Table of contents

What Is Manufacturing Waste and How to Reduce It?

Lean Six Sigma manufacturing has guiding principles that aim to increase revenue by reducing the types of waste management. The bottom line is affected by waste, but its importance has grown in the context of the environment. As green manufacturing gains traction, regulations and reputations will be on the line. Those who continue to operate dirty operations will find themselves increasingly on the wrong side of history.

Competitive manufacturers can reduce lead times, provide a service that is competitive and have less waste while still being environmentally friendly.

What are Manufacturing Wastes?

Manufacturing waste management is defined as any material or resource that has been discarded in the manufacturing process. Manufacturing waste includes excess raw materials and scrap materials. It can also include broken or defective items, energy, or water.

Many manufacturers are aiming to reduce or eliminate this waste in order to improve sustainability and efficiency.

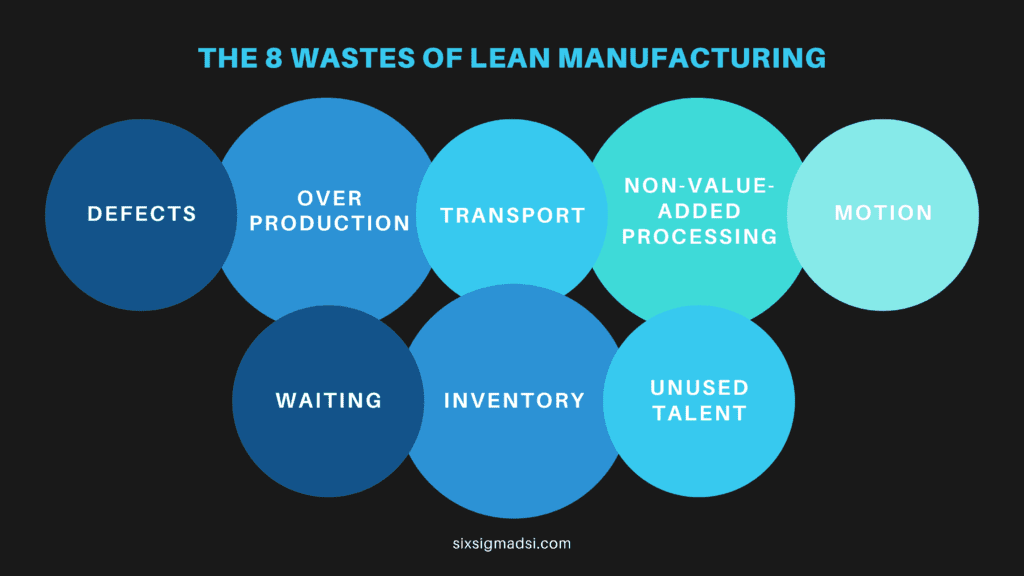

The perception of waste in manufacturing has changed dramatically since the introduction of Lean Manufacturing.

The idea behind Lean principles is to eliminate waste in the manufacturing process. Lean principles demand that you define value, and then divide your processes into two categories based on whether or not they add value to your company and your customers. This allows you to reduce manufacturing waste by identifying and systematically reducing it.

How can you reduce waste and increase manufacturing productivity?

Using the classification above, you can determine the type of waste that you produce the most, regardless of your industry.

The specifics vary from one industry to another. Material waste is created by perishable stock that has expired in the manufacturing industry. In textile and Metal Manufacturing waste is generated from scraps. The first step is to map out your waste streams.

After you’ve clarified this, you can then move on to other ways you can reduce waste.

How to Reduce manufacturing waste in 11 effective ways

1. Efficient Inventory Management

Reduce manufacturing waste by controlling the amount of materials used during manufacturing management. This includes raw materials, work in progress, and finished products. To reduce waste, you can reduce the stock of excess raw materials and hazardous materials. Only order the amount of material required for production or to meet customer demand over a certain period.

Avoid making unnecessary purchases. Estimate how much to produce based on your past sales. Discover your most profitable products and the ones that are not as popular so you can produce them this time.

2. Waste Reduction Audits

Audits can provide valuable insight into the equipment’s usage and possible improvements. Audits of equipment usage, for instance, can detect increased wear and tear on components that are already susceptible to failure. These plates increase the lifespan of replaceable parts, reducing cost year after year.

It is also important to consider how employees operate machinery. Training ensures that everyone is using equipment correctly. A deviation from the recommended usage may cause machinery to operate harder than it was intended and expose more delicate parts to wear. The turnover of employees can lead to a shortage of workers who are able to operate heavy machinery. High turnover in a bad year can lead to a greater impact on productivity, especially if the machinery breaks down due to improper use.

3. Plan Production Properly

Some factory owners cut production hours to reduce idle time. In some cases, reducing manpower may be the best option. However, idle time can increase productivity in other areas. Retraining engineers and line workers as amateur technicians to maintain and evaluate the line is possible. It is usually cheaper to repurpose employees and give them a small pay increase than hire a full-time or third-party employee.

Plan your production around products that are likely to sell. Under-utilization of materials is one of the easiest ways to create waste. It also applies to product development where too many features can confuse the purpose of a product and make it difficult to sell. Thinking Lean is about creating a product to meet a specific need while being granular in the way you approach it.

4. Reducing Lead Times

Simple adjustments, such as improvements to your IT infrastructure, will have a positive impact on the supply chain and can reduce lead times. This helps you to stay competitive and gives a better estimate of when the product will hit the shelves.

You can also improve your supply chain to be ready for any situation. Material suppliers will be more willing to cooperate with you if you place regular orders, particularly in large quantities. Standardizing certain components is another option, and it works better when you use the same vendors. Even standardizing a small screw or internal component, can improve turnaround time and reduce costs.

5. Identification of Major Waste Sources

Examine your own supply chain and see if you can find any useful information. Be sure to consider the costs of personnel, materials, and transport.

You should ensure that your staff is well-trained, and operating at maximum efficiency. Reducing workers to fit the production schedule is important. Be prepared to hire seasonal staff as required. Recruiters are able to help fill seasonal positions with contract workers.

6. Maintain and improve

Lubricants are a great way to save money over the long term. Investing in lubricants will keep the machinery running smoothly, and prevent unnecessary wear to fragile parts. Excess lubricant can cause machinery to jam. The use of lubricant forces technicians to continually evaluate machinery.

The teams that maintain their machinery properly at regular intervals will be more likely to detect the cause of a more costly problem before it becomes uncontrollable. The management should set up a system that employees can use to report when something is broken or in danger. The first step to reducing major repair costs is to document existing problems.

7. Reduce packaging

Avoiding a problem before it manifests is better. To avoid waste, focus on durable products or those that can be reused. To avoid unnecessary purchases, implement a more accountable system of purchasing.

Packaging is important to make products appealing, but it also contributes significantly to waste. Packaging should be limited to the bare minimum. Encourage your suppliers to do the same when packaging products for you.

8. Recover, Reuse, and Sort

Utilize different techniques such as reverse osmosis (RO), centrifugation, and electrolysis to recover the maximum amount of waste possible from both onsite and offsite sites.

Avoid recycling hazardous materials, as they rarely have any environmental benefits. In this process, industrial shredders can reduce waste by reducing the size of asphalt, wood rubber, and plastics.

9. Preventive maintenance is the Best

Preventive maintenance is an important tool that’s often overlooked. Regular maintenance is essential. Consider how you store raw materials. Stocking only a reasonable amount of material, keeping it close to the final destination, and following recommended storage guidelines can help prevent spills and waste.

Upgrade your system to a more intelligent one if possible. Check your filtration and the ease of cleaning, according to recommended guidelines.

10. Manage Bins Better

The placement of waste bins in all business establishments is a critical part of waste management. The addition of recycling bins can help reduce manufacturing waste. Put a recycling bin near every trash can.

Label your bins clearly so that you can ensure that the staff uses them appropriately. Images of the materials that can be placed in either bin will help to make your message more clear. It is important to differentiate between trash cans and recycling bins. Consider using signage to encourage your employees to recycle. This is best placed near recycling bins.

11. Reduce water usage

Reduce the use of water and other solvents. Lean Manufacturing waste streams are dominated by industrial sludges and wastewater management. These elements can be reduced by reducing the amount of water used in your operations. You can achieve this by using dry machining or membrane biological reactors, as well as chemical drying agents. Monitor your water usage and optimize your processes to use less.

Encourage employees to reduce the amount of water they drink in plastic bottles, as these bottles make up a large part of the plastic waste produced. Instead, encourage them to use reusable bottles and glasses at work.

What is the most common type of waste you’ve encountered during your Lean Six Sigma project?

Tell us about it in the comments below!