Table of contents

Lean Manufacturing Practices: What Are They?

Lean manufacturing practices are a method that minimizes waste in manufacturing processes while increasing productivity. Anything that customers don’t believe adds value or is not worth paying for is considered waste. Lean manufacturing concepts and principles have many benefits, including reduced lead times and lower operating costs as well as improved product quality which is why companies that use lean manufacturing see great benefits.

More than ever, speed to market, operational efficiency, and flexibility are key factors in manufacturing’s volatile, fast-paced environment. Lean manufacturing is being adopted by companies to gain a competitive edge.

Lean manufacturing, also known as lean production or lean, can be enabled by organizations in many fields. Toyota, Intel, and John Deere are just a few of the well-known companies that use lean manufacturing. This approach was developed from the Toyota Production System. It is still being used by many other companies, including Nike and John Deere. Enterprise resource planning ( ERP), can also benefit by using a lean production method.

Lean manufacturing is founded on several principles such as Kaizen or continuous improvement.

Lean manufacturing was first introduced to the West by the 1990 publication The Machine That Changed the World. This was based upon an MIT study on the future of the automobile, and detailed Toyota’s lean production process. Lean principles have influenced many industries, not only manufacturing but also software development and healthcare.

Types of Waste in Lean Six Sigma

- Transportation: Unnecessary movement of materials or information between locations can lead to delays and errors. Lean manufacturing focuses on streamlining transportation to minimize waste in companies.

- Inventory: Excessive inventory ties up valuable resources, occupies space, and can lead to waste due to obsolescence or damage. Lean manufacturing aims to optimize inventory levels to reduce waste.

- Motion: Wasteful movements of people or equipment within a workspace can lead to inefficiency and errors. Identifying and eliminating unnecessary motion is crucial in Lean Six Sigma projects.

- Waiting: Delays in processes due to waiting for materials, information, or approvals can lead to lost time and reduced productivity. Lean Six Sigma focuses on reducing waiting time to enhance efficiency.

- Overproduction: Producing more than what is required by the customer leads to excess inventory and waste of resources. Lean Six Sigma emphasizes producing items in the right quantities at the right time to prevent overproduction.

- Overprocessing: Performing unnecessary or redundant steps in a process can consume valuable resources without adding value. Lean Six Sigma projects aim to eliminate overprocessing and streamline processes.

- Defects: Defective products or services require rework, leading to additional time, effort, and resources. Lean Six Sigma tools are used to identify the root causes of defects and implement solutions to prevent them.

- Underutilized Talent: Not tapping into the skills and expertise of employees is a waste of valuable resources. Lean Six Sigma encourages organizations to engage and empower their employees, utilizing their talents effectively.

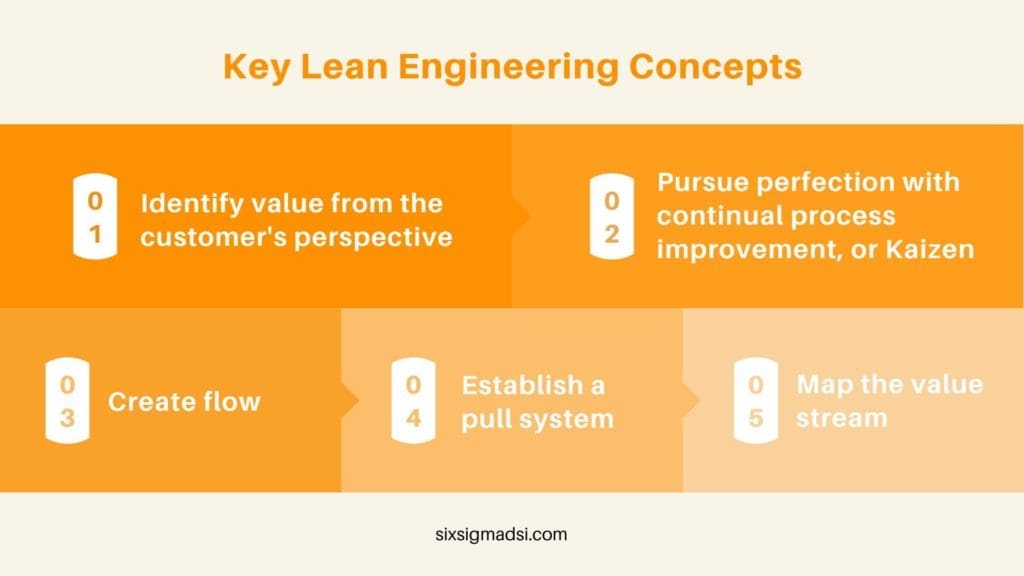

5 Principles of Lean Manufacturing

Lean Thinking: Banish Waste and Create Wealth for Your Corporation is a widely-referenced book that laid out five principles to lean. It was published in 1996. Many in the field refer to it as the core principles. They are the value stream (value stream), flow (pull), and perfection. These are used now as the foundation for lean implementation.

1. Value is best understood from the perspective of the customer. The producer creates value, but the customer defines it. Understanding the customer’s value can help companies determine the amount of money they are willing to spend on their products or services.

To achieve the best price for the customer, the company must eliminate all waste and costs from its business processes. This will allow the company to make the most of its profits.

2. The value stream can be mapped. This principle involves recording and analyzing the flow of information and materials necessary to create a product or service. The goal is to identify waste and improve the process. Value stream mapping covers the entire product’s lifecycle, including raw materials and disposal.

Each stage must be inspected by companies to identify waste. Any waste that doesn’t add value should be eliminated. Lean thinking suggests that supply chain alignment is part of this effort.

3. Facilitate flow. Reduce functional barriers and find ways to increase lead time. This helps to ensure smooth processes from order receipt through delivery. The elimination of waste is dependent on flow. Lean manufacturing is about avoiding interruptions in production and creating a unified and integrated set that allows activities to move in a continuous stream.

4. Set up a pull system. This allows you to only take on new work when it is needed. Lean manufacturing employs a pull system rather than a push system.

In manufacturing resource planning (MRP), push systems are used. A push system allows for inventory to be planned in advance and product manufacturing can take place according to that forecast. Forecasts can be inaccurate and lead to swings in inventory levels, disrupted schedules, and poor customer service.

Lean manufacturing, which is different from MRP, is based on a pull system. This means that nothing is bought or manufactured until there is demand. The pull is based on flexibility and communication.

5. Kaizen is a way to strive for perfection through continuous process improvement. Lean manufacturing is based on the idea of continuously striving to achieve perfection. This involves identifying the root causes and eliminating waste from the value stream.

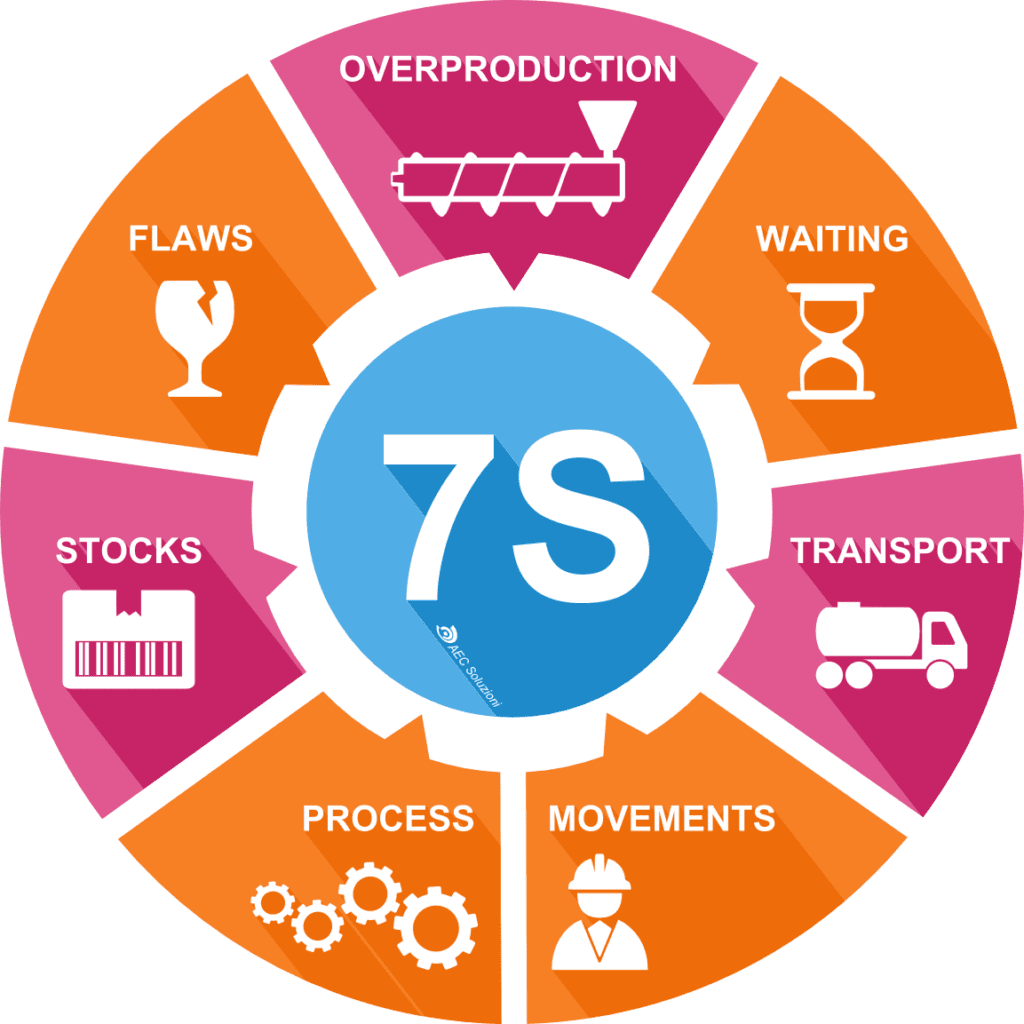

The 8 Wastes in Lean Production

The Toyota Production System identified seven “wastes” (processes and resources that aren’t adding value to the customer) These seven wastes include:

- Unnecessary transportation

- Stock surplus

- The unnecessary motion of equipment, people, or machinery

- Waiting, whether it’s people or equipment that is idle;

- Over-production of a product

- Over-processing is putting more effort into a product than the customer requires. This includes designs that are too complex or require expensive machinery to add unnecessary features.

- These defects can be costly and time-consuming to correct.

Many lean practitioners, even though it was not included in the original Toyota Production System, point out an eighth waste: the waste of talent and ingenuity.

7 Lean Manufacturing Concepts and Tools

Lean manufacturing demands that you constantly seek to reduce any product that doesn’t add value, which is waste. Continuous improvement is the core of lean manufacturing.

Lean also relies upon the following concepts and processes:

- Heijunka is a production leveling or smoothing process that aims to create a continuous flow in production, releasing work to plants at the appropriate rate and avoiding interruptions.

- 5S: A collection of methods for organizing workspaces to make them more efficient, productive, and safer for employees. Organization and cleanliness are the keys to 5S.

- Kanban is a signal that streamlines processes and creates just-in-time delivery. A signal can be either physical (e.g., a tag, empty bin) or electronic (e.g., sent through a computer system).

- Jidoka is a method for identifying abnormalities, stopping work until they can be corrected, and then solving the problem.

- Andon: A visual aid such as a flashing lamp that alerts workers when there is a problem.

- Poka-yoke: A mechanism to protect against human error. It may include an indicator light that lights up if you miss a step, a sign that indicates that a bolt has been tightened correctly, or a system that blocks your next step until you have completed all previous steps.

- The time it takes to make a part or complete an operation.

Six Sigma vs. Lean

Six Sigma is a method of data-driven management similar to lean. It aims to improve quality by identifying the defects in a process and eliminating them until they are eliminated.

Both Six Sigma and Lean are manufacturing concepts aimed at eliminating waste. Both Six Sigma and Lean have different methods because they deal with the root causes of waste differently.

Six Sigma focuses on process variation. Lean states that waste is created by extra steps and processes that customers don’t value. Six Sigma, however, says that it’s caused by customer-specific features. Both approaches can be combined to create a data-driven approach called Six Sigma.

Practicing Lean Manufacturing

Operational efficiency is key in the manufacturing industry. Lean manufacturing offers a method to minimize waste in manufacturing systems, which allows companies to achieve the operational efficiency that they need to stay ahead of their competition.

What practices do you use for your projects?

Let us know in the comments below.