Table of contents

What is Lean Thinking: Principles, Benefits & More

You probably think of a process when you hear the term Lean thinking. Lean thinking’s principles are not just about a process, although that is the core of it. It is is an overall business philosophy which can be used by any type of organization or business to achieve better results and more success.

The principles of lean thinking are widely used in manufacturing and engineering, but they can be applied to any business. Lean thinking is used by most companies in many industries to improve processes and their bottom line.

What is Lean Thinking?

Lean thinking can be defined as a business method. Lean thinking is a business methodology that has its roots in the Japanese manufacturing history. It was then applied to organizations and industries around the globe. As the name suggests, lean thinking is also a way of thinking. Lean thinking is a way of looking at the world and handling work. The customer’s value is the main focus.

Lean thinking goes beyond using specific tools and tweaking some steps in a process. It’s about changing the way you view your business. Lean thinking is a new worldview adopted to alter the way people think about their business.

The Beginning of Lean

Toyota is the originator of Lean. The Japanese-owned Toyota Production System was founded to create a productive, sustainable working environment where they could keep costs low and guarantee efficient processes. They were also able sell high-quality products at competitive prices.

When businesses produce more, their quality products seem to suffer. Lean thinking changes this. Lean thinking allows organizations to identify and eliminate wasteful processes in their business, resulting in higher quality products and reduced time wasted. Toyota’s lean philosophy focuses on hard work, prioritizing customer value, and striving for that value with every product and service.

Two Pillars of Lean

You can learn more about lean by understanding the two lean pillars.

- Continuous improvement: This means that each member of your team is actively looking for opportunities and executing initiatives that will change the work in a positive way. Your industry will determine what you consider “better”, but this pillar can help you improve team productivity and employee satisfaction.

- Respect for people: Respecting others is essential to any successful organization or team. People who are able see each other as unique individuals with their own goals, dreams and needs can practice empathy. Respecting people (including customers, employees, and anyone else) in a lean organisation means giving everyone autonomy to do their jobs. It means that you are confident in those around you. This boosts morale and shows trust.

Business owners who base their thinking on this foundation are better equipped to make and implement smarter decisions and strategies. Adhering to lean principles will ultimately result in more efficient systems for your business.

What is the goal of lean thinking?

Lean thinking aims to improve business, to value each other, and to focus on the value of customers. Lean thinking will be fully implemented when you achieve these goals.

In a lean organisation, employees respect their superiors and colleagues through collaboration, clear communication, and quality assurance. It means that the skills, limitations, output, and capacity of each member are equally managed so that everyone is able to bear the same burden.

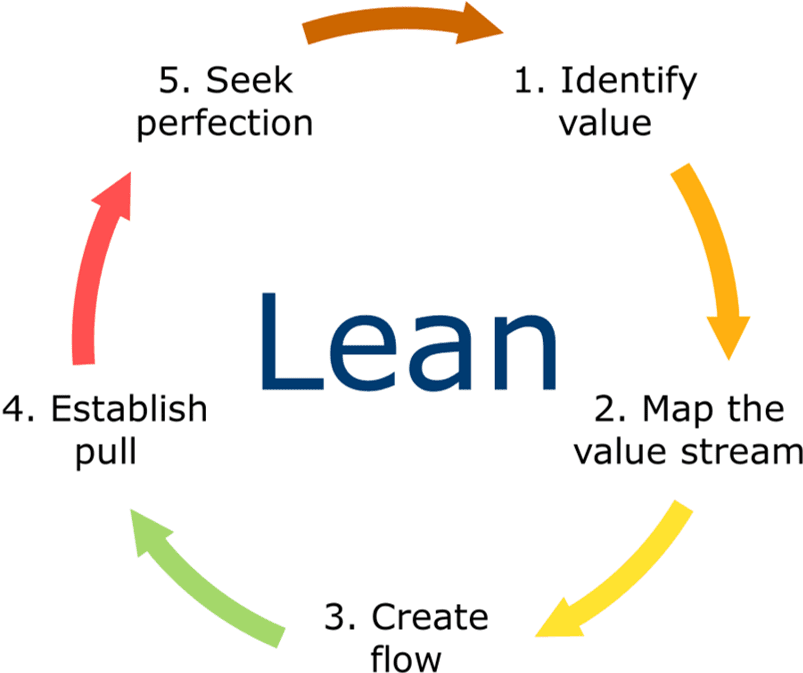

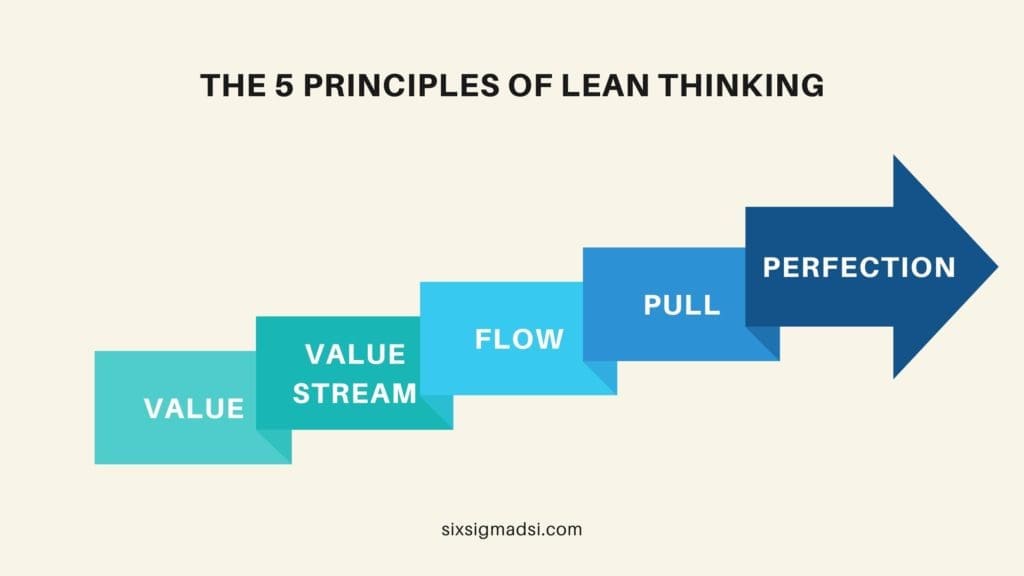

The 5 Lean Thinking Principles

James Womack founded the Lean Enterprise Institute, and Dan Jones founded the Lean Enterprise Academy. The two business partners wrote the book Lean Thinking: Banish waste and Create Wealth in Your Corporation.

The 1996 publication, considered by many as the “bible” for lean manufacturing was the result of Womack and Jones’ intensive study of the Toyota Production System’s remarkable successes. The book outlines the five principles of lean thinking, as well as the goal.

1. Value

Value is the first principle of lean thinking, and it requires organizations to understand what value really means for their clients. You can only provide value once you have identified it. Without value, the other four principles are impossible to implement.

2. Value Stream

After identifying value, the organization must then learn how to create that value. Alternatively, organizations need to identify the various steps that transform raw materials and ideas into products and services customers can use.

3. Flow

After identifying the value stream you can then move onto the next principle of lean thinking: flow. If flow is established, your work will not be slowed down or blocked. It is not easy to establish flow. You may need to implement and introduce changes in your organization, which may initially be unpopular and difficult. Lean thinking is based on continuous improvement driven by a common goal. Even though getting into flow can be stressful, a united organization will benefit from it.

4. Pull

Once you have eliminated waste, other problems, and got your flow flowing smoothly, the time to market is low. It may not sound good, but this is actually a positive thing. Customers will “pull” products when they are needed, instead of having them sit in stock. Your customers can now easily pull the products they need, thereby satisfying their needs while saving you money on unused inventory.

5. Perfection

Perfection is the last principle in lean thinking. Your organization must have undergone a complete lean transformation to reach perfection. You’ve identified the value correctly, refined and streamlined the value stream, ensured smooth flow and met the customer needs with the right products at the right times. Perfection is not a goal, but a journey. Your organization should always strive for it.

Lean Thinking has evolved and its history is fascinating

Lean Thinking has existed for over fifty years. The earliest versions of the philosophy’s history originated in Japan after World War II. The roots are based on the idea that waste can be eliminated and business processes optimized by streamlining workflows and reducing costs. It was initially heavily used in the manufacturing industry, but quickly spread to other sectors such as customer service, retailing, and product development.

Ready to become a Lean Six Sigma professional?

We can help you get there! Leave us a comment down below.