Table of contents

Estimated reading time: 7 minutes

What Is 5 Why Problem-Solving?

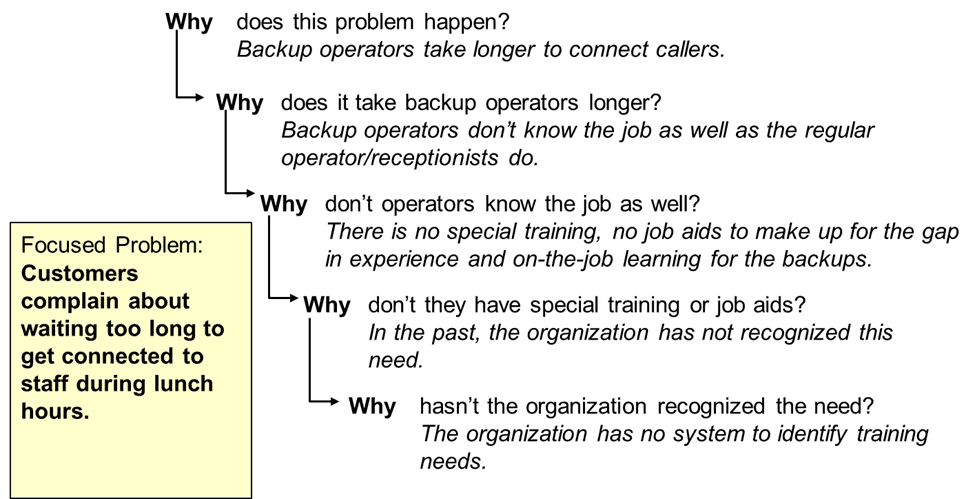

Although asking “Why?” might be the favorite strategy of your three-year-old child, it can also teach you valuable Lean Six Sigma lessons. The Analyze phase of the Lean Six Sigma DMAIC (Define Measure, Analyze and Improve, Control) methodology uses the 5 Whys diagram. This is a powerful Lean Six Sigma tool, which does not require data segmentation, hypothesis testing, or regression, and can often be done without the need for a data collection plan.

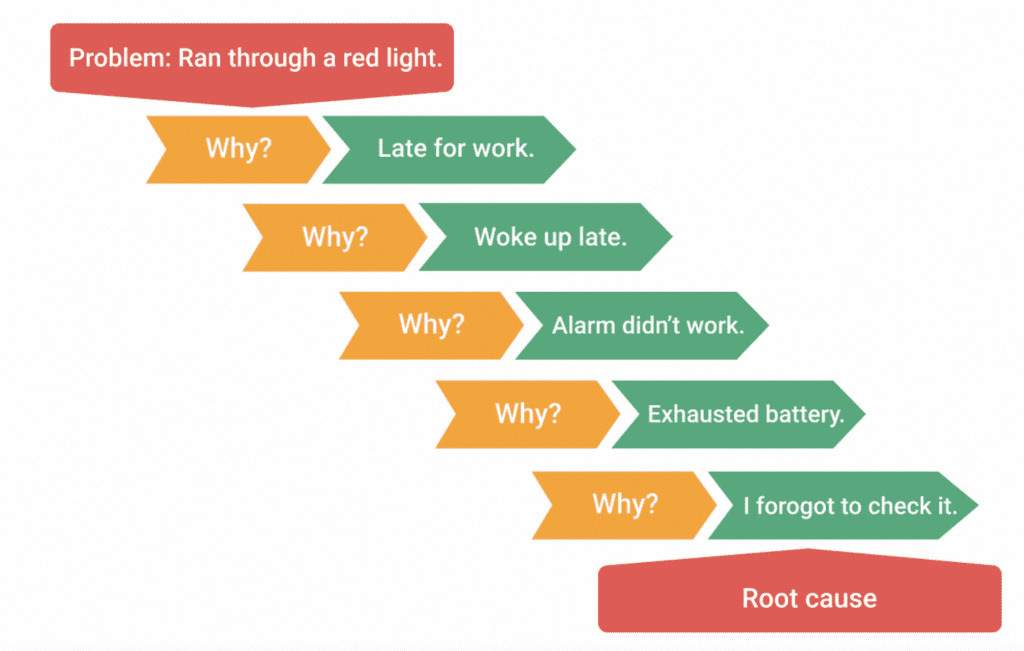

Asking the question “Why?” five times a day is a good way to uncover the cause of the problem. You will often find the root cause of a problem by asking another question. This diagram technique is known as “5 Whys” in Six Sigma, but you might find that you need to ask the question less than five times before you can find the problem.

Why the “5 Whys”?

The Five Whys in Six Sigma is a powerful non-statistical assessment method. It can trace problems to their root cause that weren’t obvious. The 5 Whys is a simple and effective tool.

The method “5 Whys” is named as such because it involves asking “why” repeatedly to delve deeper into the layers of a problem or issue to uncover its root cause. By asking “why” multiple times (typically five times), the method aims to encourage deeper investigation beyond the symptoms or immediate causes of a problem to identify the underlying root cause.

What are the Benefits of the 5 Whys?

- Understanding how one process can lead to a series of problems

- It helps to identify the root cause of a problem

- Highly effective without complex evaluation techniques

- Find out the relationship between root causes

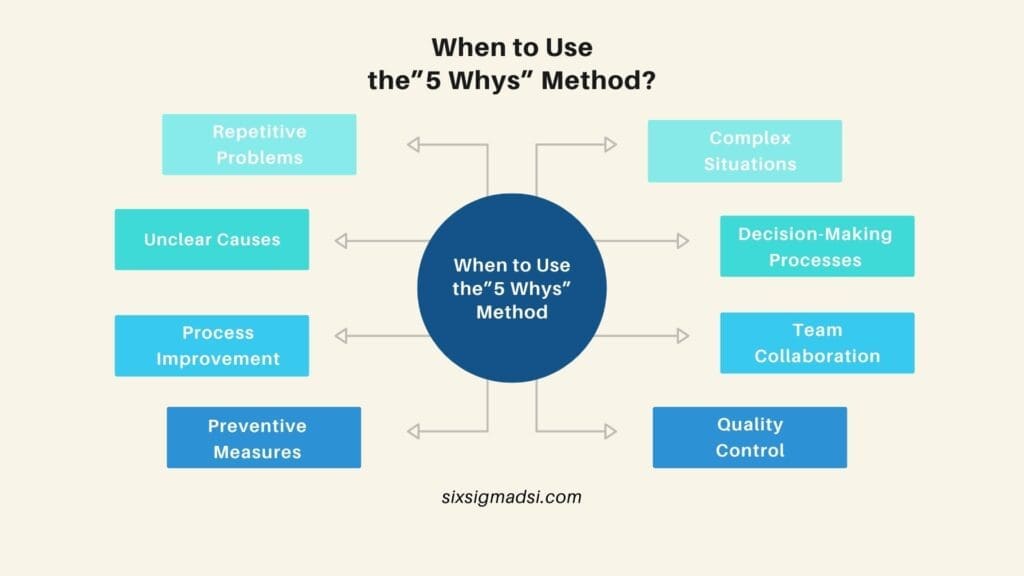

When to Use This Method?

The “5 Whys” it’s a simple yet powerful method often used in various industries and scenarios to delve deeper into problems and uncover their underlying causes. Knowing when to use the “5 Whys” method is crucial for its effective application:

- Repetitive Problems: When faced with recurring problems or issues within a system, process, or workflow, the “5 Whys” method can be employed to uncover the fundamental reasons behind these repetitions. It helps move beyond immediate solutions to address the core issue.

- Complex Situations: In complex situations where multiple factors might contribute to a problem, the “5 Whys” method can help unravel the complexity by systematically identifying interconnected causes.

- Unclear Causes: When the cause of a problem isn’t immediately apparent or is assumed rather than verified, using the “5 Whys” helps in exploring and confirming the actual cause rather than making assumptions.

- Decision-Making Processes: Before implementing solutions or making decisions, especially in situations with substantial consequences or risks, employing the “5 Whys” helps in making more informed decisions by understanding the true cause-and-effect relationships.

- Process Improvement: In process improvement initiatives such as Lean, Six Sigma, or Continuous Improvement, the “5 Whys” are often used to identify inefficiencies, bottlenecks, or defects in processes to enhance overall efficiency and quality.

- Team Collaboration: During team discussions or problem-solving sessions, the “5 Whys” method can encourage collaboration and a deeper understanding of issues by involving multiple perspectives.

- Preventive Measures: The “5 Whys” isn’t just for solving existing problems but also for preventive measures. It helps in identifying potential issues before they occur, allowing proactive mitigation.

- Quality Control: In quality control and assurance, especially in manufacturing or service industries, using the “5 Whys” helps in addressing quality issues by getting to the root cause, leading to more effective corrective actions.

In summary, the “5 Whys” method is best suited for scenarios where a systematic approach is needed to identify the root cause of problems or issues, especially in situations involving recurring issues, complexity, uncertainty about causes, or the need for continuous improvement and problem-solving.

What Is The Origin of 5 Whys Diagram?

The Toyota Production System includes the 5 Whys method. The technique was developed by Sakichi Toyoda, an industrialist and Japanese inventor. It became part of the Lean philosophy.

“Toyota’s scientific approach to solving problems is to ask why five times whenever we find one… If you repeat why five times, it becomes obvious the problem and its solution.” Taiichi Ohno

A well-informed decision is key to the success of this technique. This means that decision-making should be informed by an understanding of the actual situation on the floor. This means that people with real-world experience should be involved in the root cause analysis process. They can provide you with the best information about any problem in their field of expertise.

How to Use the 5 Whys Diagram?

The 5 Whys method may be able to help you achieve continuous improvements at all levels of your company. These are the basic steps to follow.

- Forge a team: Try to get people from different departments together. Each member must be well-versed in the investigation process. You will gain unique perspectives by joining a cross-functional group.

This will allow you to gather enough information to make an informed choice. This is not an isolated task and must be done by the entire team.

- Define the problem: Talk about the problem with your team and create a problem statement. This will allow you to define the issue that you are investigating.

This is crucial because it can be time-consuming to investigate a broad problem with unclear boundaries. To find an effective solution, you need to be as specific as possible.

- Ask Why: One person can be empowered to lead the entire process. The team leader will be asking questions and trying to keep the team on track. Your answers should be based on facts and actual data, not on your emotions.

Facilitators should continue asking “Why” until the team can identify the root cause of the problem.

Do not ask too many Whys. You may get a lot of unfounded suggestions and complaints if you continue to ask. Concentrate on the root cause. Sometimes, there may be more than one cause. The Six Sigma 5 Whys analysis can look more like a matrix, with branches. This could help you identify and fix organizational problems that can have a permanent negative impact on overall performance.

- Get involved: Once the team has identified the root cause, it is time for corrective action. To prevent recurring problems, all members of the team should participate in a discussion.

Once the decision has been made, the responsible person in charge of executing the correct actions and overseeing the entire process should be a member of the team.

After a period, the group should meet again to verify that their actions had any positive effects. If not, it is worth re-doing the whole process.

The case should be documented at the end and sent to all levels of the organization. This information can give a clear overview of the different problems that a team might face and how they can be solved.

Important Things to Remember

- You can work backward to ensure that you have the correct answer for each ” Why”. (Answer the ” What?” + “and consequently” + the Problem Identified for That Question.

- Differentiate causes from symptoms.

- Always base your answers on facts and data.

- It is possible to break down your answers however many times you wish. The more you can answer, the better.

- Last, but not least, evaluate the process and not the people.

The 5 Whys and the Fishbone Diagram

You can use the 5 Whys individually or as part of the fishbone. The fishbone diagram allows you to explore all possible or actual causes that could lead to a defect or failure. Once you have established all the inputs on the fishbone, the 5 Whys technique can be used to drill down to the root cause.