Table of contents

- Lean Six Sigma in Construction

- A View of the Construction Industry and Its Challenges

- What does Six Sigma mean in construction management?

- There are differences between traditional construction and lean construction Lean Construction

- Customer’s perception of value

- Principles of Lean Six Sigma in Construction

- Related articles

Lean Six Sigma in Construction

The Lean Six Sigma method in Construction applies principles of lean thinking and adapts the methodology training to each sector, like manufacturing. It aims to lower costs, minimize damage to buildings, and speed up the delivery process to ensure everything arrives on time.

Lean Construction is different from Lean Manufacturing training in that the workplaces change for every enterprise and the workers move around the product. There is also almost no repetition in enterprises.

A View of the Construction Industry and Its Challenges

Construction is the lean manufacturing training industry. It involves building, maintaining and repairing structures like roads, bridges and buildings. This broad field includes many trades and specialties such as electrical work, plumbing and carpentry. This industry contributes significantly to the country’s economy and employs many people.

You can fund construction projects from small renovations to multi-billion-dollar developments. To ensure safety and quality, the industry is subject to numerous regulations and building codes.

What does Six Sigma mean in construction management?

- 1. Don’t look at the problem from your perspective. It is important to speak in the language of your customers, and to point out specific goals.

- 2. You can measure key aspects of the process by gathering relevant data.

- 3. Analyze the data and search for cause-and effect relationships.

- 4. Six Sigma can help you improve your current process. Six Sigma will suggest data analysis techniques to use the information and reconfigure the process. To determine if the improvement is genuine, you can set up tests.

- 5. Once you have implemented the improvement, you can control the process.

There are differences between traditional construction and lean construction Lean Construction

Conceptually, the main difference between traditional and lean construction methods is conceptual. It is the way you view the production process.

In the traditional method we only look at the process and divide it into subprocesses. Lean, however, separates activities that add value from those which don’t.

It doesn’t add value if the customer won’t pay for it. Products that do not include movement, material flow or wait and rework are not valuable.

Lean thinking is a way to reduce waste and it is used often in project management.

Taiichi Ohno (head of the TPS) defined seven types, but later publications identified eight. These are:

Customer’s perception of value

We have seen that the basis of lean production is customer perceptions of value. To be considered a value-adding activity, it must fulfill certain criteria, including:

- The client must pay for the activity.

- The activity should in some way transform the product/service

- You must complete the activity correctly the first time.

The customer’s value is the sum of all the benefits and the cost. The customer perceives the customer’s value as higher than the cost.

A satisfied customer is one that is pleased with the company’s performance.

If the company is able to deliver a performance that exceeds the expectations of the customer, the customer will be a loyal soldier of the company. This customer will also become an advertisement channel for the company.

Principles of Lean Six Sigma in Construction

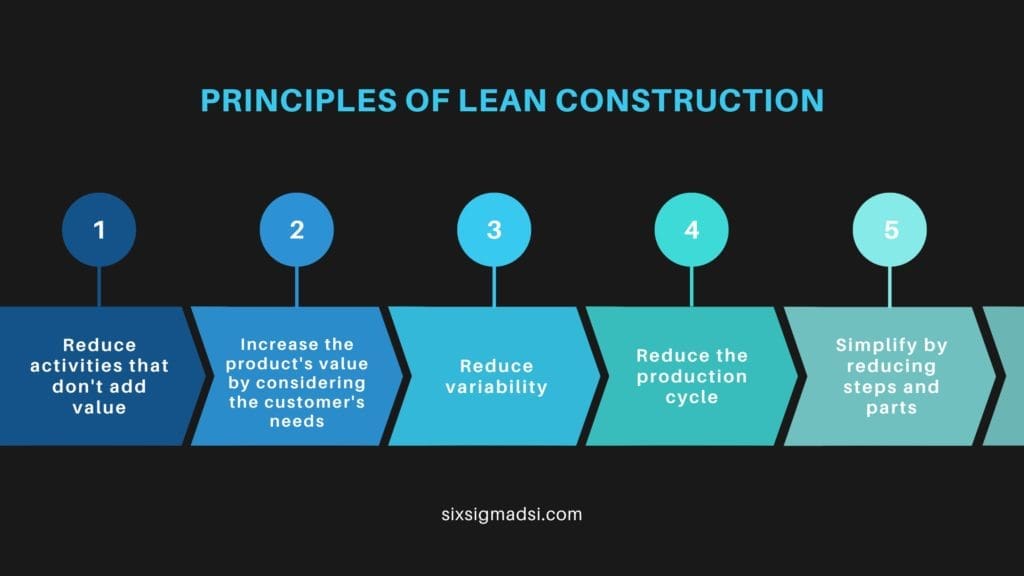

Let’s focus on the most significant and important 5:

1: Reduce activities that don’t add value

This is a fundamental principle of lean construction method. This principle can help improve the process efficiency and reduce its losses. It is possible to do this by improving the efficiency and conversion of activities.

flow but also by eliminating certain flow activities.

We must not take this principle too far. As we’ve seen, there are some activities that are not of any value, but essential to overall efficiency. These include dimensional control, training the workforce, and the installation of safety devices.

The first step to reducing these activities is to make the flow activities explicit by displaying the process flow. These activities can then be controlled and, where possible, eliminated.

2: Increase the product’s value by considering the customer’s needs

This principle is closely related to the idea of process as a value-generating agent. This principle demonstrates that customers both internal and externe must be identified. This information should be taken into account in product design as well as production management.

This principle can be applied by process mapping. It involves systematically identifying customers as well as their needs for each stage.

This principle can only be applied efficiently if we remember that the customer is not just the external customer who ordered the enterprise but also the work team which was the internal customer.

3: Reduce variability

Variability can come in three forms:

- Variability in past processes: It is related to suppliers. Ex: Large dimensional variations in ceramic blocks.

- Variability in the execution of the process: This is the variability that occurs during the execution. Ex: Variability in execution time of an activity over multiple cycles.

- Variability in Demand: This refers to the needs and desires of clients during a process. Example: Some customers of a developer request changes to the building design.

Why reduce variability? A uniform product is more satisfying for the customer because it matches the specifications.

This principle is not to be ignored. We will have problems with our production. Our activities that don’t add value will increase and we will need more time to produce a product.

- Interference between teams can cause disruptions in workflows. This occurs when a team is unable to move to another work area or stands still due to delays from the previous team.

- Rework or rejections may result from the customer refusing to accept products that are not specified.

4: Reduce the production cycle

This principle is a result of the Just in Time philosophy that was created by TPS. The sum of all the times it takes (transport, waiting, processing, inspection) to make a product can be called cycle time.

This principle is closely related to the necessity to compress time as a means to eliminate flow activities.

This feature can be applied to a wide range of actions, including:

- Elimination of flow activities which are part of the production process.

- Production planning and control can help you concentrate your production effort on fewer units (or smaller batches).

- Modifications in the precedence relationships between activities, eliminating interdependencies among them, so they can be executed simultaneously.

5: Simplify by reducing steps and parts

This principle is used often in the design of simplified building systems. This principle is often used to develop streamlined building systems. The more steps or components in a process, then the less value-add activities.

This is due in part to the additional preparation and completion tasks needed for each step of the process (eg cleaning, scaffolding, final inspection etc.). It is also due to the fact that there is more chance of inter-team conflict in the face of variability.

We can simplify things by using some techniques such as:

- Prefabricated elements reduce the steps required to build a building component.

- Multipurpose teams are preferred to specialized ones.

- Planning effectively for the production process is essential to avoid interdependencies and combine small tasks into larger ones.

Six Sigma and lean are key to achieving high customer satisfaction. They provide structured methods for improvement that reduce waste, speed up production, and lower lead times.

Lean and six sigma are best practiced beyond production. The concepts must be used for everything from land development to marketing, sales, estimation, design, purchase, construction, warranty, service, finance, administration, and even marketing.

Have you worked on a Six Sigma project for Construction?

Tell us your experience in the comments below.