Table of contents

What I learned about Lean Visual Signals from the Waffle House

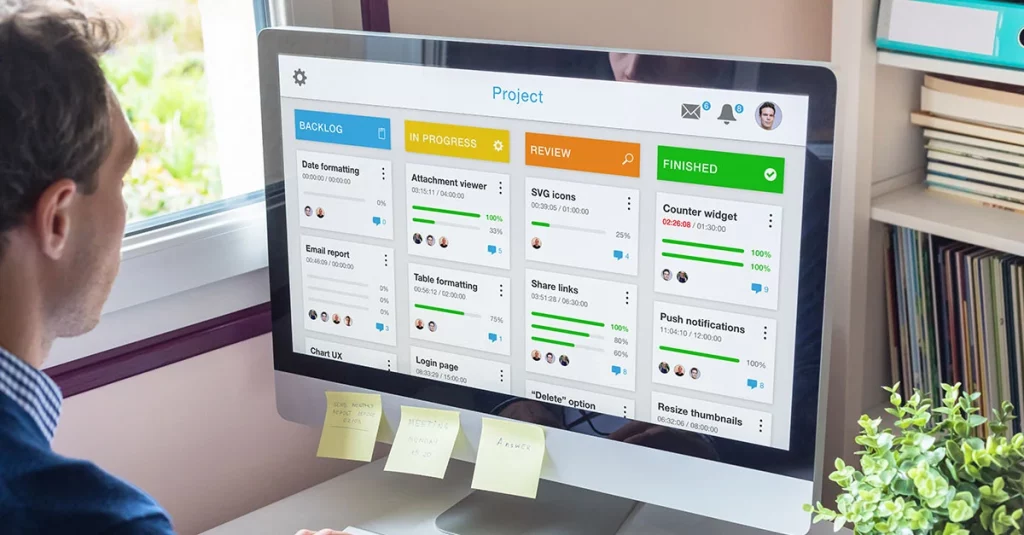

A kanban chart is a Japanese tool meaning signboard or billboard and is referred to in Lean as Visual Signals. In our Public and Onsite Lean courses, we learn the type of data prevalent in a Lean environment. This type of data is called “visual data”. The Lean Visual Signals help them to understand their performance level in real-time through metrics like TAKT time, TAKT time, and Pull Systems. In a Lean environment, we want the operator to “add value” to the product or service. We do not want him or her performing steps like stopping to look at a schedule, filling out a report, moving away from the product or service to retrieve material or information, etc.

Instead of stopping to perform Non-Value Added activities, we want operators to be adding value while the information is displayed and updated in real time in front of them in the form of Lean Visual Signals like the kanban chart tool does. The Lean Visual Signals let’s them understand their current environment. The Lean Visual Signals help them to understand their performance level in real time through metrics like TAKT time and Pull Systems. The Lean Visual Signals help them to understand “What’s Next” without having to stop to investigate a schedule. Many companies use complicated and costly digital systems to attempt this. I happened upon one company that achieved a highly effective solution for Visual Data simply by using condiments.

How does the cook remember all those orders?

I was sitting in a Waffle House and was enamored by the Cook’s ability to memorize multiple orders that were “called out” by waitresses. I was eating breakfast with my wife, who was getting a little upset at my focus on this process. I knew that memorizing that amount of orders was not a easy task. It took me a few minutes, but I noticed that there were plates lined up in sequence of the orders. Condiments were placed on each of the plates. At first I thought that the condiments were placed in random order on the plates and were there as a kind of “prepping” for the final good. All of the sudden, I noticed the consistency of where the condiments were on the plate. I noticed three plates that were set up the same way. I waited until their was another set of similar orders to confirm my hypothesis. The placement of condiments on the plate was the Visual Data that let the Cook know “what was next” or what were the details of the order.

“Simplify, Innovate, Automate”

We teach a hierarchy of improvements in our Lean and Six Sigma courses. The Hierarchy is “Simplify, Innovate, Automate”. Of the three, Simplify is the easiest and in most cases costs nothing. Most companies skip this step and jump straight to Automate (which in most cases is cost intensive). I have witnessed many companies implement MRP and/or ERP systems in order to streamline complex (broken) processes. These companies find out afterwards that the new system just adds to the complexity and therefore lengthens lead time.

Waffle House followed the hierarchy of improvements. They improved the process by asking “how can we implement a visual signal informing us ‘what’s next’ by using what we have on hand.” The answer was as simple as condiments.

Now I challenge you to look for Lean Visual Signals…

I challenge you to visit a Waffle House and observe their ordering process. Come back to this article and leave in the comments how a particular order was communicated by placement of condiments.

Great example for visual signal. Can I use your example for one of my upcoming presentations here in Germany.

I am a lean coordinator for SME and my credo is to start lean just with common sense, rather than ordering a bus load of Mc Kinsey kids

Gerhard

Gerhard, Thank you for the compliment. Yes, you may use the example for your upcoming presentation in Germany.

Regards,

Kevin Clay, MBB

I often use a Waffle House menu in my classes do demonstrate the visual systems utilization. This is done in my lean Six Sigma training program, BOOT CAMP. One of my students brought a menu to me for this purpose. The color photos on the laminated menus allow everyone to order from a visual manner regardless of the ability to read the English language.

I love Waffle House. We don’t have them out here in Seattle.

I like your simplify, innovate, automate.

A quick Google search found several references with the terms in a different order (innovation at the end), but I agree with your ordering as the Pareto principle will get you every time, so why not get the biggest incremental innovations built into your automation instead of changing everything around after the fact.

Keep innovating!

Braden (@innovate)

Kevin, excellent observation by you and elegant solution by Waffle House. My dad loved to go there every week (or more frequently if he could get away with it). He noticed that same thing and brought it to my attention years ago. Your posting gets much better visibility!

Christopher, Thank you for the compliment. What a great memory to share about your Dad.