Table of contents

- How to Use a Payoff Matrix to Prioritize Solutions

- What is a Payoff Matrix?

- How does a typical Payoff Matrix work?

- How to Use the Payoff Matrix to Prioritize Solutions?

- Before Prioritizing Improvements

- Setting the Stage for Improvement Prioritization

- Start Prioritizing Improvements

- What is the Meaning of the Four Quadrants?

- Related Articles

Estimated reading time: 7 minutes

How to Use a Payoff Matrix to Prioritize Solutions

In this article, we will teach you how to use a simple tool to prioritize the improvements generated from the Improve phase in the Lean Six Sigma project. The tool is called the Priority Payoff Matrix, and it represents how to prioritize your improvements according to examples of their benefit if implemented and the resources needed to implement them.

What is a Payoff Matrix?

A Payoff Matrix is a decision-making tool used in game theory, economics, and decision analysis. It’s a grid or table that helps visualize and analyze the potential outcomes of different strategies or decisions made by multiple parties involved in a situation. It’s particularly useful when there are multiple options available to each party, and the outcome of each decision depends not only on the decision maker’s actions but also on the actions of others.

How does a typical Payoff Matrix work?

- Identifying the Parties or Decision Makers: Firstly, determine the parties or individuals involved in the decision-making process. For instance, in a business context, it could be two competing companies, or in a negotiation scenario, it might involve two negotiating parties.

- Listing the Strategies/Decisions: Next, outline the possible strategies or decisions each party can make. These decisions are listed as rows and columns in the matrix.

- Assigning Payoffs or Outcomes: Each intersection of a row and a column in the matrix represents the outcome or payoff resulting from the combination of decisions made by the parties involved. These payoffs can be numerical values, representing profits, costs, benefits, or any relevant measure of success or utility.

- Analyzing Payoffs: Parties can then analyze the Payoff Matrix to determine which strategy yields the best outcome based on their preferences or objectives. They may consider different criteria such as maximizing their payoff, minimizing losses, reaching a compromise, or optimizing a collective outcome.

How to Use the Payoff Matrix to Prioritize Solutions?

- Evaluate the Payoffs: Assess the potential outcomes of each decision or strategy. Understand the implications of each choice in terms of gains, losses, benefits, or other relevant metrics.

- Consider Preferences and Objectives: Identify the priorities or goals of each decision-maker involved. This could involve maximizing profits, minimizing risks, achieving a compromise, or reaching a mutually beneficial agreement.

- Select the Optimal Solution(s): Determine the best course of action for each party based on the Payoff Matrix analysis. This might involve selecting the strategy that offers the highest payoff for a single party or finding a solution that balances the interests of multiple parties involved.

- Iterate and Refine: Reassess the Payoff Matrix if circumstances change or new information becomes available. It’s important to adapt the analysis based on evolving situations or changing preferences.

Ultimately, the Payoff Matrix provides a structured way to analyze decision-making scenarios involving multiple options and parties. It helps in understanding the potential outcomes of different choices and aids in selecting the most favorable or optimal solution based on the preferences and objectives of the decision-makers involved.

Before Prioritizing Improvements

Before prioritizing improvements, it’s crucial to conduct a thorough assessment and preparation phase. This phase involves several key steps to ensure that the prioritization process is well-informed and aligned with the overarching goals and needs of the organization.

Review and assess the current state of affairs within the organization. Identify areas that require improvement. This might involve analyzing performance metrics, conducting surveys, gathering feedback from stakeholders, or performing audits to pinpoint inefficiencies, bottlenecks, or areas with the potential for enhancement.

Define clear and specific objectives for the improvement initiative. These objectives should be aligned with the organization’s strategic goals and mission to start to represent the payoff matrix example. Clarify what you aim to achieve through the improvements, whether it’s increasing efficiency, reducing costs, enhancing quality, or improving customer satisfaction.

Evaluate and prioritize improvement areas based on their significance, impact on business goals, urgency, and potential benefits. Some improvement areas might have a higher priority due to their criticality or immediate impact on the organization’s performance.

By thoroughly addressing these steps before initiating the prioritization process, organizations can lay a strong foundation for effectively identifying, evaluating, and prioritizing improvements that align with their strategic objectives and have the potential to drive meaningful positive change.

Setting the Stage for Improvement Prioritization

When utilizing a Payoff Matrix for improvement prioritization, especially in a business context, it’s essential to set the stage properly to ensure a comprehensive and effective analysis.

Once the prioritization is done, develop an action plan that outlines the implementation steps for the selected solutions. Define responsibilities, timelines, and resource allocation for executing these improvements.

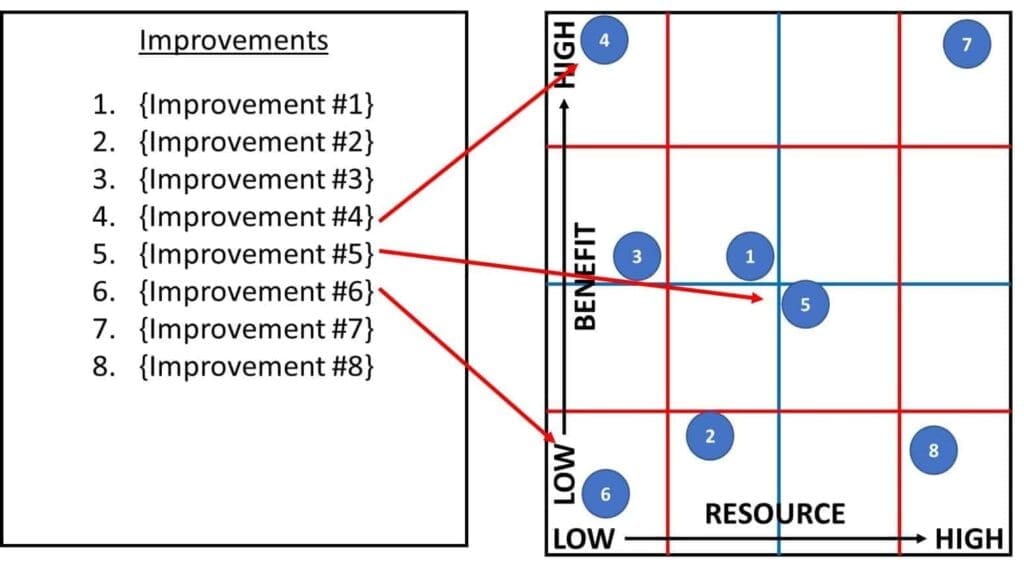

Before we can prioritize the improvements, we need to draw what the priority Payoff Matrix represents. I like to draw the Payoff Matrix on a flip chart to get engagement from the whole team.

Let me take you through the steps to drawing the Payoff Matrix:

- Step 1: With a blue marker draw cross-hairs in the middle of the flip chart.

- Step 2: With a red marker, draw crosshairs in each of the four sections.

- Step 3: Along the X axis draw the Low to High Resource line. Along the Y axis draw the Low to High Benefit line.

Start Prioritizing Improvements

Now that we have drawn the Priority Payoff Matrix example, we can start populating and prioritizing improvements. Use your team’s list of improvements. Start with improvement #1. Place the #1 on the payoff matrix according to the benefit of implementing the improvement and the number of resources to implement. Move on to improvements #2, #3, etc.

Based on the rankings and analysis, select the improvements that offer the highest overall payoff and align with your organizational goals and constraints. Then implement the chosen improvements and regularly review their progress to ensure they meet the expected outcomes.

Tips:

- Ensure criteria are well-defined and measurable.

- Involve stakeholders to assign weights or scores for criteria.

- Consider the potential risks and uncertainties associated with each option.

- Review and update the matrix periodically to adapt to changing circumstances.

A payoff matrix provides a systematic approach to evaluate and prioritize improvements based on their potential benefits, allowing for informed decision-making.

What is the Meaning of the Four Quadrants?

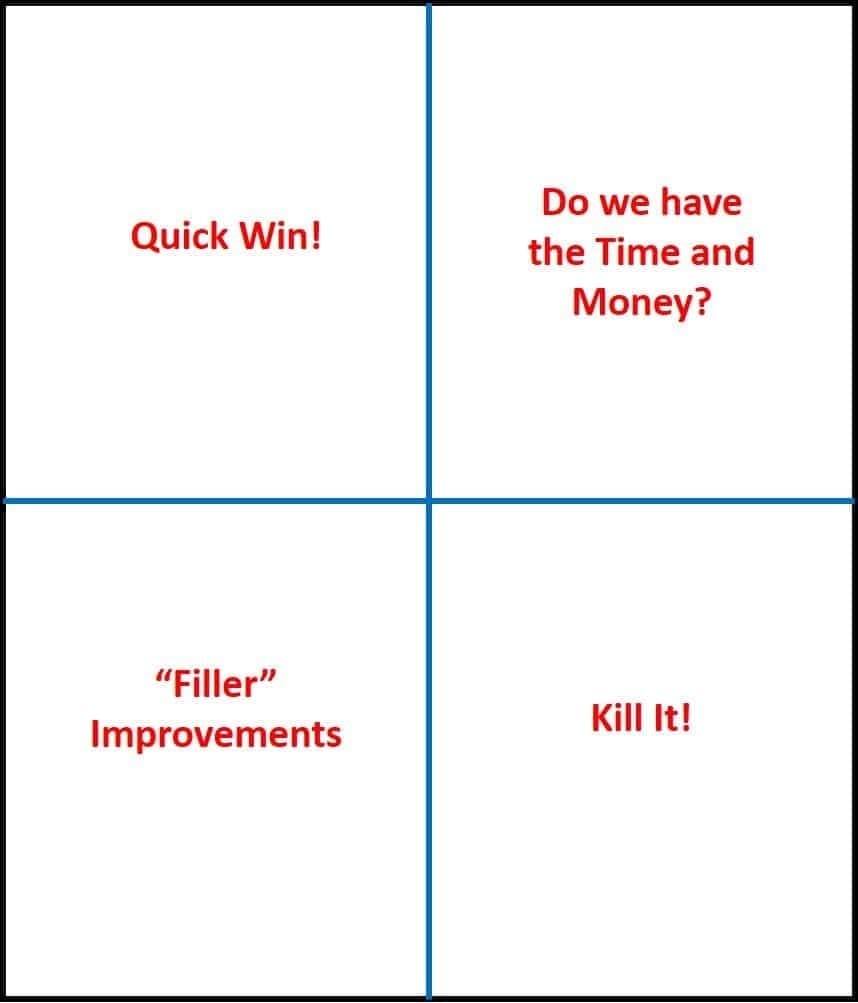

- “Quick Win” Quadrant: These are improvements that are easy to implement and have a relatively high benefit. This is the quadrant that should be the priority when implementing Lean Six Sigma project improvements.

- “Filler” Improvements: The improvements in this quadrant will individually have less effectThe change in the average value of the output caused by a ch… but cumulatively could have a large effect.

- Do we have the Time and Money?: The improvements in this quadrant are costly in time and/or expense. These improvements are where we have to evaluate the risk of giving up the resources and the reward gained.

- “Kill It”: The improvements in this quadrant have little effect and are costly. These improvements are either tabled or we can decide they are not worth pursuing.