Kaizen is a Japanese philosophy of continuous improvement that focuses on small, incremental changes to processes, systems, and personal development.

The idea behind Kaizen is that small, ongoing changes can lead to significant improvements in the long run. It involves everyone in an organization, from top management to front-line workers, contributing to the process of improvement.

Table of contents

What is Kaizen?

Derived from the Japanese words “Kai” (meaning “change”) and “Zen” (meaning “for the better”), Kaizen emphasizes ongoing progress in every aspect of life, including personal, social, and professional domains. It is a universally applicable philosophy that has been widely adopted in workplaces worldwide, transforming organizational culture by promoting efficiency, innovation, and employee satisfaction.

In the context of organizations, Kaizen ensures that improvements are not just one-time changes but part of a continuous journey. From top executives to front-line workers, everyone is encouraged to actively identify and solve problems, making it a cornerstone of total quality management (TQM).

Core Philosophy

- Kaizen thrives on the notion that small, consistent changes lead to significant improvements over time.

- It emphasizes participation from every level of an organization.

- Improvements are focused on reducing waste, inefficiencies, and redundancies, fostering a culture of problem-solving.

Historical Background

Post-War Origins

Kaizen emerged in Japan after World War II, influenced by American quality management practices, such as the Training Within Industry (TWI) program. These methods emphasized small, practical improvements to maximize limited resources during wartime production.

Introduction in Japan

- The Economic and Scientific Section (ESS) of the U.S. aimed to rebuild Japanese industry by introducing TWI programs.

- Lowell Mellen, a prominent figure in TWI, introduced systematic improvement steps known as “Kaizen no Yon Dankai” (Improvement in Four Steps).

- Dr. W. Edwards Deming, a pioneer in quality management, played a significant role in popularizing Kaizen in Japan, earning the prestigious Order of the Sacred Treasure.

Global Expansion

Over time, it evolved into a comprehensive framework for continuous improvement, spreading to industries worldwide. Its success in Toyota’s Production System (TPS) demonstrated its transformative potential.

Key Concepts

- Continuous Improvement

Kaizen is not about making dramatic changes but focusing on small, consistent improvements over time. These incremental changes cumulatively lead to significant results in productivity, quality, and employee morale. - Inclusivity

Kaizen thrives on the participation of everyone in the organization. Whether it’s a manager optimizing a process or a worker finding a more efficient way to perform a task, every individual contributes to the collective goal. - Standardization and Sustainability

Once an improvement is identified, it is standardized and incorporated into daily operations. This ensures that progress is maintained and serves as a foundation for future improvements. - Problem Awareness

This philosophy treats problems as opportunities for improvement. Instead of ignoring or hiding issues, Kaizen emphasizes identifying root causes and solving them systematically. - Team Collaboration

Collaborative problem-solving is highly encouraged in Kaizen. Team-based efforts foster creativity and a shared sense of achievement, which enhances both the quality of solutions and employee engagement.

Principles

1. Continuous Improvement as a Culture

It is a mindset, not a one-time initiative. Organizations adopting this philosophy ensure that the culture of continuous improvement is deeply embedded in their daily operations.

2. Focus on People

People are at the heart of Kaizen. By empowering employees at all levels to suggest improvements and take ownership of their work, Kaizen creates a motivated and innovation-driven workforce.

3. Incremental Change

Rather than aiming for revolutionary changes, Kaizen focuses on small, manageable steps. These changes are easier to implement and sustain while fostering a sense of progress.

4. Elimination of Waste (Muda)

It prioritizes identifying and eliminating waste in all forms—whether it’s time, materials, or effort. This leads to leaner processes and cost savings.

5. Customer Focus

A key goal of Kaizen is to enhance customer satisfaction. Improvements are directed towards delivering higher-quality products or services efficiently

Approaches

Kaizen can be implemented through various approaches, each addressing specific types of improvements. The two primary methods are Kaizen Blitz and Kaizen Burst.

1. Kaizen Blitz (Point Kaizen)

This method focuses on rapid, localized improvements, often implemented on the spot without extensive planning.

- Characteristics:

- Targets specific areas or processes.

- Implements quick, small-scale solutions.

- Immediate action is taken upon identifying issues.

- Example: A supervisor notices inefficiencies in tool placement during a shop floor inspection and prompts a reorganization to improve workflow.

- Impact: Though small, these changes can have a ripple effect, significantly enhancing overall efficiency.

2. Kaizen Burst (System Kaizen)

This approach addresses system-wide issues through strategic planning and organized efforts.

- Types of System Kaizen:

- Line Kaizen: Focuses on interconnected processes within a single production line.

- Plane Kaizen: Expands improvements across multiple lines or departments, forming a value stream.

- Cube Kaizen: Encompasses the entire organization, connecting all processes and stakeholders, including suppliers and customers.

- Outcome: Cube Kaizen leads to comprehensive transformation, embedding Lean principles across the organization.

Kaizen Methods

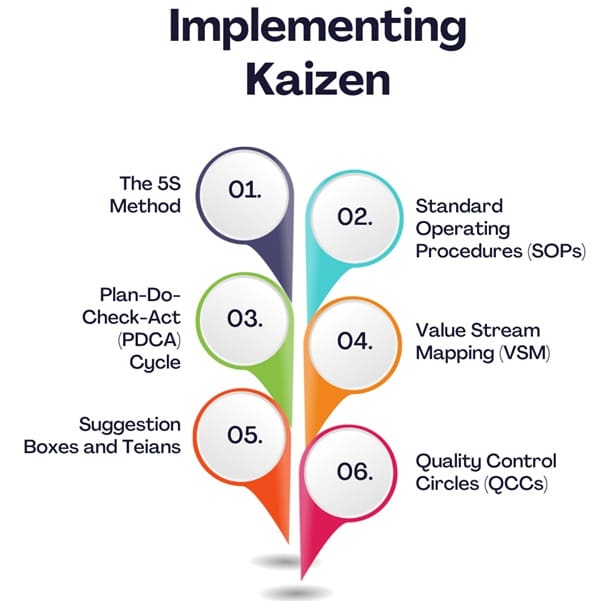

Effective implementation of Kaizen requires structured activities and strategies aimed at workplace standardization. Key methods include:

1. The 5S Method

- Sort, Stabilize, Shine, Standardize, Sustain: These steps help organize the workplace, reduce waste, and enhance efficiency. Integration with Kaizen improves morale, visibility, and safety while minimizing delays (Gupta and Jain, 2014).

2. Standard Operating Procedures (SOPs)

- SOPs provide clear, step-by-step instructions for complex tasks, ensuring consistency and compliance. They form the backbone of Kaizen by establishing standards that facilitate measurable improvements (Berger, 1997).

3. Plan-Do-Check-Act (PDCA) Cycle

- This iterative model drives continuous improvement through systematic problem-solving. By planning, implementing, evaluating, and refining solutions, organizations achieve sustainable advancements (Deming, 1986).

4. Value Stream Mapping (VSM)

- VSM identifies value-adding and non-value-adding activities in a process, highlighting waste and enabling targeted improvements (Banu and Epureanu, 2009).

5. Suggestion Boxes and Teians

- Encouraging employee suggestions fosters innovation and morale. “Teians,” small-scale improvement proposals, enable workers to contribute actionable ideas, leveraging their expertise in specific areas (Kii, 2013).

6. Quality Control Circles (QCCs)

- QCCs involve teams collaboratively identifying and solving problems, focusing on measurable goals. Unlike individual contributions, QCCs reward group efforts, promoting a company-wide improvement mindset (Bacdayan, 2001).

Kaizen vs. Innovation

While Kaizen and innovation both aim for improvement, they differ significantly in their approach:

| Aspect | Kaizen | Innovation |

| Nature | Small, incremental, and ongoing improvements | Breakthrough changes that are often large-scale |

| Focus | Sustained progress | Radical transformation |

| Techniques | Simple, conventional methods | Advanced and cutting-edge technologies |

| Investment | Minimal investment | Requires significant resources and planning |

| Speed | Gradual process | Rapid implementation |

It fosters a steady, long-term culture of improvement, while innovation often results in dramatic, immediate changes.

Implementation of Kaizen in Organizations

Step 1: Problem Identification

The process begins with recognizing areas that require improvement. This could range from operational inefficiencies to quality issues.

Step 2: Root Cause Analysis

Tools such as the Ishikawa Diagram (Fishbone Diagram) or 5 Whys Analysis are used to determine the root causes of problems.

Step 3: Solution Development

Employees brainstorm to create actionable solutions, focusing on simplicity and feasibility.

Step 4: Implementation

Solutions are implemented on a small scale to test their effectiveness. Adjustments are made based on feedback.

Step 5: Standardization

Once validated, the improvement becomes part of the standard operating procedures (SOPs) to ensure consistency.

Step 6: Continuous Review

Regular reviews are conducted to identify further opportunities for improvement, completing the Kaizen cycle.

Benefits

- Enhanced Productivity

By streamlining workflows and eliminating waste, Kaizen improves efficiency and output. - Cost Reduction

Continuous small improvements minimize unnecessary expenditures, leading to significant cost savings over time. - Improved Quality

Incremental changes ensure higher quality in products and services, fostering customer satisfaction. - Employee Engagement

Kaizen empowers employees by involving them in decision-making processes, boosting morale and job satisfaction. - Adaptability

Organizations practicing Kaizen are better equipped to adapt to market changes due to their culture of flexibility and problem-solving. - Competitive Advantage

By focusing on quality and efficiency, companies implementing Kaizen often outperform competitors.

Tools and Techniques

Kaizen utilizes a range of simple yet effective tools for problem-solving and improvement:

- PDCA Cycle (Plan-Do-Check-Act)

- Plan: Identify a problem and develop a strategy to address it.

- Do: Implement the solution on a small scale.

- Check: Evaluate the results.

- Act: Standardize the improvement if successful or revise the approach.

- 5S Methodology

- Sort: Remove unnecessary items.

- Set in Order: Organize the workspace for efficiency.

- Shine: Maintain cleanliness.

- Standardize: Develop norms for organization.

- Sustain: Ensure ongoing adherence to these principles.

- Visual Management

Use of visual cues (e.g., charts, labels) to convey information at a glance, aiding in quick decision-making. - Value Stream Mapping

A tool to analyze current workflows and identify areas for improvement.

Real-World Applications

- Toyota Production System (TPS)

Toyota is one of the pioneers of Kaizen. By focusing on continuous improvement and lean manufacturing, it revolutionized the automobile industry. - Healthcare

Hospitals use Kaizen to improve patient care, streamline administrative processes, and reduce waiting times. - Retail

Retailers apply Kaizen to optimize inventory management, enhance customer service, and reduce waste. - Service Industries

From call centres to financial services, Kaizen has been instrumental in enhancing efficiency and customer satisfaction.

Challenges in Implementing Kaizen

- Resistance to Change

Employees may resist new practices due to fear of failure or discomfort with change. - Short-Term Focus

Organizations may prioritize immediate results over long-term continuous improvement. - Lack of Training

Without proper understanding and training, employees may struggle to contribute effectively to Kaizen initiatives. - Management Commitment

Inconsistent support from leadership can undermine Kaizen’s success.

Kaizen in the Indian Context

In India, the adoption of Kaizen has been growing across industries such as manufacturing, IT, and services. Indian companies are leveraging Kaizen to improve productivity, enhance customer satisfaction, and compete in global markets. However, challenges such as hierarchical structures and limited employee empowerment require tailored approaches to ensure success.

Conclusion

It is more than just a methodology; it is a philosophy that fosters a culture of excellence. By emphasizing small, consistent improvements, Kaizen transforms not only organizations but also the individuals within them. Its widespread applicability and proven benefits make it a valuable tool for achieving sustained growth and innovation in any industry.

Through commitment, collaboration, and continuous learning, Kaizen ensures that no day goes by without making something better.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.