Table of contents

Estimated reading time: 8 minutes

The Complete Guide to Process Map Icons

Welcome to the comprehensive guide on process map icons! If you’re delving into Lean Six Sigma methodologies or seeking ways to streamline processes, understanding process map symbols is crucial. This article will delve into the realm of process mapping icons, offering insight into their significance, varieties, and how to effectively utilize them to optimize workflows.

What is a Process Map in Lean Six Sigma?

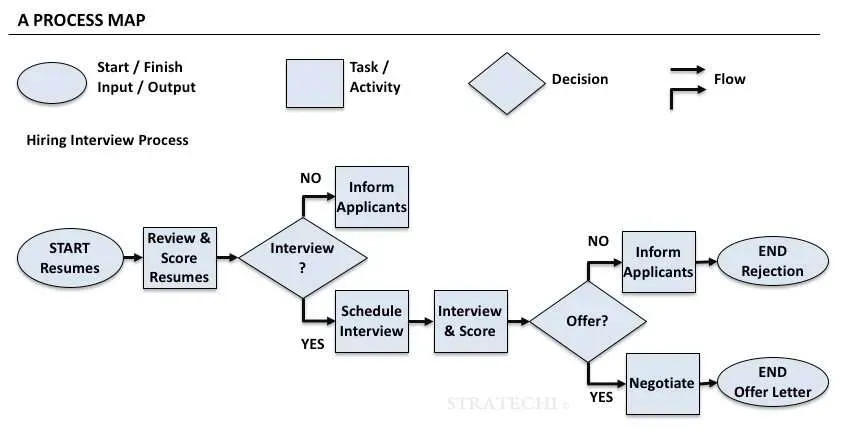

In Lean Six Sigma, a process map is a visual representation or diagram that illustrates the steps, activities, interactions, and flow of a specific process within an organization. It serves as a detailed blueprint or roadmap, offering a clear and structured overview of how a process operates from start to finish.

The primary purpose of creating a process map in Lean Six Sigma is to:

- Visualize Workflows: Process maps provide a visual depiction of complex workflows, making it easier to understand the sequence of tasks, decision points, inputs, outputs, and interactions involved in a process.

- Identify Inefficiencies and Waste: By mapping out a process, Lean Six Sigma practitioners can identify bottlenecks, redundancies, delays, or areas where resources are underutilized, thus enabling the identification of inefficiencies and waste within the process.

- Standardize Processes: Process maps help in establishing standardized procedures and best practices. They ensure that everyone involved in the process understands their roles and responsibilities, fostering consistency and reducing variations in execution.

- Facilitate Improvement: Understanding the current state of a process through mapping allows organizations to brainstorm and implement improvements. It serves as a foundation for continuous improvement efforts within Lean Six Sigma methodologies.

- Enhance Communication and Collaboration: Process maps serve as a communication tool, aiding in effectively conveying complex processes to various stakeholders. It encourages collaboration among teams and departments by providing a shared understanding of how processes function.

- Support Decision-Making: Visualizing processes through maps assists in making informed decisions about where to allocate resources, which areas need improvement, and how to optimize workflows for better efficiency and quality.

In essence, process maps in Lean Six Sigma are pivotal tools that enable organizations to analyze, streamline, and optimize their operations systematically. They promote a structured approach to problem-solving, continuous improvement, and achieving operational excellence by focusing on eliminating waste and enhancing value for customers.

Process Map Symbols & Icons

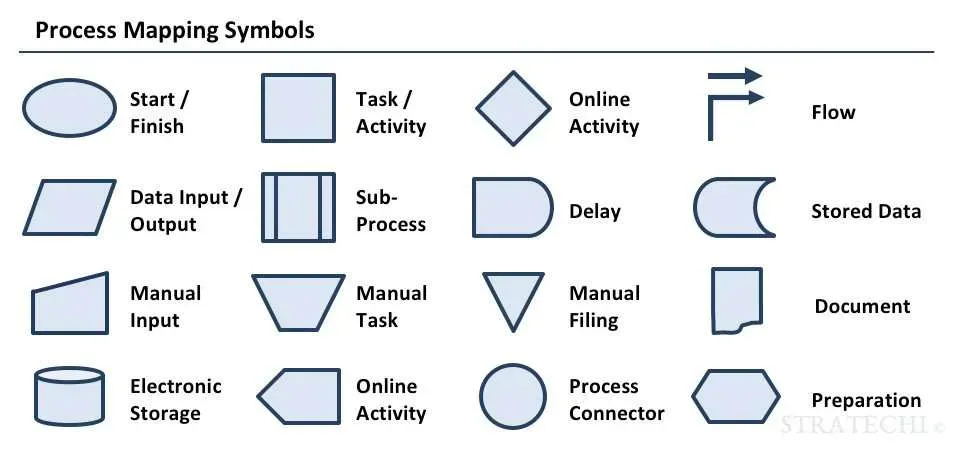

Process map icons are graphical symbols or representations used in process mapping to visually illustrate different elements, activities, decisions, inputs, outputs, and connections within a process. These icons serve as a standardized set of visual cues that convey specific meanings, making it easier to comprehend and communicate complex workflows.

These icons are categorized and used to represent various components of a process. Each category of icons signifies a different aspect or element within the process map, aiding in the clear depiction of the sequence of tasks, decision points, and flow of information or materials.

Activity and External Activity Symbols

Activity symbols are graphical representations used in process mapping to indicate specific tasks, actions, or operations within a process. These symbols are fundamental in illustrating the sequence and nature of activities performed within a workflow. They typically include basic shapes such as rectangles, circles, ovals, or other geometric figures, each representing different types of activities.

Common activity symbols include:

- Rectangle: Often used to represent a specific task or operation within the process. It signifies an action or step that needs to be carried out.

- Circle or Oval: These symbols may indicate the start or end points of a process. They represent the initiation or conclusion of a series of activities.

- Rounded Rectangle: Sometimes utilized to represent a subprocess or a group of related tasks within the overall process.

External Activity Symbols, on the other hand, indicate activities that are performed outside the scope of the current process but are relevant to its workflow. These symbols represent tasks or operations carried out by external entities, such as suppliers, customers, or other departments, that directly impact or interact with the process being mapped.

For instance, an arrow entering or leaving an activity symbol might denote an interaction with an external entity, signifying the input received from an external source or the output delivered to an external recipient.

These symbols help illustrate the dependencies, interactions, and handoffs between the current process and external factors, providing a comprehensive view of how the process interacts with its environment.

Connectors and Off-page Connector Symbols

Connectors and Off-page Connector Symbols are graphical representations used in process mapping to depict the flow, sequence, connections, and relationships between different elements within a process map. These symbols play a vital role in illustrating the direction, order, and continuity of activities, decision points, or subprocesses within a complex workflow.

Connectors:

Connectors are graphical elements that signify the logical flow or sequence between various steps, activities, or decision points in a process map. They visually link different symbols or shapes representing activities, decisions, inputs, outputs, or other elements within the process. Common types of connectors include arrows, lines, or flowchart lines with directional indicators (such as arrows pointing in a specific direction).

Connectors showcase:

- The order of tasks or steps within a process.

- The relationship between different process elements.

- The direction of the workflow, indicating the sequence of actions or decisions.

Off-page Connector Symbols:

Off-page connector symbols represent connections or continuations of a process map onto another page or section. They indicate that a particular part of the process extends beyond the current page or diagram and continues elsewhere in the documentation. These symbols ensure that the mapping of a process remains coherent and comprehensive even when the entire process cannot be accommodated within a single diagram or page.

Off-page connector symbols often include a label or reference to indicate where the continuation of the process can be found, linking the current section of the process map to its subsequent or previous parts.

Input & Output Symbols

Input Symbols:

Input symbols denote the materials, data, or information required for a specific task or activity within the process. These symbols typically signify the starting point of a process and showcase what is needed to initiate or complete a task. Common input symbols include:

- Arrows or Incoming Flows: These symbols indicate the entry of materials, data, or resources into a particular activity or process step.

- Parallelograms or Rectangles with Rounded Corners: These shapes represent inputs such as raw materials, information, or resources required to carry out a task.

Output Symbols:

Output symbols represent the results, products, services, or information generated as a result of completing a task or activity within the process. These symbols illustrate the outcomes and deliverables produced by the process. Common output symbols include:

- Arrows or Outgoing Flows: These symbols indicate the exit or output of materials, data, or resources from a particular activity or process step.

- Parallelograms or Rectangles with Rounded Corners (similar to input symbols): These shapes signify the outputs generated, which could be final products, information, reports, or services resulting from completing a task.

Effectively utilizing these symbols ensures clarity in demonstrating the flow of materials or information throughout the process, enabling stakeholders to comprehend the inputs required and the outputs generated at each stage of the workflow.

Decision Symbols

Decision symbols in process mapping represent points in a workflow where a decision needs to be made. These graphical icons indicate branches or diverging paths in the process based on certain conditions, criteria, or choices. They are crucial elements in illustrating decision points within a sequence of activities, helping to visualize different possible outcomes or paths that can be taken.

The most commonly used decision symbol in process mapping is the diamond shape. This diamond symbolizes a decision node, where the process flow can take alternative routes depending on the conditions or choices specified. Within the diamond shape, text or a description is usually included to clarify the decision being made.

Deliverable and External Deliverable Symbols

Deliverable symbols highlight the products, services, or results generated by a process. These icons clarify the tangible outcomes or outputs produced. External deliverable symbols signify outputs that leave the process boundaries, impacting external stakeholders or processes.

Data Symbols

In process mapping, data symbols are graphical representations used to depict the handling, storage, manipulation, or transformation of data within a workflow or process. These symbols are essential for indicating points in a process where data is collected, processed, stored, or retrieved.

Data symbols help visualize how data moves, is used, or transformed within a process. They facilitate the understanding of information flow, data manipulation, and storage points, providing clarity on where data-related activities occur in the overall workflow.

How to Create a Process Map in Lean Six Sigma

Creating a process map involves several steps:

- Identify the Process: Choose the process you want to map and define its boundaries.

- Gather Information: Collect data from stakeholders involved in the process.

- Select Appropriate Symbols: Utilize the relevant process map icons to represent each step or activity accurately.

- Sequence the Steps: Establish the logical order of activities, connections, decisions, and outputs.

- Review and Refine: Collaborate with stakeholders to review the map for accuracy and clarity, making revisions if necessary.