Table of contents

Estimated reading time: 7 minutes

What are Inspection Plans?

In any production or manufacturing process, ensuring the quality of products is paramount. Inspection test plans play a crucial role in maintaining and enhancing product quality by systematically assessing and monitoring various aspects of the production process. It can be defined as a structured set of instructions and procedures designed to evaluate, control, and improve the quality of products or processes. The primary goal is to identify and rectify any deviations or defects that might compromise the desired quality standards.

Types of Inspection Plans

- Receiving Inspection Plan: Focuses on evaluating incoming materials or components to ensure they meet predefined quality criteria before being incorporated into the production process.

- Resource Inspection Plan: Involves the assessment of machinery, equipment, or tools used in the manufacturing process to guarantee their proper functioning and adherence to safety standards.

- Inventory Inspection Plan: Aims to maintain the quality of stored goods and materials, preventing deterioration or damage during storage.

- Work in Process Inspection Plan: Monitors the quality of products at various stages of the production process, enabling early detection and correction of defects.

- Asset Inspection Plan: Concentrates on evaluating long-term assets such as facilities or infrastructure to ensure their ongoing reliability and compliance with regulations.

Benefits of Following Inspection Plans

Following inspection plans offers a multitude of benefits that contribute to overall operational efficiency and product quality. The three main advantages include:

- Risk Avoidance: The risk of overlooking quality issues is significantly reduced, ensuring that only products meeting the required standards proceed through the production pipeline.

- Efficient Corrective Actions: Inspection plans facilitate the timely identification of defects, enabling corrective actions to be implemented without disrupting the entire production schedule. This proactive approach minimizes downtime and production delays.

- Operational Efficiency: Provide a structured and systematic approach, streamlining the quality assurance process and enhancing overall operational efficiency.

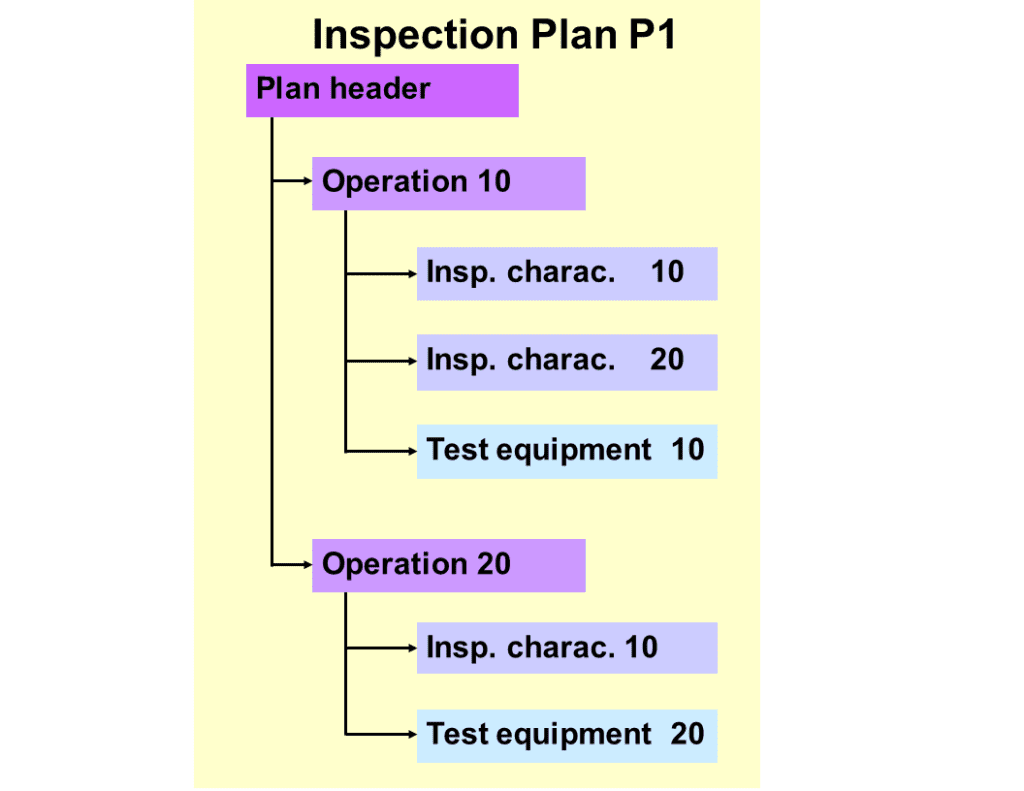

Features of Inspection Plans

- Task List Groups: Simplify management and execution.

- Characteristic Definition: Characteristics to be inspected are clearly defined, outlining the specific quality criteria for evaluation.

- Header Information: General data is stored in the header, providing a comprehensive overview of the inspection parameters.

- Material Assignment: Multiple materials can be assigned to a single inspection plan, streamlining the assessment process for diverse products.

- Vendor/Customer Assignment: Inspection plans can be assigned to multiple vendors or customers, ensuring comprehensive quality control throughout the supply chain.

- Historical Tracking: The ability to check the status of an inspection plan at any key date provides valuable historical data for analysis and improvement.

Why are Inspection Plans Important?

The inspection plan serves as a critical component, indicating whether the manufacturing process is operating within the desired parameters. For those committed to achieving Six Sigma goals, it becomes an indispensable tool for ensuring continuous improvement and adherence to quality standards.

- Quality Assurance: By systematically evaluating and monitoring key parameters at different stages of production or service delivery, organizations can identify and rectify any deviations from quality standards.

- Process Control: Inspection plans provide a structured framework for controlling and monitoring manufacturing or service processes. They help ensure that each step in the production or service delivery chain adheres to predefined quality criteria, minimizing the likelihood of defects and errors.

- Compliance with Standards: Many industries have stringent regulatory and quality standards that must be met. Inspection plans serve as a tool to verify compliance with these standards, ensuring that products or services align with industry regulations and customer expectations.

- Early Detection of Defects: By conducting inspections at various stages of production, inspection plans enable the early detection of defects or deviations from quality specifications. This early identification allows for prompt corrective actions, preventing the production of substandard products and reducing waste.

- Continuous Improvement: Inspection plans are integral to a culture of continuous improvement.

- Customer Satisfaction: Meeting or exceeding customer expectations is a key objective for any business.

- Risk Mitigation: By systematically assessing and addressing potential quality issues, organizations can mitigate the risk of defects, recalls, and customer dissatisfaction. This, in turn, protects the organization’s reputation and bottom line.

- Data-Driven Decision Making: Generate data that can be analyzed to make informed decisions. Organizations can use this data to identify trends, patterns, and areas for improvement, fostering a data-driven approach to quality management.

- Supply Chain Management: In industries with complex supply chains, inspection plans extend beyond the organization’s boundaries. They ensure that incoming materials and components from suppliers meet specified quality standards, contributing to a seamless and reliable supply chain.

- Six Sigma and Lean Initiatives: They provide measurable data for process improvement, helping organizations achieve higher levels of efficiency, consistency, and customer satisfaction.

Inspection Plan Best Practices

- Clearly Identify Areas of Concern: Focus on specific areas that are critical to quality and clearly identify potential concerns to address during the inspection.

- Clear Defect Removal Plan: Develop a well-defined plan for removing and correcting identified defects, ensuring a swift and effective response to quality issues.

- Continuous Improvement: Embrace a mindset of continuous improvement, refine processes, and enhance overall product quality.

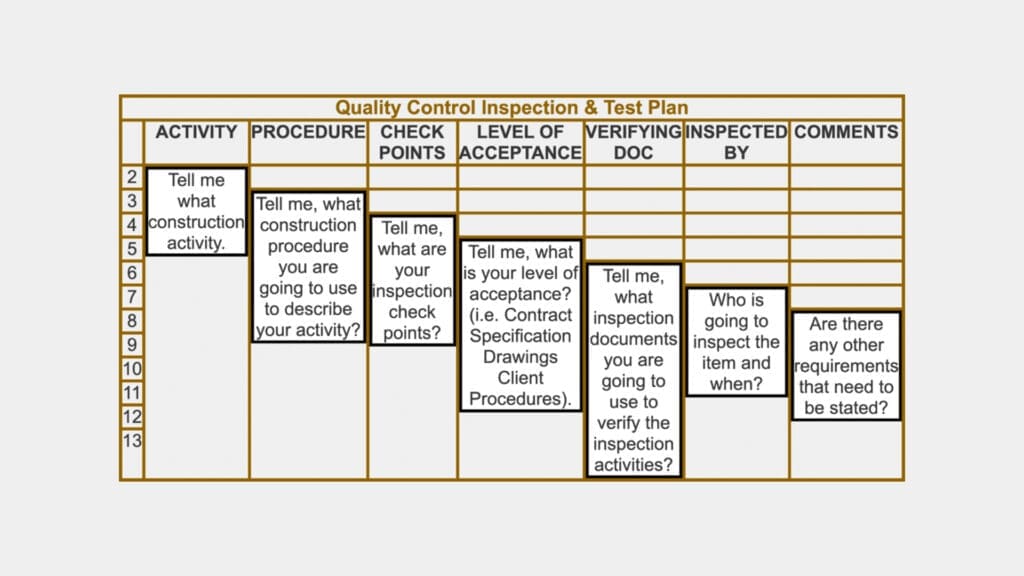

Inspection Test Plan Example

Let’s consider an example of an Inspection Test Plan in the context of a manufacturing process for electronic devices. This example will cover the key stages of the production process and the corresponding inspection activities at each stage.

Product: Electronic Devices (e.g., smartphones)

Receiving Inspection:

Objective: Ensure that incoming electronic components meet quality specifications before they are used in the assembly process.

Activities:

- Verify the accuracy of received components against the purchase order.

- Inspect components for physical damage, proper labeling, and compliance with technical specifications.

- Conduct functional tests on a sample of components to ensure they meet performance criteria.

Work in Process Inspection:

Objective: Monitor and assess the quality of the electronic devices at various stages of the assembly process.

Activities:

- Inspect the assembly line regularly to ensure adherence to standard operating procedures.

- Verify the correct placement of components and connections during assembly.

- Conduct in-process testing of electronic functions (e.g., touchscreen, camera, battery) to identify any defects early in the process.

Resource Inspection:

Objective: Ensure that manufacturing equipment and tools are in optimal condition to maintain production efficiency and product quality.

Activities:

- Conduct regular maintenance checks on manufacturing machinery to prevent breakdowns.

- Calibrate equipment to ensure accuracy in measurements and processes.

- Train and certify operators to use machinery safely and effectively.

Asset Inspection:

Objective: Assess the condition of the production facility and infrastructure to maintain a safe and efficient working environment.

Activities:

- Regularly inspect the facility for compliance with safety regulations and building codes.

- Assess the condition of utilities (e.g., electrical systems, HVAC) to prevent disruptions in production.

- Evaluate the overall cleanliness and organization of the workspace.

Final Inspection:

Objective: Ensure that the finished electronic devices meet all quality standards before they are shipped to customers.

Activities:

- Conduct a comprehensive visual inspection for any cosmetic defects.

- Perform functionality tests on all features of the electronic devices.

- Randomly sample finished products for additional quality checks.

Documentation and Reporting:

- Task List Groups: Organize inspection activities into task list groups for easier management and tracking.

- Characteristics to be Inspected: Clearly define the specific criteria for inspection at each stage.

- Header Information: Document general data, including production dates, batch numbers, and responsible personnel.

- Material Assignment: Link inspection plans to specific batches of electronic devices.

- Vendor/Customer Assignment: Associate inspection plans with customer orders to ensure customer-specific requirements are met.

The Bottom Line

In conclusion, following inspection plans is integral to maintaining product quality, operational efficiency, and continuous improvement. The structured approach of inspection plans not only mitigates risks but also enables businesses to implement corrective actions promptly, fostering a culture of quality and reliability. Embracing inspection plans as a fundamental aspect of quality assurance in Lean Six Sigma contributes to sustained success in manufacturing and production processes.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.