Table of contents

Why don’t we finish our Lean Six Sigma projects?

A Fortune magazine article stated that “60% of Lean Six Sigma projects fail to meet goals” Of 58 large companies that have announced 6 Sigma programs, 91% have trailed the S&P 500.” Aerofil Technology’s President Pat Bergin stated in the company’s August 12, 2010, press release regarding Lean Six Sigma Projects methodology and templates, “Out of every 100 companies who undertake this process, 96 either fail or quit within 18 months.”

Another study published in the Wall Street Journal found that nearly 60% of corporate Lean Six Sigma initiatives fail consistently to meet their corporate goals. This study was done on large companies for a period of five years.

Practice what you preach

Most people are familiar with the phrase “the Cobbler’s children have no shoes.” What I mean is, we as practitioners teach the Lean Six Sigma methodology but we fail to use it when improving our process. Sometimes we get so caught up in teaching the Lean and Six Sigma methodology that we forget that the methodology can improve the outcome of what we teach.

It is no myth that the most difficult “output” of any Lean Six Sigma Implementation is actual consistent project closure. We start the training of our new Green Belt candidates and then set them loose to “fight dragons”, often with weapons that they don’t know how to use.

As MBBs, we teach the methodology and help to implement it; but we often fall into the trap that many college professors fall into. We have an intimate knowledge of what we are teaching and we expect (often subconsciously) our budding belts to fill in the blanks.

Filling the Teacup with a Fire Hose

We expect the potential belts to ask questions, but they often get so much information that they don’t even know how to formulate the questions. This “input” leads to students that go back to work and consistently communicate with an MBB to “fill in the blanks” to complete their projects. Either that or they go back to work, revert to their “reactive” modes and the project is pushed off indefinitely. Thus, project closure becomes an issue.

Solving the problem, the Lean Six Sigma way

Being a Lean Six Sigma practitioner, I took this problem on as a Lean Six Sigma project. The project “Y” was Project Closure Rate. The “Xs” includes many aspects of each belt curriculum, tools, and project structure information.

What I found through data analysis is that belt students want education but still need a formal structure. I took the Voice of the Customer that said, “we need help getting started with our project.”

The solution to increasing project closure rates

The solution to increasing project closure rates was (and is) to provide a detailed roadmap that is the benchmark for a Lean Six Sigma project. We provide that structure to our students in the form of the Lean Six Sigma Green Belt DMAIC (Define, Measure, Analyze, Improve, and Control) Project Roadmap.

The Lean Six Sigma DMAIC roadmap includes:

Project tollgates

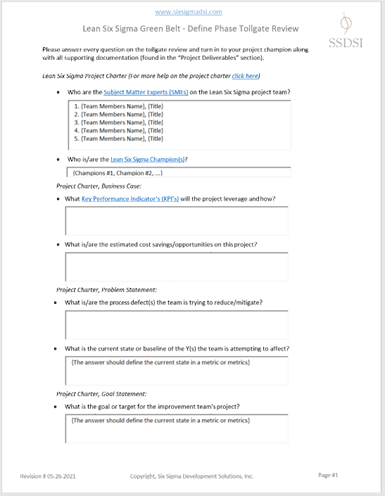

- Lean 6 Sigma Green Belt Project tollgates (a detailed tollgate review for each of the stages of the DMAIC)

Project tollgate example:

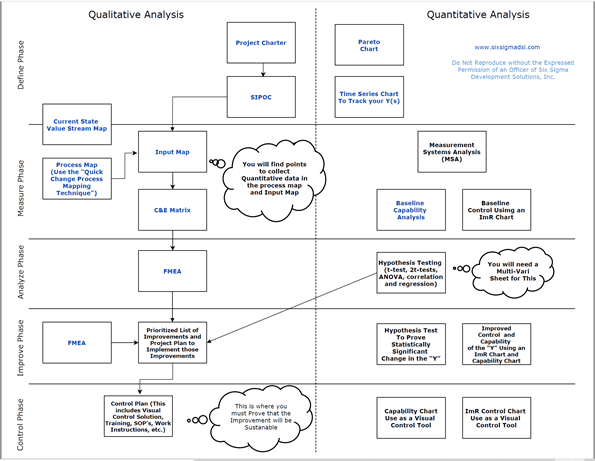

Project flowchart

- DMAIC Lean Six Sigma Green Belt Project flowchart that shows the basic flow of a 6 Sigma Green Belt project

Presentation Template

- A PowerPoint Presentation explains in detail our (SSDSI’s) Lean Six Sigma Green Belt Requirements

Project Template

- A PowerPoint Lean Six Sigma Green Belt Project Methodology Template that can be used as a benchmark

Download a Lean Six Sigma DMAIC roadmap

To download the Lean Six Sigma DMAIC roadmap: https://sixsigmadsi.com/product/six-sigma-green-belt-project-roadmap/.

With these tools, we have seen that our Lean 6 Sigma Green Belt “Project Closure Rate” has increased to 89%. This is well above the 40% benchmark.

What does your organization have in place to increase Project Closure Rates?