The Machine Capability Index (Cmk) is a critical metric in manufacturing. It measures a machine’s short-term ability to produce items within specified tolerances. The metric helps manufacturers ensure their machinery is operating efficiently and producing quality products.

The Machine Capability Index, known as Cmk, measures a machine’s precision. It evaluates how well a machine produces items within set tolerances. This index is vital in manufacturing and quality control.

This guide explains the concept, calculation, importance, interpretation, differences from similar metrics, and ways to improve machine capability.

Table of contents

Definition of Cmk

The Machine Capability Index, abbreviated as Cmk, evaluates a machine’s performance accurately and consistently. It considers two key aspects:

- Accuracy: How close the machine’s output is to the target value.

- Precision: How consistently the machine produces results within tolerance limits.

Cmk is primarily used to assess short-term machine performance. It is typically measured over a small sample size, ensuring that the analysis focuses only on the machine’s capability, free from external influences like operator variability.

Cmk assesses a machine’s short-term performance. It shows how consistently a machine operates within specified limits. A higher Cmk value indicates better machine capability.

Why Is Cmk Important?

Cmk plays a vital role in manufacturing quality control. Here’s why:

- Ensures Quality: It helps manufacturers determine if a machine produces products within acceptable limits.

- Reduces Defects: A high Cmk indicates fewer defective products.

- Improves Efficiency: Understanding Cmk allows timely adjustments, improving production efficiency.

- Supports Decision-Making: Cmk results guide investments in machine upgrades or maintenance.

- Builds Customer Trust: Consistently capable machines ensure reliable product quality, enhancing customer satisfaction.

Key Components of Cmk

Mean (μ)

The mean is the average value of measurements taken from the machine. It represents the central tendency of the data.

Standard Deviation (σ)

The standard deviation measures the spread of data. A smaller standard deviation indicates more consistent output.

Specification Limits

- Upper Specification Limit (USL): The maximum acceptable value for the product.

- Lower Specification Limit (LSL): The minimum acceptable value for the product.

Calculating Cmk

To calculate Cmk, follow these steps:

- Collect Data: Gather 20 to 50 consecutive measurements from the machine.

- Determine Mean (μ): Calculate the average of these measurements.

- Calculate Standard Deviation (σ): Find the standard deviation to understand data spread.

- Identify Specification Limits: Note the Upper Specification Limit (USL) and Lower Specification Limit (LSL).

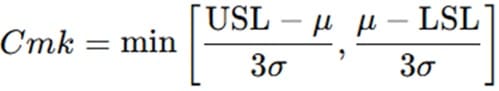

- Compute Cmk: Use the formula:

Cmk = min[(USL – μ) / (3σ), (μ – LSL) / (3σ)]

This formula considers both the machine’s accuracy and precision.

Formula for Cmk

The formula for calculating the Machine Capability Index (Cmk) is:

Explanation of Terms:

- USL: Upper Specification Limit.

- LSL: Lower Specification Limit.

- μ: Mean of the sample data.

- σ: Standard deviation of the sample data.

- 3σ: Represents three standard deviations, which cover 99.73% of data in a normal distribution.

How to Calculate Cmk?

Step-by-Step Calculation:

- Collect Data: Gather 20–50 consecutive measurements from the machine under normal operating conditions.

- Calculate the Mean (μ): Add all measurements and divide by the number of observations.

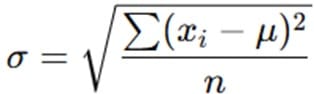

- Find the Standard Deviation (σ): Use the formula:

Where:

- xix_ixi: Individual measurements.

- μ\muμ: Mean of the measurements.

- nnn: Total number of observations.

- Determine Specification Limits: Identify the USL and LSL based on design requirements.

- Apply the Formula: Plug the values into the Cmk formula to compute the index.

Difference Between Cmk and Cpk

While both indices assess capability, Cmk focuses on individual machines over the short term. In contrast, Cpk evaluates the entire process over a longer period. Understanding both is crucial for comprehensive quality control.

Cmk and Cpk are often confused, but they serve different purposes:

| Aspect | Cmk | Cpk |

| Scope | Focuses on machine performance. | Evaluates overall process performance. |

| Timeframe | Short-term. | Long-term. |

| Influence Factors | Considers only machine capability. | Includes factors like operator variability. |

| Application | Used for machine-specific analysis. | Used for process-level analysis. |

Interpreting Cmk Values

- Cmk ≥ 1.67: The machine is highly capable.

- 1.33 ≤ Cmk < 1.67: The machine is capable but may need improvement.

- Cmk < 1.33: The machine is not capable; corrective actions are necessary.

Importance of Cmk in Manufacturing

Cmk helps ensure product quality by verifying machine performance. It identifies machines that may produce defects, allowing for timely interventions. Regular Cmk assessments lead to consistent production and customer satisfaction.

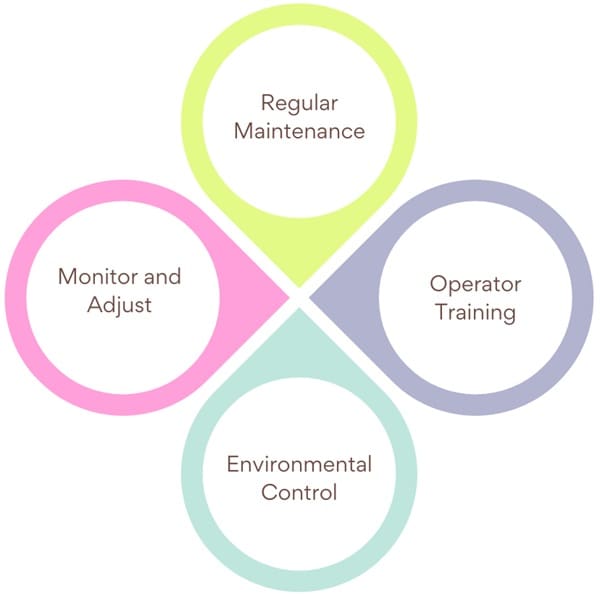

Steps to Improve Cmk

- Regular Maintenance: Keep machines in optimal condition to maintain precision.

- Operator Training: Ensure operators are skilled and understand machine functions.

- Environmental Control: Maintain a stable environment to reduce variability.

- Monitor and Adjust: Continuously monitor performance and make necessary adjustments.

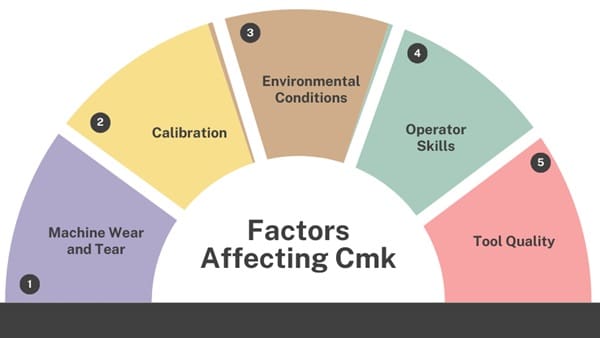

Factors Affecting Cmk

Several factors influence Cmk values:

- Machine Wear and Tear: A worn-out machine reduces precision.

- Calibration: Incorrect calibration affects accuracy.

- Environmental Conditions: Temperature, humidity, and vibrations impact machine performance.

- Operator Skills: Improper handling can lead to inconsistent results.

- Tool Quality: Substandard tools affect the machine’s ability to meet tolerances.

How to Improve Cmk?

Improving Cmk requires systematic efforts. Here are actionable steps:

- Regular Maintenance: Keep machines well-maintained to ensure consistent performance.

- Calibration: Machines are periodically calibrated to maintain accuracy.

- Operator Training: Train operators to handle machines correctly and interpret results.

- Upgrade Equipment: Invest in modern equipment with better precision and reliability.

- Control Environment: Minimize external factors like temperature or vibration that may impact performance.

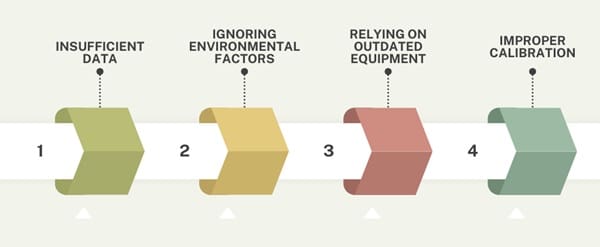

Common Mistakes in Cmk Measurement

- Insufficient Data

Using too few measurements leads to unreliable results. - Ignoring Environmental Factors

External conditions can skew results if not accounted for. - Relying on Outdated Equipment

Old machines may fail to meet modern quality standards. - Improper Calibration

Uncalibrated machines produce inaccurate data, affecting Cmk calculations.

Cmk Standards in Quality Control

Industry standards often define acceptable Cmk values:

- Automotive Industry: Many manufacturers require Cmk ≥ 1.67 for critical processes.

- Medical Devices: High Cmk values ensure patient safety and regulatory compliance.

- ISO Standards: ISO 9001 emphasizes monitoring machine capability for quality assurance.

Final Words

The Machine Capability Index (Cmk) is an essential tool in manufacturing. It ensures machines produce high-quality products consistently. By understanding and monitoring Cmk, manufacturers can identify issues, make necessary adjustments, and improve overall efficiency.

Regular assessments, combined with proactive measures, ensure machines operate at their full potential. A focus on Cmk ultimately leads to higher customer satisfaction, reduced costs, and a competitive edge in the market.