Table of contents

Estimated reading time: 7 minutes

What is a Loss Tree Analysis?

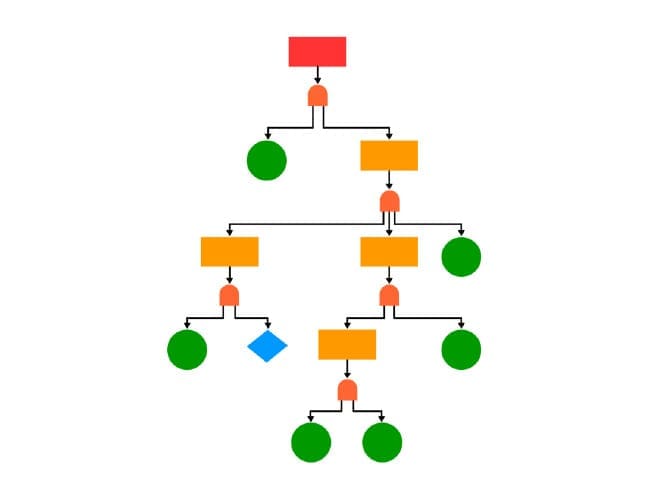

In the realm of systematic analysis methodologies, the Fault Tree Analysis (FTA) stands as a vital tool for understanding failures and their root causes within complex systems. Rooted in the principles of FTA, a Loss Tree Analysis (LTA) extends this approach to encompass a broader spectrum of losses and inefficiencies across various industries, using fault tree analysis symbols to expand its reach. But what exactly is a Loss Tree Analysis, and how does it differ from Fault Tree Analysis?

Understanding Loss Tree Analysis

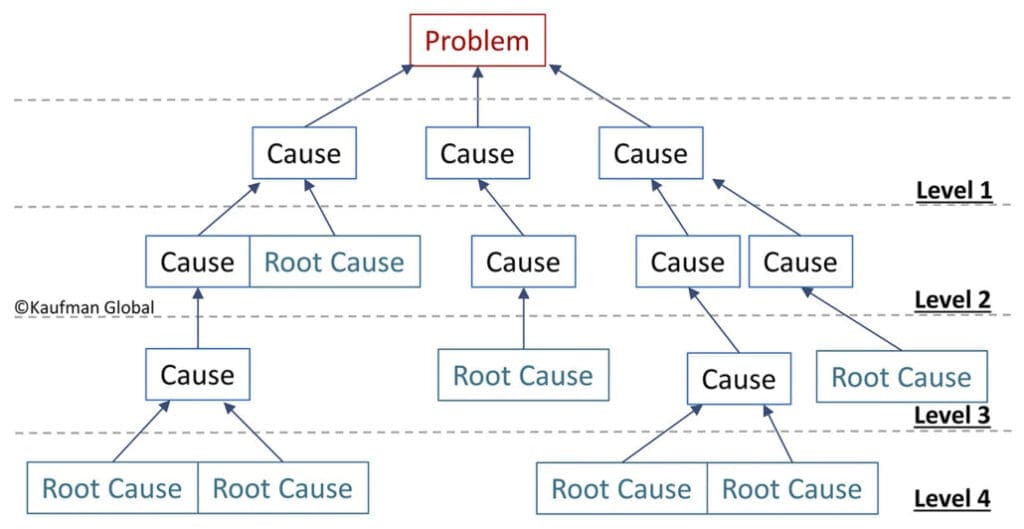

In simple terms, a Loss Tree Analysis is a systematic method used to identify, categorize, and analyze losses that affect the overall performance, efficiency, and reliability of systems, processes, or equipment within an organization. It delves deeper into understanding not only failures but also a wide array of losses that impact different facets of operations, utilizing fault tree analysis symbols to symbolize relationships and dependencies between these various losses.

Initially derived from Fault Tree Analysis, which focuses primarily on identifying the causes of system failures, Loss Tree Analysis broadens its scope to encompass multiple categories of losses and their interdependencies. Employing specific symbols akin to Fault Tree Analysis symbols, a Loss Tree delves into various losses beyond technical failures, embracing factors like human error, resource inefficiencies, and operational bottlenecks.

Evolution and Purpose

Initially derived from Fault Tree Analysis (FTA), which originated in the 1960s within the aerospace and nuclear industries, Loss Tree Analysis evolved as a response to the limitations of FTA. FTA primarily focused on identifying system failures and their causes using a tree-like diagram structure. However, it had constraints in addressing broader operational inefficiencies and losses beyond technical faults.

Recognizing these limitations, practitioners sought to expand the scope of fault analysis methodologies to encompass a wider spectrum of losses affecting overall system performance. This evolution led to the development of Loss Tree Analysis, allowing for a more comprehensive examination of various types of losses impacting different facets of operations within organizations.

The primary purpose of Loss Tree Analysis is to provide a systematic and structured approach to identify, categorize, and analyze a multitude of losses that affect organizational performance. Unlike its predecessor, FTA, which primarily focused on technical failures, LTA broadens its scope to encompass diverse categories of losses, including human errors, resource inefficiencies, and operational bottlenecks.

In essence, the evolution of Loss Tree Analysis from Fault Tree Analysis signifies a paradigm shift from solely focusing on technical failures to a more holistic approach that encompasses a wide array of losses affecting organizational performance. Its purpose remains deeply rooted in providing a structured methodology to identify, analyze, and mitigate losses, thereby fostering continuous improvement and optimizing overall operational effectiveness.

Types of Losses

Six Major Losses Reducing Equipment Effectiveness

- Equipment Failures: Malfunctions or breakdowns in machinery.

- Setup and Adjustment Losses: Time lost during changeovers or adjustments.

- Idling and Minor Stoppages: Short pauses or delays in operations.

- Reduced Speed Losses: Operations running slower than their potential.

- Defects and Rework: Products requiring rework due to defects.

- Unutilized Time and Capacity: Unused potential in resources or capacity.

Losses Impeding Machine Reliability

Instances such as inadequate maintenance, improper handling, or lack of proper training causing machine-related failures.

Man Losses

Human errors, inefficiencies, lack of training, or inadequate supervision leading to losses in productivity or quality.

Three Losses Affecting Effective Resource Utilization

- Material Losses: Wastage or loss of materials in the production process.

- Energy Losses: Inefficient usage or loss of energy resources.

- Time Losses: Ineffective use of time leading to inefficiencies.

Understanding these losses allows organizations to take a targeted approach in identifying and mitigating the underlying causes, thereby enhancing overall operational efficiency.

Methodology and Framework

A Loss Tree is constructed through a systematic process involving identification, classification, and analysis of various losses, incorporating fault tree analysis symbols to illustrate the relationships. It entails mapping out the connections and dependencies between different loss categories using a graphical representation, allowing for a clear understanding of the interdependencies and their impact on overall performance.

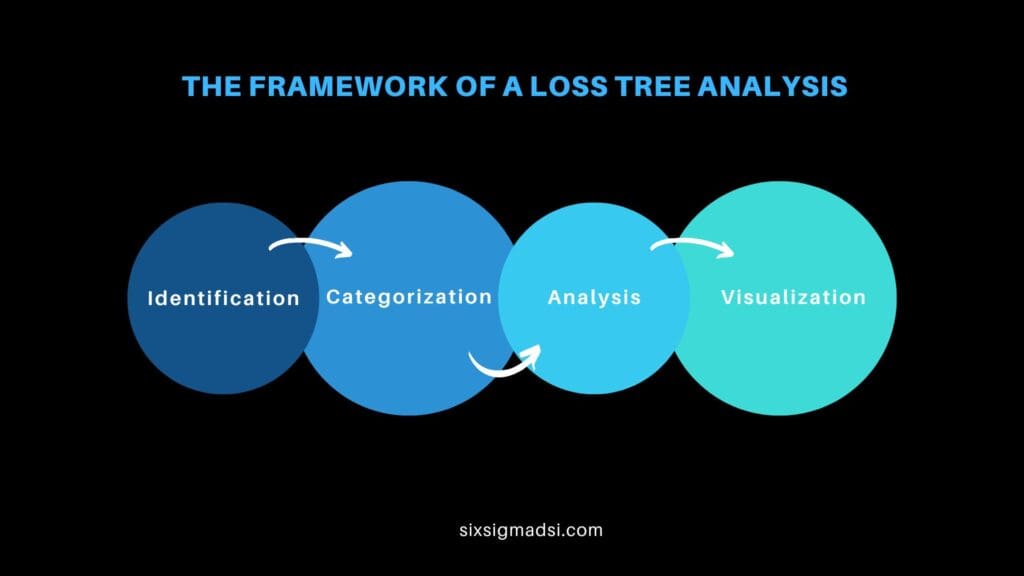

The framework typically involves:

- Identification: The first step involves gathering data and information related to different types of losses within the organization. These losses can be categorized into various groups, including but not limited to equipment failures, human errors, resource inefficiencies, and operational bottlenecks. Data collection may involve historical records, performance metrics, incident reports, and stakeholder inputs.

- Categorization: Once the losses are identified, they are categorized into distinct groups or subgroups based on their nature and impact. For instance, equipment-related losses might encompass breakdowns, downtime, or maintenance issues, while human-related losses might involve errors, inadequate training, or absenteeism. Categorization aids in organizing and better understanding the different types of losses.

- Analysis: The core aspect of the Loss Tree framework involves analyzing the relationships and interdependencies between various loss categories. This step aims to understand how different types of losses interact and influence each other within the organizational context. For instance, equipment failures might lead to production downtime, which in turn affects resource utilization and efficiency.

- Visualization: Visual representation is key in Loss Tree Analysis. A Loss Tree diagram, resembling a tree-like structure, is created to depict the relationships between different loss categories. Typically, the diagram is constructed with nodes representing different types of losses and arrows indicating the cause-effect relationships or interdependencies between them. This graphical representation aids in visualizing the complex network of losses within the organization.

When to Use a Loss Tree Analysis

A Loss Tree Analysis finds applicability across diverse industries, including manufacturing, healthcare, logistics, and more. For instance, in manufacturing, it aids in optimizing production processes, while in healthcare, it assists in identifying and mitigating risks to improve patient care.

Successful Applications

Case studies exemplify the successful application of Fault Tree Analysis. One such instance involves a manufacturing firm that utilized LTA to identify and rectify machine reliability issues, subsequently increasing production efficiency by 20%. Another example comes from the logistics sector, where LTA helped streamline warehouse operations, reducing resource wastage by 15%.

Benefits and Importance

The advantages of employing Fault Tree Analysis span various aspects of organizational management. It facilitates informed decision-making, risk mitigation, and resource optimization. Moreover, its systematic approach enables a proactive stance toward problem-solving and continuous improvement.

The importance of LTA extends to:

- Risk Management: Identifying potential risks and their impact on operations.

- Decision-making: Providing data-driven insights for effective decision-making.

- Efficiency Improvement: Streamlining processes to reduce losses and enhance productivity.

- Cost Reduction: Mitigating losses can lead to significant cost savings over time.

Loss Tree Analysis Tips and Best Practices

- Ensure cross-functional team involvement for diverse perspectives.

- Use standardized symbols and terminology for consistency.

- Regularly update and reassess the Loss Tree for relevance and accuracy.

- Document findings and recommendations for future reference and improvement.

- Encourage a culture of continuous improvement and learning within the organization.

Recommendations

In conclusion, implementing a Loss Tree Analysis can significantly benefit organizations across industries by providing a structured approach to identifying and mitigating losses. To ensure effective implementation, it is crucial to foster a culture of continuous improvement and utilize the findings to drive actionable strategies for enhanced performance and efficiency. Embracing Fault Tree Analysis as a proactive tool, along with the utilization of fault tree analysis symbols, can empower organizations to navigate challenges and optimize their operations for sustained success.