Gemba is a Japanese term that means “the real place.” It refers to the actual location where businesses create value. In manufacturing, this is often the factory floor where products are made, while in healthcare, it could be a hospital ward or clinic where services are delivered to patients.

The concept of Gemba encourages leaders to physically go to the place where the work happens, observe the process, and engage with employees. Toyota originally introduced this idea and later popularized by management thinkers like Tom Peters through his concept of Management by Wandering Around (MBWA).

While Gemba and MBWA share the practice of management visiting the front lines, Gemba is more focused and purpose-driven. Leaders should understand how value flows across the organization and identify areas where inefficiencies or waste may exist. This awareness helps them make targeted improvements.

Table of contents

- Purpose of Gemba Walk

- What is a Gemba Walk?

- Gemba Walk Process

- Approach

- Goal of a Gemba Walk

- How to Implement a Gemba Walk?

- Conducting an Effective Gemba Walk

- Sustaining Continuous Improvement After the Gemba Walk

- Importance of Asking the Right Questions

- Gemba Walks and Lean Management

- Final Words

- Related Articles

Purpose of Gemba Walk

A Gemba Walk improves processes by observing the actual place where value is created. It involves engaging with employees and identifying areas for improvement.

The primary goal is not to point out mistakes or make immediate corrections but to foster a deeper understanding of the processes in place and to gather insights from workers who perform these tasks daily.

During the Walk, managers should look for ways to eliminate waste, streamline processes, improve safety, and enhance the overall workflow.

This method provides a fresh perspective that can be difficult to achieve from behind a desk. By observing real-time operations, managers understand the challenges their employees face. They become better equipped to offer solutions that improve productivity and quality.

What is a Gemba Walk?

A Gemba walk involves managers and leaders visiting the actual place where work is performed to observe and understand processes. The term “Gemba” (or “Genba”) is Japanese for “the actual place” or “the real place.” This is where work happens and value is created.

In manufacturing, a Gemba walk usually means going to the shop floor. However, it’s not limited to this environment. Gemba walks can be applied in offices, construction sites, and salesrooms.

The main goal of a Gemba walk is for managers and leaders to gain firsthand insight into work processes. They identify areas for improvement and engage directly with workers.

A Gemba walk is not a fault-finding mission. Instead, it aims to understand work processes and find ways to improve them. It focuses on enhancing processes, reducing waste, and increasing overall efficiency. Observation, engagement, and a deeper understanding of the work environment are key elements.

Importance

The Gemba walk is crucial for fostering a culture of continuous improvement in an organization. It helps bridge the gap between theory and practice by allowing managers to see real-world operations and identify deviations from standard operating procedures (SOPs).

These walks enable managers to spot inefficiencies, safety hazards, and potential areas for process innovation.

It is not just about finding problems but are also about creating opportunities for improvement and fostering collaboration between different levels of an organization. Whether you’re a top-level manager, team leader, or floor-level employee, the Gemba walk has distinct benefits:

Top-Level and Middle Management:

- Improved Productivity: By observing the workflow and interacting with employees, managers can identify bottlenecks and inefficiencies, leading to better resource allocation and process optimization.

- Increased Overall Equipment Effectiveness (OEE): Managers can detect issues affecting equipment performance and take proactive steps to prevent breakdowns and optimize maintenance schedules.

- Enhanced Safety: Regular Gemba walks can help identify safety hazards and ensure compliance with health and safety regulations.

- Autonomy for Lower-Level Management: Gemba walks promote a shift from reactive problem-solving to proactive supervision, allowing team leaders and workers to take more ownership of their processes.

Team Leaders:

- Proactive Supervision: Gemba walks encourage leaders to shift their focus from solving problems after they occur to identifying and preventing them in advance.

- Credibility and Engagement: Team leaders who regularly engage with their teams on the shop floor build trust and credibility, leading to better collaboration and problem-solving.

- Time for Improvement Projects: By reducing time spent on firefighting and reactive problem-solving, team leaders can focus more on long-term improvement initiatives.

Floor-Level Employees:

- Visible Solutions: Employees feel heard when management actively observes their challenges and works to find solutions.

- Reduced Stress: Addressing day-to-day issues promptly reduces downtime and waiting time, leading to smoother operations and a more positive work environment.

- Increased Feedback: Gemba walks provide employees with an opportunity to give direct feedback on tools, processes, and workflows.

Gemba Walk Process

It is not a one-time event. It is a continuous process. Managers should incorporate it into their regular routine. The key is to approach it with the right mindset and follow a structured plan:

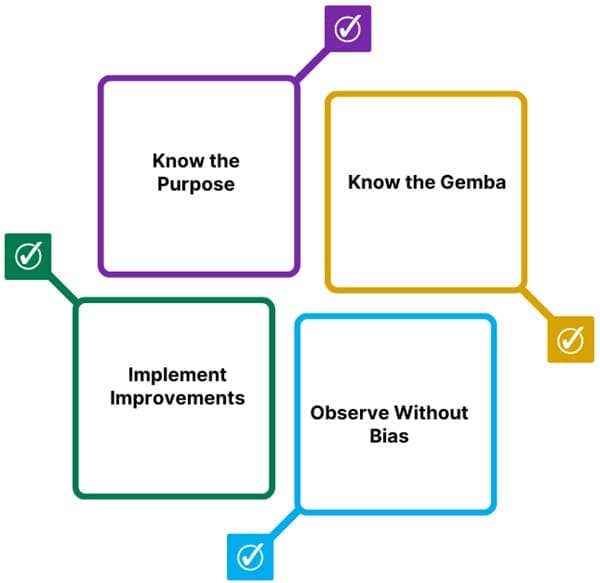

1. Know the Purpose

Before conducting a Gemba Walk, it is essential to have a clear purpose. Each walk should focus on a specific aspect, while the general goal is to understand how the business creates value. For example, a manager might want to assess the efficiency of a particular production line, examine safety protocols, or identify sources of waste.

Rather than trying to evaluate the entire operation in one go, it’s more effective to break down the Gemba Walk into manageable segments, focusing on different areas over time. This approach allows for a more thorough examination and ensures that each aspect of the business receives proper attention.

2. Know the Gemba

To properly assess a process, managers must first understand it. This means having a good knowledge of the core activities and functions that take place in the organization. Gemba isn’t limited to a single location.

In manufacturing, it might be the production line, while in customer service, it could be the call center or help desk. Each Gemba has its own unique processes and challenges, and it’s important to be familiar with these before conducting a walk.

Schedule regular Gemba Walks across different areas of the business. This ensures that we observe all critical functions. Managers develop a comprehensive understanding of how value is created.

3. Observe Without Bias

When conducting a Gemba Walk, it’s crucial to approach the process without preconceived notions or biases. The goal is to understand how things are done and why they are done that way, not to find fault or assign blame. A successful Gemba Walk involves open-minded observation, active listening, and engagement with employees.

Questions to ask during a Gemba Walk might include:

- What is working well?

- Are there any areas where value is being lost?

- Are processes being followed as intended?

- Are there any inefficiencies or variations in the process?

- How does this step in the process add value for the customer?

Managers use these questions to focus on key aspects of the operation. They encourage employees to share their perspectives on improving the process.

4. Implement Improvements

The final step in the Gemba Walk process is to take the insights gained during the walk and use them to make meaningful improvements. This could involve streamlining workflows, reducing waste, improving safety, or enhancing employee training. The goal is to create a culture of continuous improvement, where employees and managers work together to identify and solve problems.

Gemba Walks should not be about immediate fixes or quick wins. Instead, they are part of a long-term strategy to improve the overall efficiency and effectiveness of the organization.

Approach

The success of a Gemba walk hinges on the manager’s approach. When managers approach Gemba walks with genuine interest, employees feel respected. They are more likely to open up, share insights, and actively participate in discussions about improvement.

On the other hand, if the Gemba walk feels like an inspection or an opportunity to point out errors, it can breed mistrust and discourage collaboration.

Managers should focus on three key elements during their walk:

- Purpose: Understanding the organisation’s broader objective and how specific tasks contribute to achieving that goal.

- People: Engaging with employees, asking questions, and showing respect for their expertise.

- Process: Observing how work is carried out and identifying areas where improvements can be made.

Goal of a Gemba Walk

The main goals of a Gemba walk are twofold:

- Identify and Solve Issues: Managers and leaders aim to detect problems before they escalate into larger issues. By observing the processes firsthand, they can uncover inefficiencies, waste, and potential hazards that may not be visible from a distance.

- Generate Improvement Opportunities: Gemba walks are also about identifying areas where processes can be enhanced. This might involve introducing new tools, streamlining workflows, or updating standard procedures to align better with actual practices.

How to Implement a Gemba Walk?

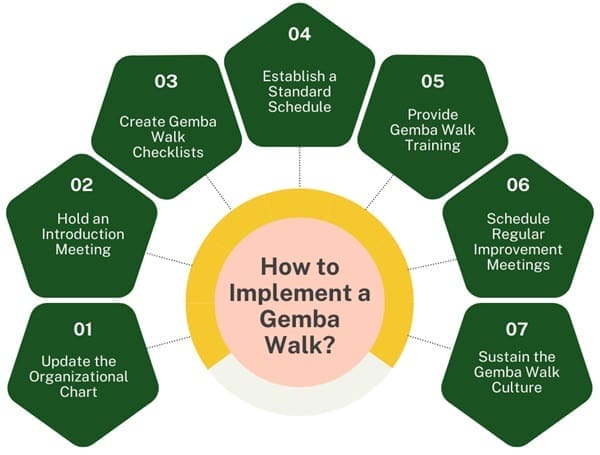

To maximize the effectiveness of a Gemba walk, it must be structured and consistent. Here’s a step-by-step guide on how to implement a Gemba walk within an organization:

1. Update the Organizational Chart

The first step in implementing a Gemba walk is to ensure that the company’s organizational chart is up to date. This helps clarify roles, responsibilities, and accountability.

2. Hold an Introduction Meeting

Top executives should conduct an introduction meeting. They should explain the purpose and benefits of Gemba walks. This meeting is crucial to reduce resistance to change and ensure buy-in from team leaders and employees.

3. Create Gemba Walk Checklists

Each team leader should develop a checklist of items to review during the Gemba walk. They should collaborate with management to create this checklist. The checklist aims to identify inefficiencies and waste in the workplace. Communicate to employees that these walks aim to support continuous improvement. Emphasize that they are not intended to punish employees.

4. Establish a Standard Schedule

For Gemba walks to be effective, they should be conducted regularly. A typical schedule involves team leaders performing Gemba walks four times a day, while middle management should conduct two walks per day.

5. Provide Gemba Walk Training

Each team leader should receive training on how to conduct an effective Gemba walk. This involves shadowing their walks and offering guidance to ensure that they are asking the right questions and observing processes correctly.

6. Schedule Regular Improvement Meetings

At least once a week, managers should meet with team leaders to review the findings from the Gemba walks and to discuss progress on improvement projects.

7. Sustain the Gemba Walk Culture

Continuous improvement requires a sustained effort. Managers should set goals for how many improvement opportunities team leaders should identify each week.

Conducting an Effective Gemba Walk

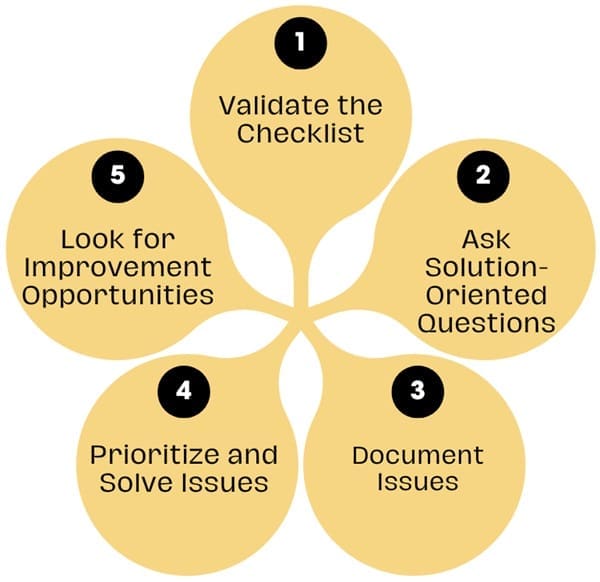

An effective Gemba walk involves more than just walking around the shop floor. It requires purposeful observation, engagement with employees, and a focus on uncovering opportunities for improvement. Here are the key steps for conducting a successful Gemba walk:

- Validate the Checklist: Team leaders should check all the points on their Gemba walk checklist to ensure that they are identifying potential issues and opportunities for improvement.

- Ask Solution-Oriented Questions: Instead of focusing on who is at fault for any issues, ask questions that help identify the root cause of problems and potential solutions. For example, if an employee is unsure about the quality standards for a job, ask questions like, “What is the color code for this task?” or “How many pieces are in this batch?”

- Document Issues: If you identify a problem, document it with relevant details. Avoid interrupting the workflow during the Gemba walk.. Instead, prioritize and address issues after the walk is complete.

- Prioritize and Solve Issues: After the walk, evaluate the risks and impacts of each issue. Prioritize them in the order they should be addressed. Solving high-priority issues promptly prevents them from becoming larger problems.

- Look for Improvement Opportunities: Once the team resolves immediate issues, focus on identifying long-term improvement opportunities. This could involve standardizing processes, implementing new tools, or restructuring workflows to prevent future issues.

Sustaining Continuous Improvement After the Gemba Walk

Once the Gemba walk is completed, it’s important to take action on the findings. Here are some steps to sustain the culture of continuous improvement:

- Follow-Up on Issues: Ensure that the team addresses all identified problems and implements the solutions effectively.

- Conduct Weekly Improvement Meetings: The plant or operations manager should hold regular meetings with team leaders to review progress on improvement plans and to discuss new opportunities for improvement.

- Monitor Progress: Regularly review the results of Gemba walks and track how they contribute to improving productivity, safety, and overall equipment effectiveness.

Importance of Asking the Right Questions

Asking the right questions is critical to the success of a Gemba walk. Managers should avoid leading questions that suggest a particular answer or solution. Instead, they should ask open-ended questions that encourage employees to share their insights and perspectives.

Some examples of questions to ask during a Gemba walk include:

- What challenges do you face in completing this task?

- Are there any steps in this process that feel unnecessary or inefficient?

- How does this process contribute to the overall value we deliver to our customers?

- Is there anything you think could be done differently to improve this process?

These questions encourage employees to think critically about their work and share their ideas for improvement.

Gemba Walks and Lean Management

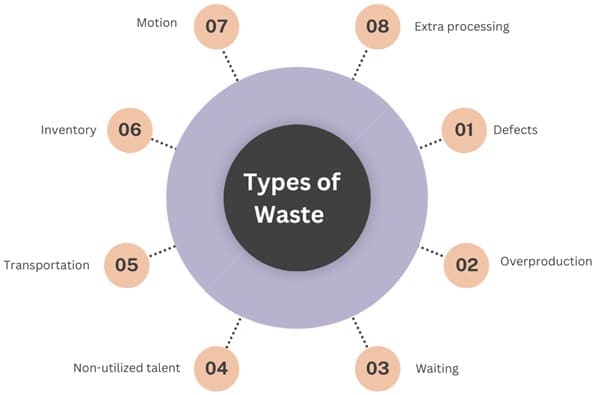

Gemba walks are a core component of Lean management, which focuses on maximizing value while minimizing waste. In Lean thinking, value is anything that contributes to solving a customer’s problem, while waste is anything that does not add value. Gemba walks allow managers to see firsthand where waste exists in their processes and take steps to eliminate it.

By conducting Gemba walks, managers can identify the eight types of waste in Lean management:

- Defects: Errors or mistakes that require rework.

- Overproduction: Producing more than is needed or earlier than required.

- Waiting: Idle time when employees or machines are not working.

- Non-utilized talent: Underutilizing employees’ skills and capabilities.

- Transportation: Unnecessary movement of materials or products.

- Inventory: Excess materials or products that are not immediately needed.

- Motion: Unnecessary movement by employees.

- Extra processing: Doing more work than is necessary to meet customer needs

Final Words

A Gemba walk is a powerful tool for promoting continuous improvement in any organization. By observing work processes in their actual environment, engaging with employees, and identifying areas for improvement, managers can make more informed decisions and drive positive changes.

The success of a Gemba walk depends on its structure, regularity, and the commitment of all levels of management. When done correctly, it solves immediate issues.It creates a culture of continuous improvement. Everyone actively participates in making the organization more efficient and effective.

By fostering open communication, encouraging proactive supervision, and prioritizing process improvements, the Gemba walk ensures that businesses remain adaptable, resilient, and focused on delivering value.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.

Hello, is this statement accurate: “Is it workers who are waiting for machines or machines that are waiting for workers? The former is fine, but the former should never be allowed.”

TK, Great statement. Machines that are waiting for workers coupled with not meeting demand is a constraint in the system. Workers wsainiting on machines could also be a constraint is demand is not being met. We need to know our performance to TAKT time first before we can make the determination.