery to minimize internal transport and costs, taking careful note of:

- Material Flow: Efficient movement of materials that reduces handling costs

- Space Utilization: Equipment should be placed to make maximum use of available space while remaining flexible enough for future expansion and changes to production processes.

- Flexibility: Designs that accommodate future expansion/changes must allow for future adjustments that occur over time.

Factory Layout Procedure

The design process for factory layout involves taking a systematic approach to gathering data, evaluating requirements, and creating a plant layout that meets an organization’s needs.

- Information Collection: Accumulating information such as production volume, process requirements and resource utilization to form the basis of an information-gathering initiative.

- Analysis and Coordination: Examining data to ascertain workforce size, equipment needs and space requirements.

- Choice of Machinery and Equipment: Selecting appropriate machinery based on production needs and technological considerations.

- Selecting Material Handling Systems: Selecting material handling systems according to movement requirements and safety considerations.

- Sketching Out The Factory Layout On A Plot: Outlining the plant layout on available plot space while taking into account natural factors like sunlight and ventilation.

- General Flow Pattern: Establishing the flow pattern of materials and resources through the plant to reduce bottlenecks and congestion.

- Individual Workstation Design: Generating optimal workstation designs in terms of performance, safety, and comfort.

- Assembly of Work Station Layout: Integrating individual workstations into the overall plant layout to facilitate efficient workflow.

- Storage Space Planning: Determining storage requirements based on inventory needs and material handling considerations.

- Generating Flow Diagrams: Assigning workstations according to process flowcharts.

- Designing and Locating Service Areas: Establishing offices, restrooms and cafeterias to support worker needs.

- Producing Master Layout: Constructing a master layout using templates and models to visualize the final design.

- Reviewing Final Layout: Conducting rigorous evaluation and testing procedures on the final layout to ensure it fulfils safety, economic, and operational criteria.

- Layout Approval: Before finalizing the layout design, official approval from relevant authorities must first be secured.

Benefits of an Efficient Factory Layout

Reduce Cycle Times Due to an Optimized Workflow: Increased production processes can be completed faster with proper factory layout design.

- Increased Operational Speed: Simplified operations with reduced travel distance for materials and personnel.

- Maximized Space Utilization: Efficient use of space to lower land and operating costs.

- Improved Process Visualization: Ability to modify and optimize processes through visualization.

- Increased Profits: Efficiency gains translate to increased profitability.

Final Words

Factory layout design is a complex task that must take careful consideration of multiple factors to maximize efficiency, safety and cost-effectiveness. By adhering to established principles and procedures, organizations can develop layouts that promote productivity while streamlining operations and offering employees a productive work environment.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.