The Lean concept, as we understand it today, focuses on the systematic reduction of waste in production processes. While its formalization began in the mid-20th century, the foundational ideas for waste reduction and process improvement have roots that extend far back in history.

Table of contents

- History of Lean Manufacturing

- Benjamin Franklin and Early Thoughts on Waste Reduction

- Scientific Management in the Early 20th Century

- Frank and Lillian Gilbreth’s Time and Motion Studies

- Henry Ford and the Birth of Mass Production

- Ford’s Limitations and the Need for Improvement

- Toyota Production System (TPS) and the Evolution of Lean Manufacturing

- Feature Description Benefit

- Case Study: Toyota Production System

- Role of Employees in Lean Manufacturing

- Spread of Lean Manufacturing Beyond Toyota

- Lean Manufacturing in the Textile Industry

- Challenges and Future of Lean Manufacturing

- Final Words

- Related Articles

History of Lean Manufacturing

Benjamin Franklin and Early Thoughts on Waste Reduction

The seeds of Lean thinking can be traced back to Benjamin Franklin, whose contributions to the reduction of waste date to the 18th century. Franklin’s essay, “The Way to Wealth” (1758), emphasized the importance of efficiency and frugality. Franklin’s principles were about eliminating unnecessary activities and focusing on work that added value.

Though Franklin did not explicitly propose Lean principles, his philosophy of reducing waste and being mindful of time is a precursor to later Lean thinkers.

Scientific Management in the Early 20th Century

In the early 20th century, the scientific management movement took shape as a response to the inefficiencies of traditional manufacturing. Pioneered by Frederick Winslow Taylor, scientific management sought to apply scientific methods to the analysis of work processes.

Taylor advocated for standardizing work methods, establishing clear procedures, and carefully matching workers with jobs suited to their skills. His goal was to maximize efficiency and eliminate wasted effort.

Taylor’s ideas set the stage for future developments in manufacturing efficiency. His focus on labor productivity and efficiency through process optimization was an important precursor to Lean manufacturing. Taylor’s work laid the foundation for a systematic approach to eliminating non-value-adding activities from work processes.

Frank and Lillian Gilbreth’s Time and Motion Studies

Frank and Lillian Gilbreth, pioneers in time and motion studies, further refined Taylor’s work. By observing workers and measuring the time required for each movement, they identified redundant motions that could be eliminated.

They introduced the Predetermined Motion Time Systems (PMTS), which allowed for the optimization of workers’ movements and the identification of inefficiencies in the system. This was a significant step in creating more efficient production systems by systematically eliminating wasteful actions.

Henry Ford and the Birth of Mass Production

The most significant early application of waste reduction in manufacturing came with Henry Ford’s assembly line. Ford’s introduction of the assembly line in 1913 revolutionized the production of automobiles. Ford applied Taylor’s principles of work standardization and productivity but went even further by utilizing a moving conveyor belt to streamline the assembly process.

This allowed him to achieve economies of scale, drastically reduce production times, and cut costs.

In his writings, such as “My Life and Work” (1922), Ford discussed waste in the context of manufacturing. He noted that eliminating unnecessary motion and improving the arrangement of materials could lead to substantial cost reductions.

Ford’s innovations laid the groundwork for modern mass production, although his system had its limitations—chiefly, a lack of flexibility in product variation.

Ford’s Limitations and the Need for Improvement

While Ford’s production system was groundbreaking, it had significant limitations. The most notable was its inability to produce product variations. The Model T, produced from 1908 to 1927, was offered in limited colors and with minimal customization. The rigid production system made it difficult for Ford to adapt quickly to changing customer preferences or introduce new models.

Ford’s reliance on large-scale, standardized production methods left him vulnerable when consumer demands shifted. This realization would later contribute to the development of more flexible production systems, such as the Toyota Production System (TPS), which was designed to address many of Ford’s shortcomings.

Toyota Production System (TPS) and the Evolution of Lean Manufacturing

The next major development in Lean manufacturing came from Toyota in Japan. After the devastation of World War II, Japan’s manufacturing industry was in shambles. With limited resources, Japanese manufacturers needed to find new ways to reduce costs and improve efficiency to survive in the global market.

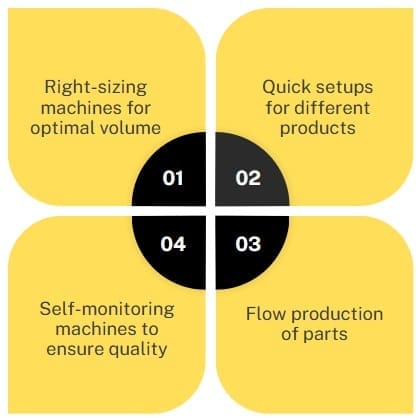

The Toyota Production System (TPS) integrated many innovations, such as:

- Right-sizing machines for optimal volume,

- Quick setups for different products,

- Flow production of parts,

- Self-monitoring machines to ensure quality.

Feature Description Benefit

| Feature | Description | Benefit |

| Just-In-Time (JIT) | Produce only as needed, reduce inventory levels. | Minimizes inventory, reduces costs. |

| Jidoka (Automation) | Stop machines when defects are detected. | Ensures quality, reduces defects. |

| Kaizen | Continuous improvement through small, incremental changes. | Increases efficiency, reduces waste. |

| Respect for People | Empower workers to stop production when problems occur. | Enhances morale, fosters innovation. |

Case Study: Toyota Production System

Just-In-Time (JIT) and Continuous Improvement

At Toyota, a team led by Kiichiro Toyoda and Taiichi Ohno began developing a new manufacturing system known as the Toyota Production System (TPS). This system focused on reducing waste and improving quality through continuous improvement. Two key pillars of TPS were Just-In-Time (JIT) production and Jidoka (autonomation).

Just-In-Time (JIT) emphasized producing only what was needed, when it was needed, and in the right quantity. This minimized inventory and eliminated the waste of overproduction—a problem that had plagued many traditional manufacturing systems.

By reducing excess inventory, Toyota could reduce storage costs and improve cash flow while remaining more flexible in response to changes in customer demand.

Jidoka, or autonomation, focused on the quality of production processes. In the Jidoka system, machines were designed to detect errors and stop automatically when problems occurred. This ensured that defects were identified early in the process, preventing defective products from reaching the customer.

Jidoka empowered workers by giving them the authority to stop production and address issues immediately, further embedding a culture of quality at all levels of the organization.

Role of Employees in Lean Manufacturing

In contrast to traditional hierarchical management systems, TPS emphasized the involvement of every employee in the continuous improvement process. Workers at Toyota were encouraged to suggest improvements and were given the responsibility to stop production if a problem occurred. This participatory approach helped foster a culture of problem-solving and continuous improvement, known as Kaizen.

The success of Toyota’s system was largely due to the fact that it not only focused on reducing physical waste but also on optimizing processes, improving quality, and engaging employees in the process of change. The concept of respect for people was integral to TPS, ensuring that employees were not seen as mere cogs in the machine but as valuable contributors to the overall improvement of the system.

Spread of Lean Manufacturing Beyond Toyota

The success of the Toyota Production System became widely recognized, and industries across the globe adopted the principles of Lean manufacturing. TPS and its Lean principles, including waste reduction, continuous improvement, and just-in-time production, began to be applied in industries outside of automotive manufacturing.

The concept of Lean has since been expanded to various sectors, including healthcare, construction, and even software development.

Lean Manufacturing in the Textile Industry

The textile industry, traditionally characterized by high labor costs and low margins, was an early adopter of Lean principles. Textile manufacturing involves complex processes that require careful management of resources to maintain competitiveness.

By applying Lean techniques, textile manufacturers have been able to improve efficiency, reduce costs, and meet the increasing demand for fast, high-quality production.

One of the key applications of Lean in the textile industry is demand-driven production, which is closely related to the Just-In-Time (JIT) principle.

Instead of producing large volumes of textile products and holding inventory, Lean manufacturing in textiles focuses on producing only what is needed based on customer demand. This minimizes inventory costs and allows for greater flexibility in responding to market trends.

Moreover, Kaizen and continuous improvement practices are integral to Lean in the textile industry. By continually analyzing production processes, identifying bottlenecks, and implementing small incremental changes, textile manufacturers have been able to increase throughput, reduce waste, and improve product quality.

These principles have allowed companies to stay competitive in a rapidly changing global market.

Also See: Lean Six Sigma Certification Programs, Hialeah, Florida

Challenges and Future of Lean Manufacturing

While Lean manufacturing has been widely adopted, it is not without its challenges. One of the major difficulties is achieving the desired cultural shift within organizations. Lean requires full participation from all levels of the workforce, and not all employees may be willing to embrace the changes necessary for Lean to succeed.

In addition, the application of Lean principles can be difficult in industries that require high levels of customization or where demand is highly unpredictable.

The future of Lean manufacturing is likely to involve the integration of digital technologies. With advancements in automation, artificial intelligence, and the Internet of Things (IoT), Lean manufacturing systems will become even more efficient and adaptable.

Real-time data analysis will allow companies to make quicker decisions, and advanced robotics could further reduce the need for human intervention in repetitive tasks.

Additionally, sustainability will become an increasingly important focus of Lean manufacturing. Reducing waste is not just about cutting costs but also about minimizing the environmental impact of production. As businesses become more conscious of their ecological footprint, Lean practices can play a critical role in driving green manufacturing and sustainable practices.

Final Words

Lean manufacturing evolved through a series of innovations that emerged from the early work of thinkers like Benjamin Franklin, and the breakthroughs of Taylor, Gilbreth, and Ford. Toyota’s development of the Toyota Production System integrated these ideas into a comprehensive approach that focuses on waste reduction, continuous improvement, and quality control.

This philosophy has had a lasting impact on manufacturing and continues to shape modern practices across industries today.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.