Table of contents

- What is the definition of Kaizen?

- Definition of Kaizen Culture in Practice

- What will Kaizen give you?

- Definition of Kaizen Types

- How Kaizen Reduces the 7 Wastes of LEAN

- Definition of Kaizen Approach?

- Here are some suggestions to help you use kaizen in your team

- What are the benefits?

- In Summary

- Related SSDSI Articles

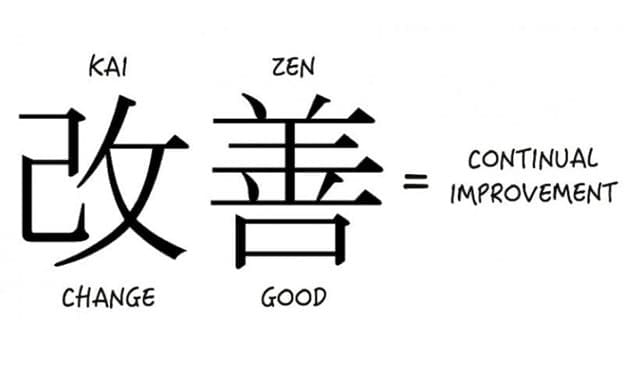

What is the definition of Kaizen?

The Shogakukan Dictionary’s original definition of Kaizen is translated as “The act or making bad points better”. In English, the more popular definition of Kaizen is “Change for Better”. Many believe that the Kaizen meaning is “continuous improvement” but, Kaizen is a result of continuous improvement. It exists at the employee’s level. The employee’s goal is to reach their potential, challenge the status quo and achieve continual improvement.

Kaizen means a way to make processes more efficient by improving existing processes and programs. Kaizen can be described as part “action plans” (in the form of Kaizen Events), and part “philosophy”.

Action Plans (or Kaizen Events) are a series of focus groups, teams, or events that focus on specific areas within an organization. All employees should be included in the Kaizen Event team and must focus on workers at the process level (we call them S.M.E. (or Subject Matter Experts)) The philosophy of Kaizen is about creating a culture in the workplace that encourages participation in suggesting and participating in improvements. This philosophy must be adopted at all levels of a company to create a sustainable LEAN (continuous improvement) environment.

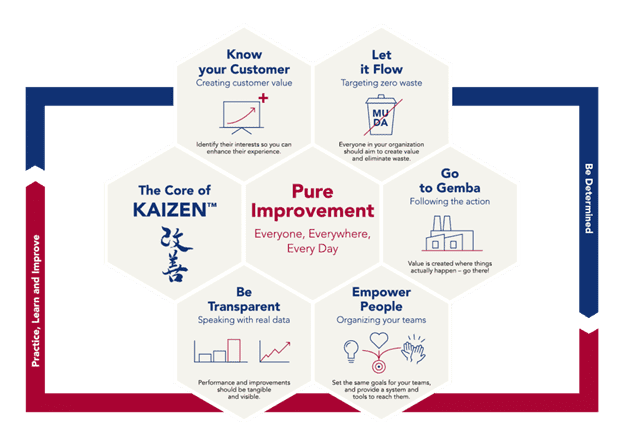

Definition of Kaizen Culture in Practice

To achieve Kaizen, the employee must practice self-criticism. This means they hold themselves accountable and look for ways to improve processes even when nothing is wrong. This mindset allows team members to challenge the status quo and push their limits. Positive thinking will make them feel successful, but it’s the negative emotion of “it could have been better” that will motivate them to improve performance and reach new heights.

In the Toyota production system, for example, every line employee is expected to stop any moving production line in the event of an abnormality. The staff and their supervisors will then suggest a solution.

A “reflection gathering” is held at the end of the Kaizen Event to review the whole process and any anomalies. It is important to note that the “reflection gathering” process could occur even if the project was completed successfully and there were no problems throughout its lifecycle.

These methods initiate Kaizen. They usually result in small improvements both during and after the process. The culture of continuous alignment and small improvements, as well as standardization, leads to significant productivity improvement changes.

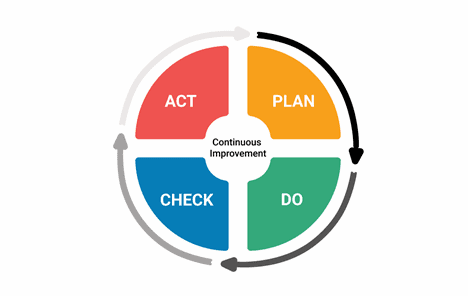

A further definition of Kaizen is a method of making changes, monitoring the results, and then adjusting. Smaller experiments can replace large-scale project planning and detailed scheduling. They can also be adjusted quickly if new improvements are made.

In LEAN, this cycle is used in a Kaizen Event called the PDCA (Plan, Do, Check, Act) Cycle:

- PLAN: Plan your improvements, including setting goals.

- DO: Take the necessary steps to improve your situation.

- CHECK: Measure your success relative to the baseline.

- ACT: Adjust or modify your changes.

You keep moving forward through each step. This represents continual improvement. You review your progress and plan for the next steps once you reach your baseline stage.

This is only the result of Kaizen. Continuous improvement is an external force. Definition of Kaizen, however, is the internal force that motivates you to continuously improve and challenge the status quo.

What will Kaizen give you?

Kaizen culture should be viewed as a way of living, a way to think. This will help you not only to improve your process but also improve yourself.

Knowledge sharing among team members and encouragement of each other’s development is a common good. This is the Kaizen cycle’s leadership style. Don’t be content with your own achievements, instead help others to reach theirs.

Definition of Kaizen Types

There are many ways that Kaizen can help your company. Some are quick and easy, while others require more strategic planning.

- System Kaizen: This is the opposite of point kaizen and is intended to solve system-level issues within an organization. This is a planned, organized, strategic-planning process that produces multiple planned kaizen events over a long period of time.

- Point kaizen: Point kaizen is an extremely popular way to implement the philosophy because of its simplicity and quick implementation. When someone spots a problem or an error in a process, they immediately address it and take corrective action. A supervisor might notice a defect in equipment or a delay in a process during a floor inspection. This is point kaizen. The supervisor might then ask the floor manager for quick Kaizen to fix the problem.

- Plane kaizen. Plane kaizen can also be referred to as value streams (several lines linked together) and is one level higher than line kaizen. A value stream is a way to organize traditional departments in an organization into product lines (value streams). This means that changes made in one line can be applied to other lines or processes.

- Cube Kaizen: Cube Kaizen is a situation in which all planes are connected to one another, leading to lean processes throughout the organization. Improvements can be made upstream and downstream, as well as throughout the organization, including suppliers, customers, and other stakeholders. Cube kaizen often requires the modification of standard business processes

- Line Kaizen: Line Kaizen is the use of lean techniques in both upstream and downstream departments or processes, creating a line between them. A short-term kaizen event could be executed in both the procurement and planning departments. Planning is directly affected by procurement.

How Kaizen Reduces the 7 Wastes of LEAN

Leaning using kaizen is about eliminating seven types of waste that can hinder efficiency. Let’s look at these types of waste so that you can identify what you need to look out for when you are looking for ways to improve your processes.

- Inventory: Unprocessed inventory includes storage waste, capital lost in unprocessed inventory, the waste of transporting the inventory, storage containers used to hold inventory and other expenses associated with the storage of inventory.

- Overproduction: Considered one of the most serious types of waste, overproduction can cause a domino effect, setting off many other types of waste and resulting in excess inventory. For example, having excess stock leads to multiple types of costs, including storage, wasted material, and excessive capital held up in inventory.

- Defects: Defects are any produced products that do not meet design standards or the customer’s expectations. Defective products are wasteful because they must be replaced. This requires more paperwork and labor. The company could also lose customers. Keep in mind that everything put into the defective product – from resources and material to labor – is wasted because the product won’t be used. Often, defects expose waste in other areas of the organization that may have led to the defect in the first place.

- Motion: The waste of motion refers to all motion – from humans or machines – that could be minimized. Wasted motion can be something as small as an employee searching for a tool to deal with machinery degradation.

- Transport: Moving material from one position to another is considered the waste of transport since the act of transporting itself doesn’t add value to the product. Minimizing transport might mean having the facilities involved in the production processes close to each other or finding ways to minimize transportation costs using more efficient methods. Transport leads to other types of waste, including resources and time used to handle material, employing staff or a third party to transport material, and having to train employees.

- Waiting: The waste of waiting is best described using the example of the assembly line. If one stop on the line takes longer than another, the employees in the next stop are waiting. Any time waste is caused by slowed or halted production in a previous area of the production chain, the waste of waiting occurs. In the case of kaizen, thinking of ways to improve the efficiency of the area causing the delay should be a priority.

- Overprocessing: Overprocessing refers to any part of the manufacturing process that isn’t necessary. For example, this would include adding features on a product that most likely won’t be used. In other words, you’re adding more value than the customer wants.

Definition of Kaizen Approach?

Kaizen is about continuous improvement. It’s not a one-off event. Instead, it’s a constant mindset that seeks to improve efficiency. This approach to continuous improvement can be broken down into six steps.

- Standardize: With a cross-functional team, think of ways to make straightforward, repeatable processes that will improve specific activities.

- Measure: Use quantifiable data to ensure that processes are efficient. How long does it take to complete a task with a new process as compared to an old one?

- Comparison: Compare your measurements and your requirements. Is the new process faster and more efficient?

- Innovate: Continue to search for better ways to do the same job and get the same result.

- Standardize (again): Once everyone is satisfied with a new idea or process that has been tested, make it reproducible and easy to follow by everyone.

- Continue: Restart the process.

This approach to Kaizen becomes second nature for the organization. Suggestions are a great way of driving kaizen, and the idea for continuous improvement. You should consider the suggestions of all members of your team and not just one person. The number of suggestions the team has submitted can help you measure the effectiveness of your suggestion scheme.

Here are some suggestions to help you use kaizen in your team

- A monthly brainstorming session is held to identify areas of waste in current processes. Use the idea log to help you go through the list of types of waste below and identify areas where improvements could be made.

- Keep a log for your team of the things that they see in their daily lives that are not working or efficient. It is easier to see things while you are doing them than if you sit in a room trying to remember them.

- Before implementing any changes, think about how they might impact other employees.

- Create a plan that will guide your team in how to implement the changes. You need to strike a balance between implementing the idea immediately and taking too long, which can lead to more waste.

What are the benefits?

Everybody Speaks the Same Language: Standardization and small continuous changes almost instantly bring everyone on the same page. Employees can be part of the process and help to improve themselves.

A Growth Mindset is a key to success: The most crucial components of a business’s success are its company values. Kaizen, a way to bring people together by having the same approach and mindset towards work and development is called Kaizen.

Motivation increases: When they feel that they are part in the improvement, team members are more motivated to participate and improve. They are more motivated to contribute when they see their ideas integrated with a continuous improvement process.

More acceptance of new ideas: Accepting the status quo can lead to a negative perception of new ideas and opportunities within your organization. Your teams will become more comfortable with and enjoy working with the idea of positive change if you have a continuous improvement strategy.

You will discover many other benefits. Kaizen, an integral part of Lean methodology, is essential when embarking on the journey to a Lean company. It minimizes waste.

In Summary

Kaizen can dramatically improve the efficiency and standardization of your company’s workflows, processes, and procedures. Kaizen can make a significant impact on employee engagement and culture, as well as workflow improvements. Kaizen is a way to transform the way your business works if everyone in it is committed to making positive changes at all levels of the company.